• Make sure that the installation area is protected from any fluid

leaks, or flooding.

• If possible, place the pump slightly higher than the floor level.

• Provide shut-off valves on the suction and discharge sides of the

pump.

• The relative humidity of the ambient air must be less than 95%

non-condensing.

• This pump is suitable for indoor use only.

CAUTION:

CAUTION: PROPERTY DAMAGE HAZARD. It is not advisable

to install circulators in an attic or upper floor over finished liv-

ing space. If the circulator must be installed over head, or

over expensive equipment, provide adequate drainage in

the event of leakage. Failure to follow these instructions

could result in property damage.

4.3.2 Minimum inlet pressure at the suction port

The values in the table below are the inlet pressures above the atmos-

pheric pressure.

Nominal Suction

Diameter

Fluid tempera-

ture 77°F (25°C)

Fluid tempera-

ture 203°F

(95°C)

Fluid tempera-

ture 230°F

(110°C)

1½”

4.5 PSI

16 PSI

25 PSI

2”

4.5 PSI

16 PSI

25 PSI

3”

7.5 PSI

19 PSI

28 PSI

NOTICE:

• Ensure that the suction pressure is never below the values speci-

fied above, as this could cause cavitation and damage the pump.

• The inlet pressure plus the pump pressure against a closed valve

must be lower than maximum admissible system pressure.

4.3.3 De-rating table

The following table indicates percent decrease in input power draw,

with the increase in temperature of circulating water and the ambient.

Ambient

temperature

Fluid Temperature (°C)

-10

60

95

110

32°F–77°F

(0°C–25°C)

100%

100%

100%

100%

86°F (30°C)

100%

100%

80%

70%

104°F (40°C)

100%

100%

70%

55%

4.3.4 Piping requirements

Precautions

CAUTION:

• Use pipes suited to the maximum working pressure of

the pump. Failure to do so can cause the system to rup-

ture, with the risk of injury.

• Make sure that all connections are performed by quali-

fied installation technicians and in compliance with the

regulations in force.

• Do not use a shut-off valve on the discharge side in the

closed position for more than a few seconds. If the

pump must operate with the discharge side closed for

more than a few seconds, a bypass circuit must be instal-

led to prevent overheating of the water inside the

pump.

Piping checklist

• Pipes and valves must be correctly sized.

• Pipe work must not transmit any load or torque to pump flanges.

• Be sure to minimize any pipe-strain on the pump:

• Support suction and discharge piping by the use of pipe

hangers near the pump.

• Line up the vertical and horizontal piping so that the bolt-

holes in the pump flanges match the bolt-holes in the pipe

flanges.

• Do not attempt to spring the suction or discharge lines in po-

sition. This may result in unwanted stress in the pump body,

flange connections and piping.

• The code for pressure piping (ANSI B31.1) lists many types of

supports available for various applications.

4.4 Electrical requirements

• The NEC and local codes must be followed at all times. If a branch

circuit is fitted with ground fault circuit breaker, ensure that the cir-

cuit breaker is suitable for use with inverter-driven appliances.

Electrical connection checklist

Check that the following requirements are met:

• The electrical wires are protected from high temperature and vi-

brations.

• The current type and power supply voltage connection must cor-

respond to the specifications on the name plate on the pump.

• Use wires at least 14 AWG to supply power to the pump. Follow

all local and NEC wiring codes and practices.

The electrical control panel checklist

NOTICE:

The electrical supply must match the electrical rating of the pump. Im-

proper combination could fail to guarantee protection of the unit.

Check that the following requirements are met:

• The control panel circuit breaker be sized properly to protect the

pump against short-circuit.

• The pump has built in overload and thermal protection, no addi-

tional overload protection is required.

The motor checklist

Electrical supply and grounding wires must be suitable for at least

194°F (90°C).

