11

TECHNICAL SPECIFICATIONS

Specifications are subject to changes without prior notice.

All values measured in specific conditions.

Technology:

Detection mode:

Max. detection range:

Remission factor:

Angular resolution:

Min. detected object size (typ.):

(in proportion to object distance)

Testbody:

Emission characteristics:

IR laser:

Red visible laser:

Supply voltage:

Power consumption:

Peak current at power-on:

Cable length:

Response time:

Output:

Max. switching voltage:

Max. switching current:

Switching time:

Output resistance:

Voltage drop on output:

Leakage current:

Input:

Max. contact voltage:

Voltage threshold:

Response time monitoring input:

LED-signal:

Dimensions:

Material:

Colour:

Mounting angles on bracket:

Rotation angles on bracket:

Tilt angles on bracket:

Protection degree:

Temperature range:

Humidity:

Vibrations:

Pollution on front screens:

Expected lifetime:

Norm conformity:

laser scanner, time-of-flight measurement

motion and presence (EN 12453 Typ. E)

LZR

®

-I100: 9.9 m x 9.9 m; LZR

®

-I110: 5.0 m x 5.0 m

> 2 %

0,3516 °

LZR

®

-I100: 2,1 cm @ 3 m ; 3,5 cm @ 5 m ; 7 cm @ 10 m

LZR

®

-I110: 2,1 cm @ 3 m ; 3,5 cm @ 5 m

700 mm x 300 mm x 200 mm (testbody A according to EN 12445)

wavelength 905 nm; max. output pulse power 75 W (CLASS 1)

wavelength 650 nm; max. output CW power 3 mW (CLASS 3R)

10-35 V DC @ sensor side

< 5 W

1.8 A (max. 80 ms @ 35 V)

10 m

typ. 20 ms; max. 80 ms

2 electronic relays (galvanic isolated - polarity free)

35 V DC / 24 V AC

80 mA (resistive)

t

ON

=5 ms; t

OFF

=5 ms

typ 30 Ω

< 0.7 V @ 20 mA

< 10 µA

2 optocouplers (galvanic isolated - polarity free)

30 V DC (over-voltage protected)

Log. H: >8 V DC; Log. L: <3 V DC

< 5 ms

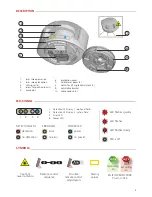

1 blue LED: power-on status

1 orange LED: error status

2 bi-coloured LEDs: detection/output status

(green: no detection; red: detection)

125 mm (D) x 93 mm (W) x 70 mm (H) (mounting b 14 mm)

PC/ASA

black or white

-45 °, 0 °, 45 °

-5 ° to +5 ° (lockable)

-3 ° to +3 °

IP65

-30 °C to +60 °C if powered; -10 °C to +60 °C unpowered

0-95 % non-condensing

< 2 G

max. 30 %; homogenous

8 years

2006/95/EC: LVD; 2002/95/EC: RoHS; 2004/108/EC: EMC; 2006/42/EC: MD;

EN 12453:2000 chapter 5.1.1.6, chapter 5.5.1 Safety device E;

EN 12978:2009; EN ISO 13849-1:2008 Pl “d”/ CAT2;

EN 60529:2001; IEC 60825-1:2007; EN 60950-1:2005;

EN 61000-6-2:2005; EN 61000-6-3:2006;

IEC 61496-1:2009; EN 61496-3:2008 ESPE Type 2;

EN 62061:2005 SIL 2; DIN 18650-1:2010 Chapter 5.7.4