R5906848 /04

DP2K SLP Series

187

3

3

4

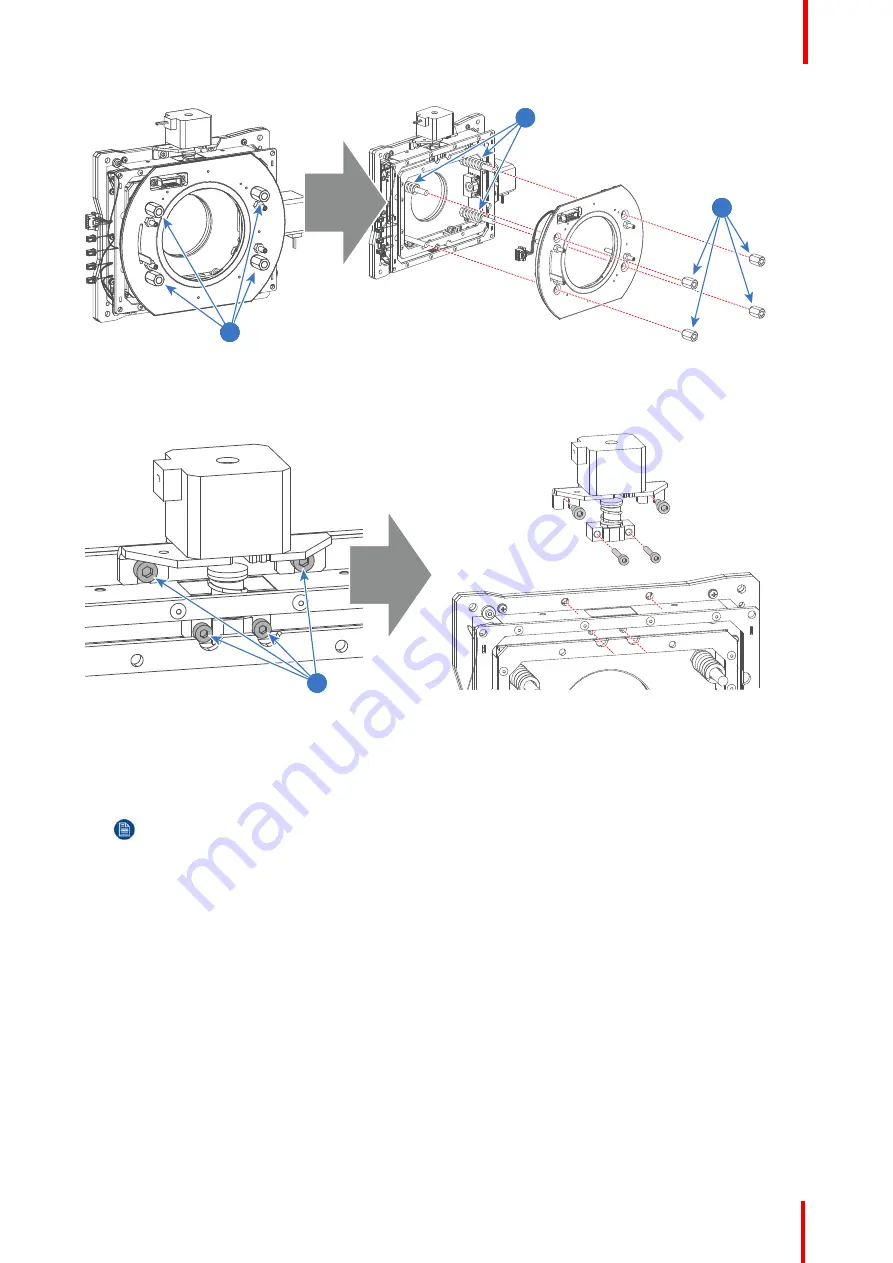

Image 16-27

2.

Remove the Vertical Shift stepper motor from the assembly by loosing the four screws (reference 5 Image 16-

28) as indicated. Use a 3mm and 4mm Allen wrench.

5

Image 16-28

3.

Remove the big bracket (reference 6 Image 16-29) and the small bracket (reference 8 Image 16-29) from the

old stepper motor and install these parts on the new stepper motor as illustrated. Use a T10 Torx driver for the

four screws (reference 7 Image 16-29) and a 10mm open end wrench for the small bracket (reference 9

Image 16-29).

Note:

The big bracket (reference 6 Image 16-29) used with the Vertical Shift stepper motor has two

cuts (reference 10 Image 16-29).

Summary of Contents for DP2K SLP Series

Page 1: ...ENABLING BRIGHT OUTCOMES Service Manual DP2K SLP Series ...

Page 4: ......

Page 10: ...R5906848 04 DP2K SLP Series 10 ...

Page 14: ...R5906848 04 DP2K SLP Series 14 Safety ...

Page 24: ...R5906848 04 DP2K SLP Series 24 General ...

Page 30: ...R5906848 04 DP2K SLP Series 30 Preventative maintenance actions ...

Page 38: ...R5906848 04 DP2K SLP Series 38 Mains Input ...

Page 90: ...R5906848 04 DP2K SLP Series 90 Laser Phosphor Light Source ...

Page 94: ...R5906848 04 DP2K SLP Series 94 10 Reinstall all covers Liquid cooling circuit ...

Page 138: ...R5906848 04 DP2K SLP Series 138 Light Pipe ...

Page 147: ...147 R5906848 04 DP2K SLP Series Optical alignment 12 ...

Page 150: ...R5906848 04 DP2K SLP Series 150 Optical alignment ...

Page 248: ...R5906848 04 DP2K SLP Series 248 Card Cage ...

Page 263: ...263 R5906848 04 DP2K SLP Series Exhaust system 20 ...

Page 265: ...265 R5906848 04 DP2K SLP Series Board Diagnostic LED s 21 ...

Page 270: ...R5906848 04 DP2K SLP Series 270 Board Diagnostic LED s ...

Page 290: ...R5906848 04 DP2K SLP Series 290 Dust Filters ...

Page 294: ...R5906848 04 DP2K SLP Series 294 Troubleshooting ...

Page 382: ...R5906848 04 DP2K SLP Series 382 Troubleshooting ...

Page 394: ...R5906848 04 DP2K SLP Series 394 Projector cleaning ...

Page 395: ...395 Overview Hazards R5906848 04 DP2K SLP Series Appendix A ...

Page 409: ...R5906848 04 DP2K SLP Series 409 ...