800-543-9038

USA

866-805-7089

CANADA

203-791-8396

LATIN AMERICA

35

Installation Instructions

Mechanical Installation

Determining Torque Loading and Actuator Sizing

Damper torque loadings, used in selecting the correct size actuator, should be

provided by the damper manufacturer. If this information is not available, the

following general selection guidelines can be used.

Damper Type

Torque Loading

Opposed blade, without edge seals,

for non-tight close-off applications

3 in-lb/sq. ft.

Parallel blade, without edge seals,

for non-tight close-off applications

4 in-lb/sq. ft.

Opposed blade, with edge seals,

for tight close-off applications

5 in-lb/sq. ft.

Parallel blade, with edge seals,

for tight close-off applications

7 in-lb/sq. ft.

The above torque loadings will work for most applications under 2 in. w.g.

static pressure or 1000 FPM face velocity. For applications between this

criteria and 3 in. w.g. or 2500 FPM, the torque loading should be increased by

a multiplier of 1.5. If the application calls for higher criteria up to 4 in. w.g. or

3000 FPM, use a multiplier of 2.0.

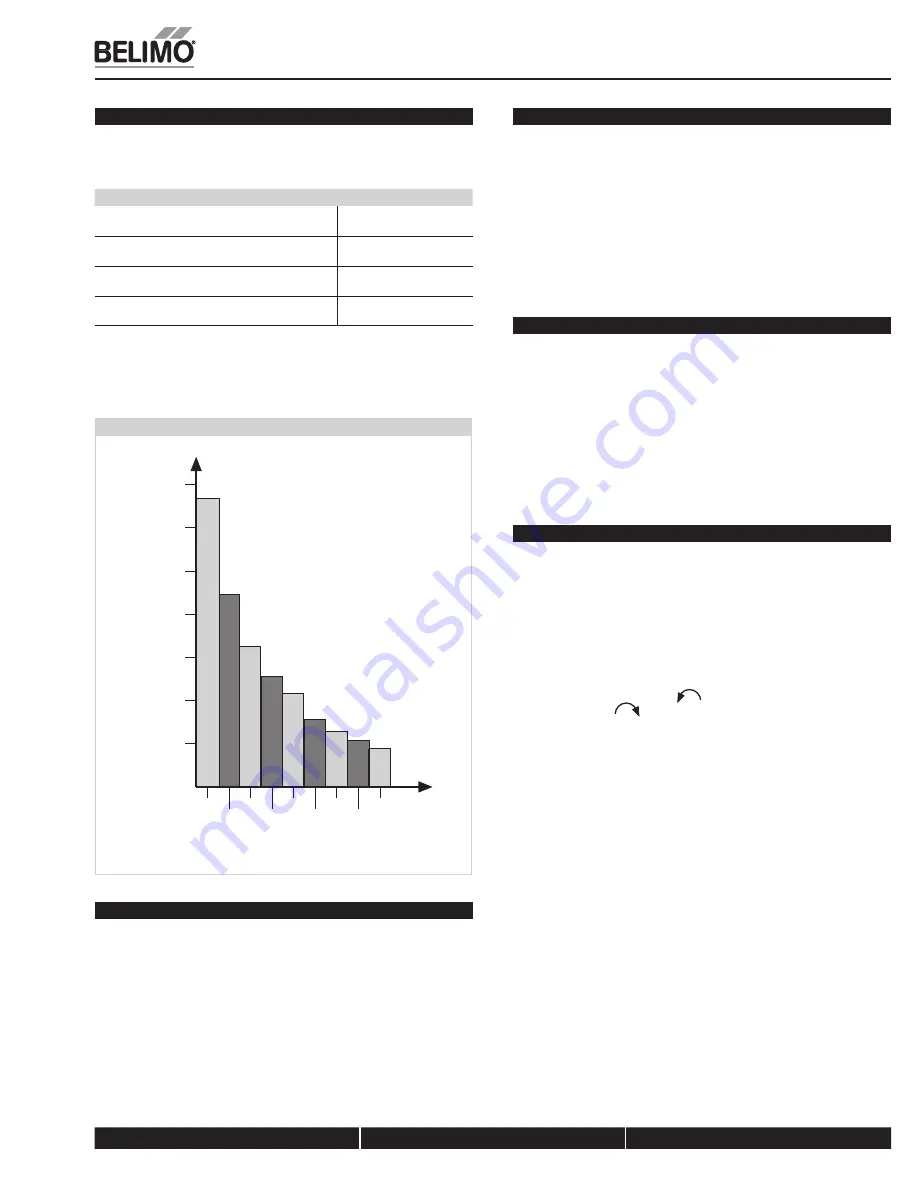

Torque Loading Chart

70

60

50

40

30

20

10

0

2

3

4

6

8

10

5

7

9

Damper Area

(

s

q. ft.)

