Manual 2100-489

Page

4 of 26

WALL MOUNT GENERAL INFORMATION

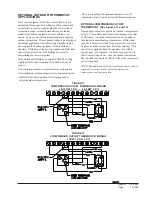

HEAT PUMP WALL MOUNT MODEL NOMENCLATURE

WH

36

3

A

10

X

X

X

X

X

A

VOLTS & PHASE

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

MODEL NUMBER

REVISIONS

CAPACITY

30 - 2

½

Ton

36 - 3 Ton

KW

VENTILATION OPTIONS

X - Barometric Fresh Air Damper (Standard)

B - Blank-off Plate

M - Motorized Fresh Air Damper

V - Commercial Room Ventilator - Motorized with Exhaust

E - Economizer (Internal - Fully Modulating with Exhaust

R - Energy Recovery Ventilator - with Exhaust

FILTER OPTIONS

X - 1-Inch Throwaway (Standard)

W - 1-Inch Washable

P - 2-Inch Pleated

COLOR OPTIONS

X - Beige (Standard)

1 - White

2 - Mesa Brown

4 - Buckeye Gray

5 - Desert Brown

8 - Dark Bronze

CONTROL

MODULES

COIL OPTIONS

X - Standard

1 - Phenolic Coated Evaporator

2 - Phenolic Coated Condenser

3 - Phenolic Coated Evaporator

and Condenser

OUTLET OPTIONS

X - Front (Standard)

T - Top on WH30 and WH36

Models

NOTE: For 0 KW and circuit breakers (230/208 Volt) or pull disconnects (460 Volt) applications, insert 0Z in the KW field of model number.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked

for external signs of shipping damage. If damage is

found, the receiving party must contact the last carrier

immediately, preferably in writing, requesting inspection

by the carrier’s agent.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

heat pump system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and

standards.

Size of unit for a proposed installation should be based

on heat loss calculations made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association for

the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No. 90A,

and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

DUCT WORK

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work, supply and return,

must be properly sized for the design airflow

requirement of the equipment. Air Conditioning

Contractors of America (ACCA) is an excellent guide to

proper sizing. All duct work or portions thereof not in

the conditioned space should be properly insulated in

order to both conserve energy and prevent condensation

or moisture damage.