18

BlendPRO-II • User’s Guide

2. Hardware Orientation

BlendPRO-II Rear Panel

3) Serial

Port

One 9-pin D connector is provided for RS-232 serial communications with

BlendPRO-II, typically for diagnostic purposes. The port is configured as a DCE,

115K Baud, 8 data bit, 1 stop bit, and no parity bits. The port can be connected to

a standard PC serial port with a straight through DB-9 to DB-9 cable.

In Appendix A, refer to the “

Serial Connector

” section on page 40 for pinouts.

4) AC

Connector

One

AC Connector

is provided for connecting BlendPRO-II to your facility’s AC

power source. The integral switch turns the chassis on and off.

5) Inputs

Section

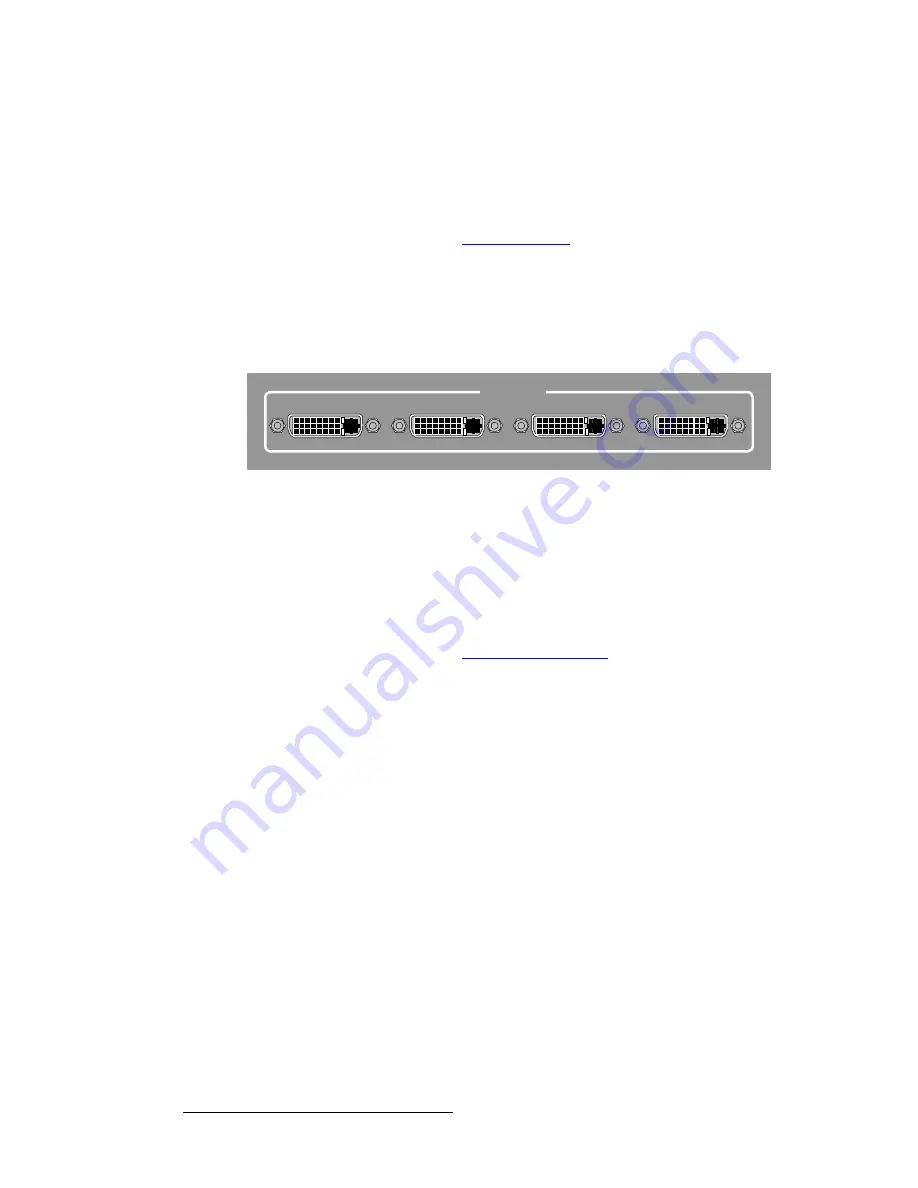

The figure below illustrates the

Inputs Section

:

Figure 2-2.

BlendPRO-II Inputs Section

The

Inputs Section

includes four DVI digital inputs per DDWG 1.0 specifications.

All four are DVI-D (digital, single link, receptacle) using DVI-I connectors to allow

flexible cabling choices. Please note:

~

Each input accepts DVI progressive RGB signals with a pixel clock

speed from 25 - 162MHz (1600x1200x60Hz).

~

Each input must be of the same resolution and H/V locked together.

In Appendix A, refer to the “

DVI Connector Pinouts

” section on page 38 for

pinout details.

INPUTS

1

2

3

4