Torque Loading (in-lb/

s

q. ft.)

General Information

Belimo actuators should be mounted indoors in a dry, relatively clean

environment free from corrosive fumes. If the actuator is to be mounted

outdoors, a protective enclosure must be used to shield the actuator.

For new construction work,

order dampers with extended shafts

. Instruct the

installing contractor to allow space for mounting and service of the Belimo actuator

on the shaft. The damper shaft must extend at least 3 1/2” from the duct. If the

shaft extends less than 3-1/2” or if an obstruction blocks access, the shaft can be

extended with the AV 10-18 shaft extension accessory or the actuator may be

mounted in its short shaft configuration.

Mechanical Operation

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft. The AF series actuators provide true spring return operation for

reliable fail-safe application and positive close-off on air tight dampers. The

spring return system provides constant torque to the damper with, and

without, power applied to the actuator. The AF…-S versions are provided with

2 built-in auxiliary switches. These SPDT switches are provided for safety

interfacing or signaling, for example, for fan start-up. The switching function at

the fail-safe position is fixed at +5°, the other switch function is adjustable

b25 to +85°.

Automatic Airtight Dampers/Manual Override

The AF series provides 95° of rotation and is provided with a graduated

position indicator showing 0° to 95°.

The AF has a unique manual positioning mechanism which allows the setting

of any damper position within its 95° of rotation. A pre-tensioned spring

automatically tightens damper when power is applied to the actuator,

compensating for damper seal deterioration.

The actuator is shipped at +5° (5° from full fail-safe) to provide automatic

compression against damper gaskets for tight shut-off. When power is applied,

the manual mechanism is released and the actuator drives toward the full fail-

safe position.

Standard Mounting

NOTE: The AF…series actuator is shipped with the manual override

adjusted for a +5° position at the universal clamp (not at full fail-safe, 0°).

This allows for automatic compression of damper blade seals when the

actuator is in use, providing tight shut-off. This assumes that the damper is

to have tight shut-off at the fail-safe position. If tight close-off is desired at

the opposite direction from fail-safe, the manual override should be

released so the actuator can go to the full fail-safe position. See the manual

override instructions.

1. Manually move the damper to the fail-safe position (usually closed). If the

shaft rotated counterclockwise (

), this is a CCW installation. If the shaft

rotated clockwise (

), this is a CW installation. In a CCW installation, the

actuator side marked “CCW” faces out, while in a CW installation, the side

marked “CW” faces out. All other steps are identical.

2. The actuator is usually shipped with the universal clamp mounted to the

“CCW” side of the actuator. To test for adequate shaft length, slide the

actuator over the shaft with the side marked “CCW” (or the “CW” side if this

is the side with the clamp). If the shaft extends at least 1/8” through the

clamp, mount the actuator as follows. If not, go to the

Short Shaft

Installation

section.

3. If the clamp is not on the correct side as determined in step #1, re-mount the

clamp as follows. If it is on the correct side, proceed to step #5. Look at the

universal clamp. If you are mounting the actuator with the “CCW” side out,

position the clamp so that the pointer section of the tab is pointing to 0° (see

Figure C

) and the spline pattern of the clamp mates with spline of the

actuator. Slip the clamp over the spline. (Use the same procedure if the “CW”

side is out.) If your application requires a mechanical minimum position, read

the

Rotation Limiting, Mechanical Minimum Damper Position

section.

4. Lock the clamp to the actuator using the retaining clip.

5. Verify that the damper is still in its full fail-safe position.

6. Slide the actuator over the shaft.

7. Position the actuator in the desired location.

8. Tighten the two nuts on the clamp using a 10mm wrench or socket using

6-8 ft-lb of torque.

9. Slip the stud of the anti rotation strap into the slot at the base of the

actuator. The stud should be positioned approximately 1/16 of an inch from

the closed end of the slot. Bend the strap as needed to reach the duct.

Attach the strap to the duct with #8 self tapping screws.

K20901 - 01/09 - Subject to change. © Belimo Air

controls (USA), Inc.