by

B A T H O L O G Y

8

Fan Installation

A t m o s p h e r i c 320

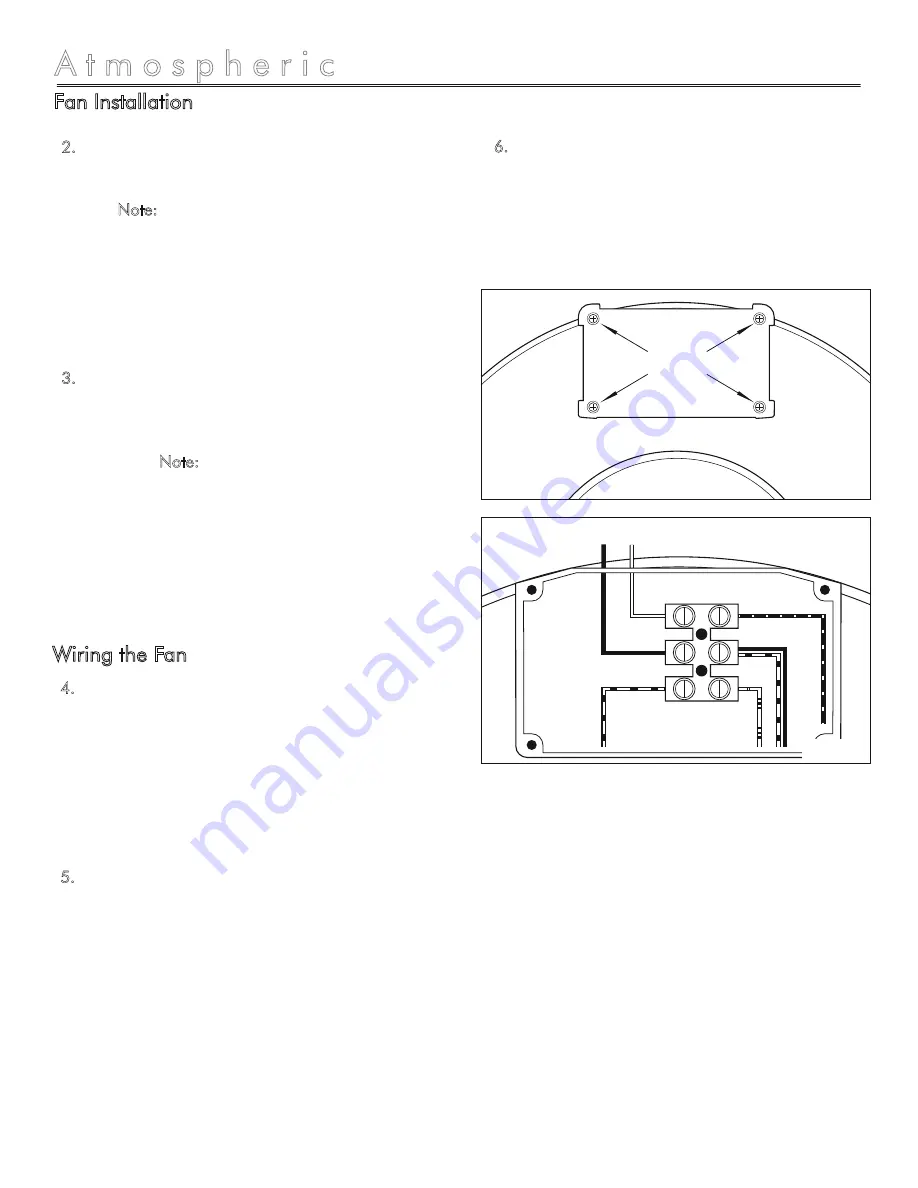

Remove the screws securing the terminal box

cover plate located on the side of the fan (1)

(

see figure 3

). All fan motor connections are

pre-wired to an electrical terminal strip. A 3/8”

romex type cable restraint connector will be

needed to secure the wiring through the

knockout provided on the side of the terminal

box.

Bring incoming electrical service through the

romex connector and the fan knockout. Be

sure to place the connector nut over the wiring

coming into the terminal box. There are two

open ports on the terminal strip. Using a small

regular screwdriver, tighten the neutral (white)

wire of the incoming supply under the open

terminal strip port labeled “N”. Tighten the line

(black) wire of the incoming supply under the

open terminal strip port labeled “L”. Since the

fan motor is isolated within a plastic housing,

grounding is not necessary (

see figure 4

).

4.

5.

Secure the romex connector. Secure the

incoming supply with the romex connector.

Replace the fan terminal box cover. All fan

motor and capacitor connections have been

pre-wired from the factory. No additional fan

wiring is necessary.

6.

Using the 1” wood screws (4) provided, attach

the fan mounting bracket (2) to a support beam

at the selected location (

see figure 1 on page

6

). Note: Fan (1) mounting can be at any

point along the duct and in any angle;

however, vertical mounting is recommended to

reduce condensation buildup in the fan (1). If a

horizontal installation is necessary and

condensation buildup may pose a problem,

wrap insulation around the fan (1).

Attach fan (1) to the mounting bracket (2) with

the three 7/16" sheet metal screws (5)

provided, making sure the wiring box is

positioned for easy access (

see figure 2 on

page 6

). Note: Bracket (2) is provided with

rubber vibration isolation grommets (3) to

prevent the transmission of sound through the

structure. Be careful not to overtighten. Also,

care should be taken not to strip the

plastic

housing

. Screws (5) are selftapping and do not

require pilot holes. However, pilot holes no

larger than 3/32" are recommended.

2.

3.

Wiring the Fan

Screws

N

L

Figure 4

Figure 3

Black

White

Blue

Brown

Black / Red

Red

Supply from Electronic Timer Control / Slide Speed Control