10

Adjusting Mandrel/Film Tension…..

Each type of laminating film has different characteristics and may require laminator adjustment. The tension should be

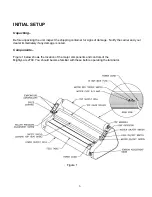

set so that the film moves over the heat shoes without wrinkles as the film enters the laminator. Best results are

obtained if tension adjustments are made while the unit is at operating temperature. If any adjustments are required use

the following procedure:

1. Switch the heaters on. Wait for the heat shoes to reach operating temperature.

2. Press the motor switch to on.

3. Locate the knob on the right side of the top supply mandrel. See Figure 1. Turn the knob to adjust the tension

(clockwise to increase, counter clockwise to decrease) until the film passes over the top heat shoe without wrinkles and

the web between the laminating and pull rollers is tight.

Note: This adjustment requires only a few degrees of turn. If

the knob is turned too far, you may stall the drive motor.

4. If necessary locate the knob on the right side of the bottom supply mandrel and adjust the tension as in step 3 above.

5. If you are not ready to laminate, turn the motor switch and heat switch off.

Setting Heat Shoe Temperature...

The laminator temperature should be adjusted according to the film thickness and the item being laminated. Contact

film manufacturer for recommended

temperature settings. Keep in mind that the temperatures listed are approximate

and different brands of laminating film and heavy paper stocks may require different temperatures. Also keep in mind

that when the machine is cold the warm-up time may be longer than the heat indicator light may suggest due to the

rollers not yet having sufficient heat distribution.

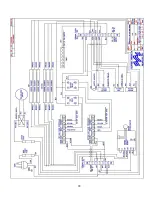

Use the heater controllers on the left side of the laminator to adjust the temperature of the heat shoes. Use the

temperatures in the table below as a guide.

Material

Temperature Range

1.5 mil (.0015”)

270°F - 325°F

3 mil (.003”)

260°F - 275°F

5 mil (.005”)

250°F - 270°F

10 mil (.010”)

250°F - 270°F

Adjusting Slitter Blades

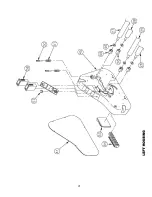

The slitter (figure 8) may be set to trim the web to the desired width as it exits the laminator. If an additional slitter

blade is installed (optional), two pages (side-by-side) may be laminated and trimmed in a single operation. (As the web

exits the unit, these pages may then be separated with the additional slitter blade).

Summary of Contents for MightLam 2700

Page 1: ...OPERATING INSTRUCTIONS MIGHTYLAM 2700 ROLL LAMINATOR ...

Page 19: ...19 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 22: ...22 ...