800-543-9038

USA

866-805-7089

CANADA

203-791-8396

LATIN AMERICA / CARIBBEAN

40

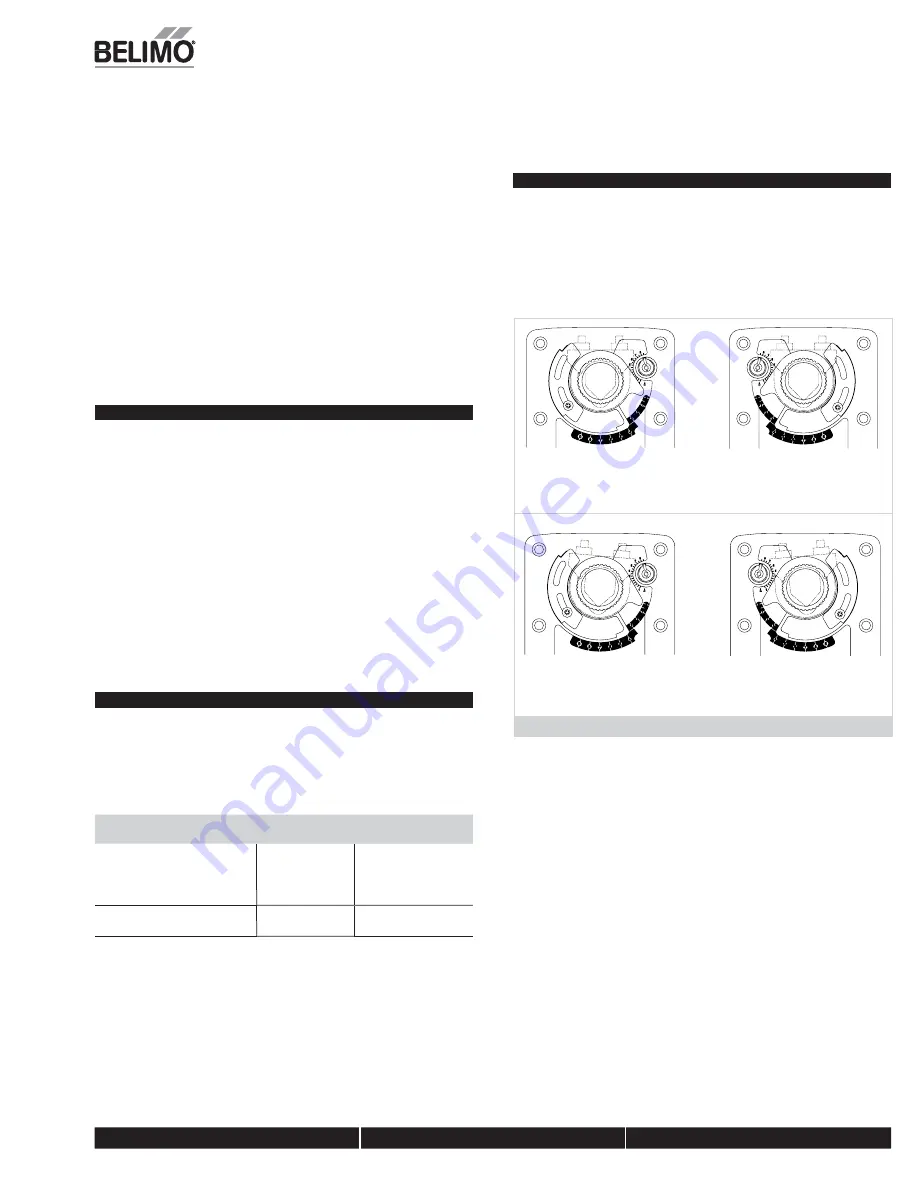

Correct pointer mounting

position if actuator is at

full fail-safe.

Correct pointer mounting

position if actuator is at

5° preload.

Figure A

Installation Instructions

Mechanical Installation

position the clamp so that the pointer section of the tab is pointing to 0° (see

Figure C) and the spline pattern of the clamp mates with spline of the actuator.

Slip the clamp over the spline. (Use the same procedure if the “CW” side is out.)

If your application requires a mechanical minimum position, read the

Rotation

Limiting, Mechanical Minimum Damper Position

section.

n

4. Lock the clamp to the actuator using the retaining clip.

5. Verify that the damper is still in its full fail-safe position.

6. Slide the actuator over the shaft.

7. Position the actuator in the desired location.

8. Tighten the two nuts on the clamp using a 13mm wrench or socket using 11 ft-lb

of torque.

9. Slip the stud of the anti rotation strap into the slot at the base of the actuator.

The stud should be positioned approximately 1/16 of an inch from the closed end

of the slot. Bend the strap as needed to reach the duct. Attach the strap to the

duct with #8 self tapping screws.

Short Shaft Installation

If the shaft extends at least 3/4” from the duct, follow these steps:

1. Determine the best orientation for the universal clamp on the back of the

actuator. The best location would be where you have the easiest access to the V

bolt nuts on the clamp.

2. Engage the clamp to the actuator as close as possible to the determined location.

3. Lock the clamp in place using the remaining retainer clip.

4. Verify that the damper is still in its full fail-safe position.

5. Slide the actuator over the shaft.

6. Position the actuator in the desired location.

7. Tighten the two nuts on the clamp using a 13mm wrench or socket using 11 ft-lb

of torque.

8. Slip the stud of the anti-rotation strap into the slot at the base of the actuator.

The stud should be positioned approximately 1/16 of an inch from the closed end

of the slot. Bend the strap as needed to reach the duct. Attach the strap to the

duct with #8 self tapping screws.

9. If damper position indication is required, use the optional IND-EFB pointer. See

Figure A

.

Jackshaft Installation

The EFB, EFX… series actuator is designed for use with jackshafts up to 1.05” in

diameter. In most applications, the EFB, EFX actuator may be mounted in the same

manner as a standard damper shaft application. If more torque is required than one

EFB, EFX actuator can provide, a second EFB, EFX actuator may be mounted to the

jackshaft.

See wiring guide for wiring details.

EF ACTUATORS WHICH MAY BE USED ON ONE SHAFT

Model

Maximum Quantity

Per Shaft

Minimum Shaft

Diameter

EFB24(-S)(N4)

2*

3/4”

EFX24(-S)(N4)

EFB120(-S)(N4)

EFX120(-S)(N4)

EFB24-MFT(-S)(N4)

3**

3/4” for 2x

1” for 3x

EFX24-MFT(-S)(N4)

* Wired in parellel

** Wired master-slave

MOUNTING:

If the actuators are mounted on the opposed ends of the shaft, the

actuator direction must be selected carefully. Usually, the direction of rotation is

reversed.

Multiple Actuator Mounting

If more torque is required than one EFB, EFX actuator can provide, a second EFB, EFX

actuator may be mounted to the shaft.

NOTE:

The manual positioning mechanism cannot be used in multiple actuator

applications.

Special Wiring and Additional Information: See wiring guide

N40103 - 09/11 - Sub

ject to chan

g

e.

© Belimo

Aircontrols

(USA

), Inc.