Manual 2100-495A

Page

16 of 21

All units are factory set on High speed and can be field

adjusted for lower speeds if required.

240-Volt Units (Single switch models):

The speed of

both blowers (intake and exhaust) can be controlled by a

switch located on the left side of the control panel,

behind the WFERV front door.

240-Volt Units (Dual switch models):

The speed of

each blower (intake and exhaust) can be controlled

independently by two (2) switches located on the left side

of the control panel, behind the WFERV front door. The

switch located on the upper part of the control panel

controls the intake blower located in the upper assembly.

The switch located on the lower part of the control panel

controls the exhaust blower located in the lower

assembly. See Figure 6

.

If desired, the intake blower can be set up for one speed

and the exhaust blower set up for another speed if needed

for the specific application.

TABLE 1

VENTILATION AIR (CFM)

)

M

F

C

(

R

I

A

N

O

I

T

A

L

I

T

N

E

V

l

e

d

o

M

d

e

e

p

S

h

g

i

H

)

k

c

a

l

B

(

d

e

e

p

S

.

d

e

M

)

e

u

l

B

(

d

e

e

p

S

w

o

L

)

d

e

R

(

V

R

E

F

W

0

5

4

0

7

3

0

8

2

ENERGY RECOVERY VENTILATOR

MAINTENANCE

GENERAL INFORMATION

The ability to clean exposed surfaces within air moving

systems is an important design consideration for the

maintenance of system performance and air quality. The

need for periodic cleaning will be a function of operating

schedule, climate, and contaminants in the indoor air

being exhausted and in the outdoor air being supplied to

the building. All components exposed to the airstream,

including energy recovery wheels, may require cleaning

in most applications.

Rotary counterflow heat exchanges (heat wheels) with

laminar airflow are “self-cleaning” with respect to dry

particles. Smaller particles pass through; larger particles

land on the surface and are blown clear as the flow

direction is reversed. For this reason, the primary need

for cleaning is to remove films of oil-based aerosols that

have condensed on energy transfer surfaces. Buildup of

material over time may eventually reduce airflow. Most

importantly, in the case of desiccant coated (enthalpy)

wheels, such films can close off micron sized pores at the

surface of the desiccant material, reducing the efficiency

with which the desiccant can absorb and desorb moisture.

FREQUENCY

In a reasonably clean indoor environment such as a

school, office building, or home, experience shows that

reductions of airflow or loss of sensible (temperature)

effectiveness may not occur for ten or more years.

However, experience also shows that measurable changes

in latent energy (water vapor) transfer can occur in

shorter periods of time in commercial, institutional and

residential applications experiencing moderate occupant

smoking or with cooking facilities. In applications

experiencing unusually high levels of occupant smoking,

such as smoking lounges, nightclubs, bars and

restaurants, washing of energy transfer surfaces, as

frequently as every six months, may be necessary to

maintain latent transfer efficiency. Similar washing

cycles may also be appropriate for industrial applications

involving the ventilation of high levels of smoke or oil-

based aerosols such as those found in welding or

machining operations, for example. In these applications,

latent efficiency losses of as much as 40% or more may

develop over a period of one to three years.

CLEANABILITY AND PERFORMANCE

In order to maintain energy recovery ventilation systems,

energy transfer surfaces must be accessible for washing to

remove oils, grease, tars and dirt that can impede

performance or generate odors. Washing of the desiccant

surfaces is required to remove contaminate buildups that

can reduce adsorption of water molecules. The continued

ability of an enthalpy wheel to transfer latent energy

depends upon the permanence of the bond between the

desiccant and the energy transfer surfaces.

Bard wheels feature silica gel desiccant permanently

bonded to the heat exchange surface without adhesives;

the desiccant will not be lost in the washing process.

Proper cleaning of the Bard energy recovery wheel will

restore latent effectiveness to near original performance.

MAINTENANCE PROCEDURES

NOTE: Local conditions can vary and affect the

required time between routine maintenance

procedures, therefore all sites (or specific units

at a site) may not have the same schedule to

maintain acceptable performance. The

following timetables are recommended and can

be altered based on local experience.

WARNING

Open circuit breaker to shut all power OFF

before doing this. Failure to do so could

result in injury or death due to electrical

shock.

Summary of Contents for WFERV-A-X

Page 10: ...Manual 2100 495A Page 10 of 21 FIGURE 5 INSTALLATION OF WFERV...

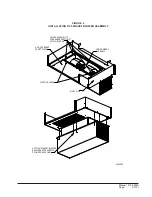

Page 11: ...Manual 2100 495A Page 11 of 21 FIGURE 6 WFERV ASSEMBLY...

Page 13: ...Manual 2100 495A Page 13 of 21 FIGURE 8 INSTALLATION OF FRESH AIR INTAKE HOOD ASSEMBLY...

Page 18: ...Manual 2100 495A Page 18 of 21 FIGURE 10 THERMOSTAT WIRING DIAGRAM...

Page 19: ...Manual 2100 495A Page 19 of 21 FIGURE 11 TERMINAL BLOCK LOCATION...

Page 20: ...Manual 2100 495A Page 20 of 21 FIGURE 12 HUB ASSEMBLY WITH BALL BEARING...

Page 21: ...Manual 2100 495A Page 21 of 21...