TAM 00609

12

DA 100

– 280

03 / 2015

Three phase asynchronous motor air cooled

Englisch

Vibrations:

The vibration behavior of the system, which is determined by the output elements, the mounting

conditions, the alignment, the installation and the effects of external vibrations, may cause the vibra-

tion values at the motor to increase.

In the interest of reliable motor operation and a long bearing service life, the permitted vibration

values in accordance with EN 60034-14 are not supposed to be exceeded. Under certain circum-

stances, the rotor may need to be fully balanced with the output element (in accordance with ISO

1940).

The simulated vibration values after assembly must not exceed the permitted rates of acceleration

(refer to

chapter 2.4

)

If there are deviations from normal operation

– such as rise in temperature, noises, vibrations –

disable the motor in case of doubt. Identify the cause and contact the manufacturer, if necessary,

3

Mounting

Safety instructions

3.1

Prior to mounting:

Never mount or commission a damaged electric motor.

Never install the electric motor in a damaged machine.

Before mounting the electric motor, make sure that it is suitable for your machine.

During the mounting:

Only mount the motor on the fixing options provided.

The motor should not be exposed to knocks such as with a hammer, or shocks when mounting.

Make sure that all covers and safety devices are mounted. All safety devices must comply with the

latest regulations (refer to EN 60204).

Air cooling:

Protective covers must be attached to the air inlet and outlet openings where there is a possibility

during operation of foreign matter falling into the fan.

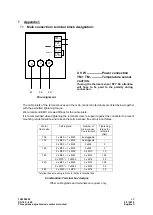

Installation, fixing

3.2

Prior to and during mounting, check the following:

•

The motor is not damaged (e.g. the shaft sealing ring should not be damaged in any way by sharp ob-

jects).

•

The motor is not mounted in the danger zone of other facilities.

•

The motor is used for the intended purpose.

(observe type plate details, warning labels and signs.)

•

Anti-corrosive agents are fully removed from the shaft ends.

When using standard solvents such as acetone or benzine, the shaft sealing ring must not be moistened!

•

The motor is designed for the ambient conditions and environmental influences on site.

•

The space in the machine is suitable for the cooling method employed by the electric motor.

The motor must be installed in such a way that the coolant lines can subsequently be connected.

•

The motor can be mounted and operated with the connection data and fixing possibilities provided.

The mounting dimensions of the motor and the tolerance details are provided in the technical documen-

tation.

When mounting the flanges on the motor, make sure that the flange surface rests well and evenly. The

supports and bearing surface must be clean and undamaged. They must be precisely aligned with the

connecting shafts to prevent the bearing, shafts and housing being exposed to damaging loads through