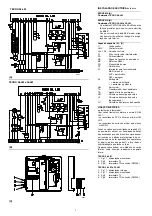

(A)

(B)

(C)

TECNO 28-LM

TECNO 38-LM and 50-LM

D862

D863

D864

7

ELECTRICAL SYSTEM

as set up by the

manufacturer

LAYOUT (A)

Burner TECNO 28-LM

LAYOUT (B)

Burners TECNO 38-LM and 50-LM

•

Models TECNO 38-LM and 50-LM leave the

factory preset for

400 V

power supply.

• If

230 V

power supply is used, change the

motor connection from star to delta and

change the setting of the thermal cut-out as

well.

Key to Layout (A) - (B)

C

- Capacitor

CMV

- Motor contactor

LAL 1.25 - Control box

F1

- Protection against radio interference

FR

- Photocell

MB

- Terminal strip

MV

- Fan motor

PO

- Oil pressure switch

RT

- Thermal cut-out

S1

- Switch for following operations :

MAN = manual

AUT = automatic

OFF

S2

- Button for :

-

= power reduction

+ = power increase

SM

- Servomotor

TA

- Ignition transformer

TB

- Burner ground (earth) connection

VM

- Delivery pump valve

VS

- Delivery pump valve (safety valve)

VU

- Valve on nozzle return

ELECTRICAL CONNECTIONS

set by installer

Use flexible cables according to regulation EN

60 335-1:

• if in PVC boot, use at least H05 VV-F

• if in rubber boot, use at least H05 RR-F.

All the cables to be connected to the burner ter-

minal strip 5)(C) must be routed through the fair-

leads, supplied by the manufacturer for insertion

into the holes in the plate, preferably those on the

left side, after having unscrewed screws 6), split

the plate into its two parts 7) and 8) then re-

moved the thin diaphragm effectively closing the

aperture.

The fair leads and precut holes can be used in

various ways. One example is given below:

TECNO 28-LM

1 - Pg 11 Single-phase power supply

3 - Pg 9

Control device TL

4 - Pg 9

Control device TR or probe (RWF40)

TECNO 38-LM and 50-LM

1 - Pg 11 Three-phase power supply

2 - Pg 11 Single-phase power supply

3 - Pg 9

Control device TL

4 - Pg 9

Control device TR or probe (RWF40)