Operating

Instructions

Start the tractor and set at idle RPM. With the Tiller lifted

off the ground, engage PTO and slowly advance throttle

to 540 RPM.

NOTE: Rotary Tiller is designed to run at

540 RPM ONLY.

Select a low gear on the tractor and begin to move

forward. Tractor ground speed is to be controlled by

gear selection

ONLY

and not engine speed.

Travelling

at a fast ground speed while using the Tiller could

damage the unit.

As the tractor moves forward, slowly

lower the Tiller down. Allow the tiller tines to gradually

engage the ground.

The Tiller is designed to be operated in a forward

direction

ONLY

. Running in reverse could damage the

Tiller and the tractor and void the Tiller warranty.

Adjust the back plate with regulating chain until the

desired mulching effect is achieved.

NOTE: NEVER

ATTEMPT TO ADJUST THE ROTARY TILLER WHILE

THE TRACTOR IS RUNNING.

Do NOT allow the tractor to engine or Tiller to bog

down or stall. This causes undue wear and tear on

the Tiller and the tractor. If this continues to happen,

reduce ground speed and raise tilling depth of Tiller.

Never attempt to remove objects from the rotary bar

until the tractor has been shut down and the Tiller

tines have completely stopped.

Never attempt to turn the tractor or travel in reverse

with the PTO engaged and the Tiller in the ground.

Always raise the Tiller out of the ground when

backing up or attempting to turn. Failure to do so

may cause damage to the Tiller.

Never attempt to operate the Tiller on sudden steep

inclines or declines with the PTO engaged. ALWAYS

raise the Tiller out of the ground when traveling over

sudden inclines or declines. Failure to do so may

cause damage to the Tiller.

Transport Safety

• Always comply with all state and local laws

governing highway safety and movement of farm

machinery on public roads.

• The use of flashing amber lights is acceptable in

most localities. However, some localities prohibit

their use. Local laws should be checked for all

lighting and marking requirements. Always use

proper lighting and a Slow Moving Vehicle (SMV)

sign when on a highway or road. Do NOT exceed 20

mph. Reduce speed on rough roads.

• Plan your route to avoid heavy traffic.

• Always yield to oncoming traffic at narrow bridges,

intersections, etc. Watch for traffic when operating

near or crossing roadways.

• Take hills and curves only at a low speed and at a

gradual angle. Make certain that at least 20% of the

tractor’s weight in the front wheels to maintain safe

steering. Slow down on rough or uneven surfaces.

Check the tractor’s manual for proper use on slopes.

• Use extreme care and maintain minimum ground

contact when operating close to ditches or fences.

Be careful when turning sharp corners.

Maintenance

1) Periodically check and maintain proper gear oil levels

in both top and side gearboxes. Check the vent plugs of

both gearboxes and make sure they are clean and free

of dirt or debris to ensure proper airflow.

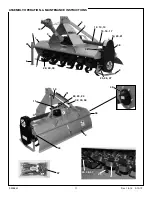

2) Every 8 hours, grease “out board” hub (below left),

PTO shaft universal joints (below right), PTO shaft

safety shield, and PTO telescoping surface.

Use ONLY

grade Type ll tube grease. NOTE: Do NOT grease

the slip clutch assembly

.

3) Before each use, check to make sure all safety

shields are installed and working properly.

4) After each use clean the debris from the Tiller tines.

Inspect for any damaged or worn parts and replace

before next use.

5) Periodically check all nuts and bolts to insure they

are tight and secure.

6) Periodically loosen torque spring bolts and allow

WARNING

Grease fitting

Grease

(2) fittings

here

ASSEMBLY, OPERATION, & MAINTENANCE INSTRUCTIONS

F-20982-1

8

Rev. 4-27-12 2-10-12