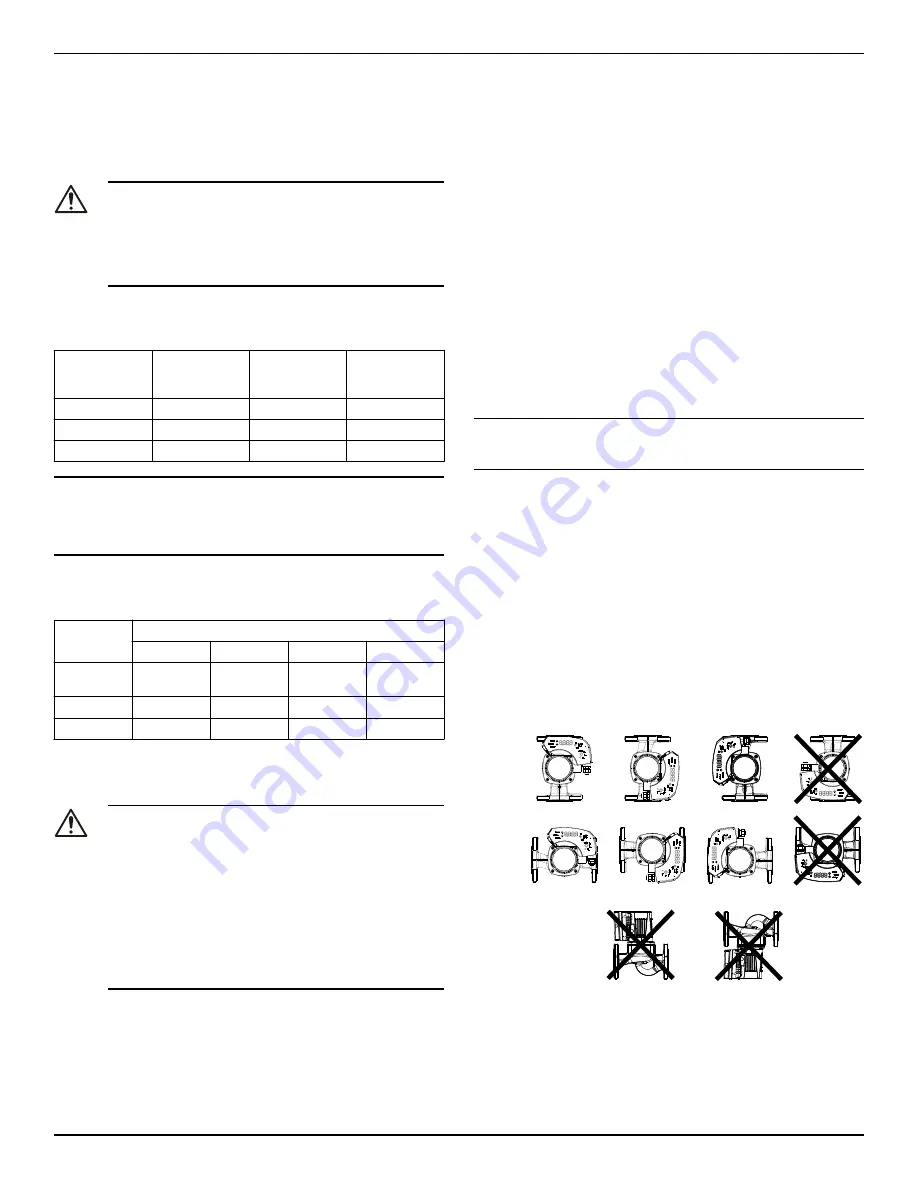

4.5 Pump installation

1.

Install the pump according to the liquid flow direction.

• The arrow on the pump housing shows the flow direction

through the pump body.

• The pump must be installed with the motor in a horizontal

position. For more information about allowed positions, refer

to the following image:

Figure 1: Allowed pump installation

2.

If necessary, rotate the position of the motor for better visibility of

the user interface.

Section 4.6 below describes the procedure of changing of motor

orientation.

3.

If applicable, install the thermal insulation shells.

4 Installation

6

ecocirc XL Installation, Operation, and Maintenance manual