page 74

page 74

page 74

page 74

page 74

475 A CRL

800-00167

S10A SWING MOTOR GEARBOX MAINTENANCE CONTINUED...

Checking Rolling Torque

Checking Rolling Torque

Checking Rolling Torque

Checking Rolling Torque

Checking Rolling Torque

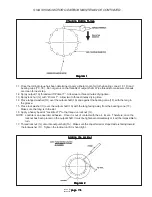

Diagram 1

Diagram 1

Diagram 1

Diagram 1

Diagram 1

Staking the Locknut

Staking the Locknut

Staking the Locknut

Staking the Locknut

Staking the Locknut

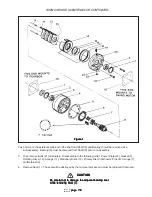

Diagram 2

Diagram 2

Diagram 2

Diagram 2

Diagram 2

11. Once the rolling torque has been determined, apply a liberal coat of oil to the bearing cones (1F, 1D) and

bearing cups (1C, 1E). Do not get oil on the threads of output shaft. Wipe threads to make sure threads

are clean for next step.

12. Spray output (1A) threads with “Primer T”. Allow two to three minutes drying time.

13. Spray lock nut (1J) with “Primer T”. Allow two to three minutes drying time.

14. Place tanged washer (1H) over the output shaft (1A) and against the bearing cone (1F), with the tang in

the groove.

15. Place lock washer (1I) over the output shaft (1A) with the tang facing away from the bearing cone (1F).

Make sure the tang is in the slot.

16. Apply a heavy bead of "Locktite 277" to the thread on locknut (1J).

NOTE: Locktite is an anaerobic adhesive. Once it is out of contact with the air, it sets. Therefore, once the

locknut has been placed on the output shaft, it must be tightened immediately or it will be impossible to

turn.

17. Thread locknut (1J) onto thte output shaft (1A). Make sure the chamferred or sloped side is facing toward

the lockwasher (1I). Tighten the locknut until it is hand tight.