Cleaning and Descaling

32 / 40

190160

EN

1. Clean the brewing group and the holder only with a special powder for cleaning

pressure coffee machines. Observe instructions of such a cleaning agent's

manufacturer.

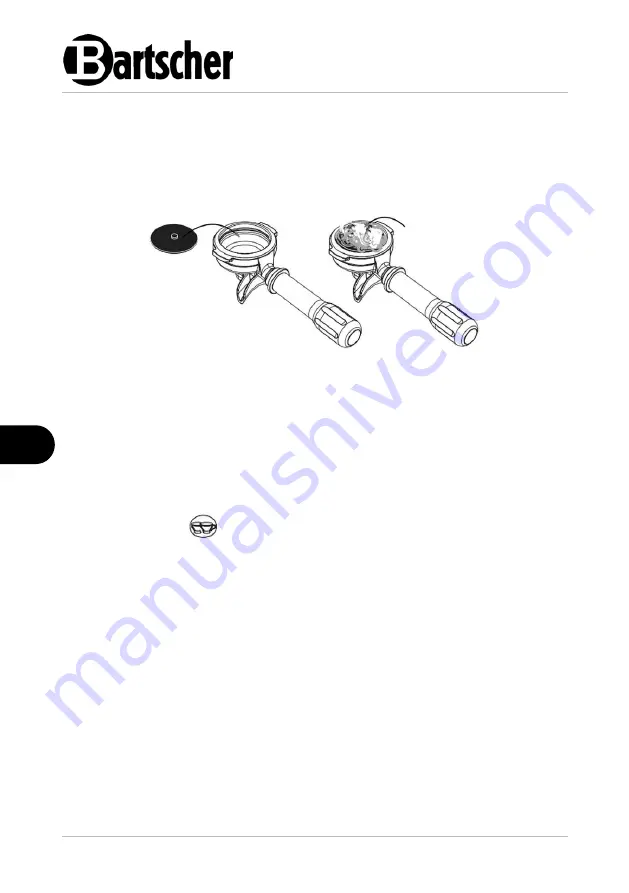

2. Rotate the handle out and remove it out of the brewing group.

Filter membrane

Special cleaning agent for cleaning

pressure coffee machines.

Fig. 22

3. Insert the filter membrane into the holder filter.

4. Pour the special powder for cleaning pressure coffee machines into the holder

filter.

5. Insert the holder in the brewing group head and engage it.

6. Activate automatic cleaning:

– Switch the coffee machine off.

– Press the

button briefly on the control panel of the brewing group

that is to be cleaned.

– Switch the appliance on with the button pressed. The automatic cleaning

starts.

– Release the button.