12

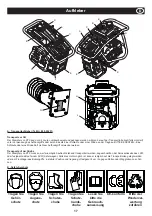

Operation

GB

Lifting

Where it is necessary to use lifting equipemnt to position the

RTX

, check and confi rm that the rubber mounts on the operation

handle are not damaged or cracked. If they are damaged or cracked, replace the rubber mounts before attempting to lift the machine.

Also make sure that the lifting equipment has a WLL (Working Load Limit) suitable for the

RTX’s

weight (See specifi cation chart or the

machine Serial Plate). Attach suitable chains or slings

ONLY

to the lifting point on top of the

RTX’s

operating handle.

•

NEVER

leave the engine running whilst transporting or moving the

RTX’s

, even if it is only a short distance.

Once the checks listed in the ‘Pre-Start’ section have been carried out, you may start the engine.

The Altrad Belle

RTX

range of tampers are fi tted with a centrifugal clutch, this allows the engine to run at idle without driving the crank

mechanism. As the engine speed is increased the clutch will engage and the engine will drive the crank mechanism.

•

To avoid damage to the centrifugal clutch, move the throttle lever quickly from the L to H position.

Trouble Shooting Guide

GB

Problem Cause

Remedy

Engine will not start

No fuel

Fill Fuel Tank

Fuel Tap has been closed

Open fuel tap.

Engine not primed

Push the Carburettor Primer Bulb 4 times and

pull the Recoil Handle until the Engine fi res

(GX100

only)

Spark Plug contaminated

Replace spark plug.

or

damaged.

Faulty Carburettor

Service the Carburettor

Engine stops suddenly, or stops when the

See Above

See Above

engine rpm is increased

Main jet of the Carburettor

Take out the main jet of the Carburettor and

clogged with dirt

clean with Compressed air. (GX120 only)

Air

fi lter element dirty

Clean the element.

Spark plug cap is loose

Tightly fi t cap to plug.

Engine runs, but machine does not produce impact.

Lack of engine power

See above.

Clutch is slipping

Dismantle clutch assembly, Clean shoe

and drum with proper solvent. Replace

clutch shoe if necessary.

Crank mechanism is damaged Contact Dealer.

For correct operation, the engine speed should be set to maximum.

CAUTION

•

Avoid operating the machine on a fully compacted, hard, or non-yielding surface. Otherwise, the gear transmission mechanism

will be damaged, and the life of the machine will be greatly reduced.

•

When working in a narrow trench, if the ramming shoe should get caught between the walls of the trench, the rammer may

miss-strike and can be severly damaged. The ramming shoe may especially be damaged severely.

•

Ensure that the rammer is steered only by using the handle grip. It should only be pushed. The rammer must not be pressed

into the materials being compacted. Excessive pressure on the operating handle will lead to unsatisfactory compaction due to

the fact that the jumping action is reduced.

Transportation.

When transporting or storing the machine, place the machine in an upright position if at all possible. Should the machine be required

to be laid down,

NEVER

attempt to transport the machine in a manner that the air cleaner faces downwards. Otherwise, the oil in the

cylinder may get into the combustion chamber or in the air cleaner, which may result in starting diffi culties. Laying the machine forwards

(The crankcase cover of the rammer facing downwards) may not cause any spill of the engine oil into the cylinder or air cleaner of the

engine. However, if the engine is still hot, spilt fuel on the engine may cause fi re. Lay the machine after the machine is completely

cooled.

The machine fi tted with the transporting roller on the operating handle may be easily loaded and unloaded from a vehicle. Tilt the

machine forwards until the transporting roller touches the fl oor of the vehicle. Lift the lower part of the machine using the grab handle

provided at the ramming shoe, and push forward to load the machine. During transportation, the machine should be tied fi rmly, and

placed in an upright position if at all possible. To unload the machine, tilt the machine forward, until the roller touches the fl oor. Slightly

lift the lower part of the machine, and pull the machine out.

Operation at High Altitude

For continuous High-Altitude operation above 1,000m (3,000FT), it will be necessary to change the engine main jet to a type that will

allow for correct fueling of the engine. Otherwise, the unit will suffer from a lack of engine power and not work correctly.