DURABLASTER

®

WHEEL CLEANER

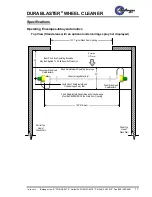

8

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL054

Introduction

The

DuraBlaster®

is a component with two options. One option is a rotating version that requires

tire sensing. The second option is a fixed (non-rotating) version that operates with or without tire

sensing. Both options can be programmed to operate during any wash package to provide extra

attention on the vehicle wheels. The driver-side and passenger-side

DuraBlasters®

, each have

two, 4 nozzle spinners to spray up to 1000 psi water on each wheel. The nozzle pressure and

water volume of the

DuraBlaster®

is dependant on the capability of the optional pump station.

Rotating DuraBlaster®

The rotating

DuraBlaster®

operation is initiated by a programmed output from the main system

controller. A PLC inside the system control panel turns on the pump station. A 2-position air

solenoid valve provides air to a cylinder that holds the spray assemblies rotated to the start

position toward the entrance of the tunnel. High pressure water sprays the front bumper and along

the lower rocker panels. A tire sensing device triggers an input to the PLC in a system with a tire

sensing controller or starts a timer in the component control box. Then, the air solenoid shifts,

causing the

DuraBlaster®

to rotate with the wheel, for maximum cleaning time. After full stroke,

the PLC or timer will shift the valve and the

DuraBlaster®

will rotate toward the entrance again.

The cycle will repeat on the rear wheel after it is sensed. Belanger® sells two types of tire sensing

devices. They are the bell hose actuator and a tire photo-eye sensing kit. Once the rear tire

application is complete the system controller will shut off the

DuraBlaster®

function, and the

spray assemblies will sit in a rest position rotated toward the entrance of the tunnel.

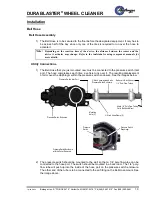

The rotating

DuraBlaster®

for tunnel applications utilizes a vertical cylinder that when stroked,

rotates a piston that is attached to the spinner manifold assembly. The return speed is set by an

air flow control under the back cover, using a small screw driver. This speed should be quick

enough to return and be ready for the rear wheel, yet not causing any hard slamming of the

equipment. The tracking speed is set by turning a flow control knob protruding out of the back

cover. This should be readjusted whenever conveyor speed is changed.

Fixed DuraBlaster®

The fixed

DuraBlaster®

operation can also be initiated by a programmed output from the main

system controller or as a timed programmed function. High pressure water sprays the front

bumper and along the lower rocker panels.

Since there is no rotating cylinder, no air is required. Other than the rotating action, the function of

the fixed

DuraBlaster®

is the same as the function of the rotating

DuraBlaster®.

So, it can be

used in similar applications.

If it is actuated as a timed function, the fixed

DuraBlaster®

can be used as an alternative to the

Belanger® Rocker Spin Clean.

Note:

Uncrate and inspect shipment for damage, and to verify that all pieces are there. If there is

any damaged equipment, file a claim with the trucking company immediately. Receiving

party is responsible for filing claim with trucking company. Notify your local distributor or

Belanger, Inc.® immediately if shipment is determined damaged or incomplete.

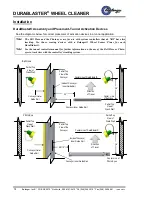

Rotating

DuraBlaster®

Fixed

DuraBlaster®