4. Mount the device (or the device and the bracket) to the machine or equipment at the desired location. Do not tighten the mounting

screws at this time.

5. Check the device alignment.

6. Tighten the mounting screws to secure the device (or the device and the bracket) in the aligned position.

Connect the Cables

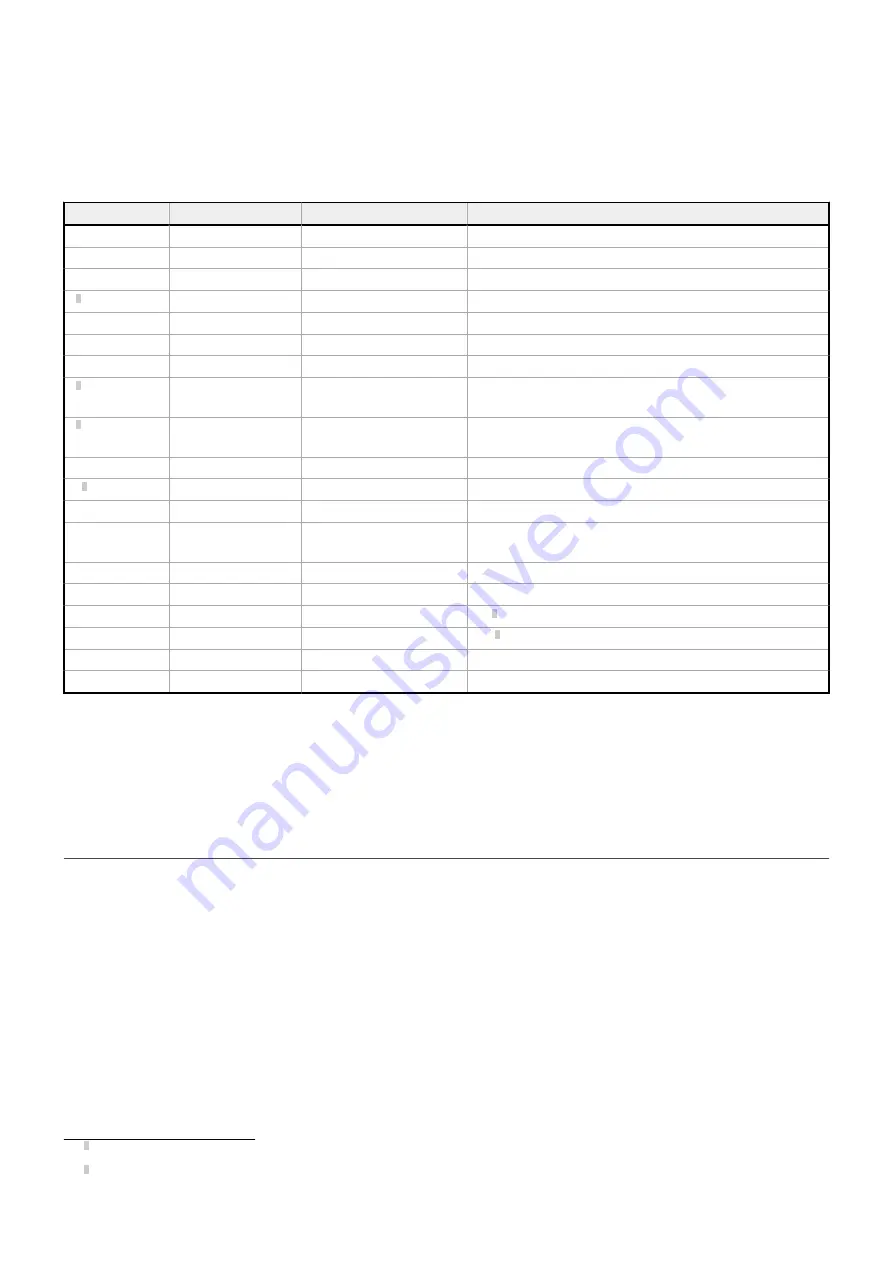

Table 2: Power and I/O Pinouts for MQDC2S-17xx

Pin

Wire Color

Name

Description

1

Brown

V dc

Power Supply Input V

2

Blue

GND

Power Supply Input Voltage -

3

White

I2B

Input Signal 2 (polarity insensitive)

4

3

Green

TX

Transmit Data of Auxiliary RS232

5

Pink

I1B

External Trigger B (polarity insensitive)

6

Yellow

I1A

External Trigger A (polarity insensitive)

7

Black

ID+

ID-NET n

8

3

Gray

O2

Configurable Digital Output 2 - positive pin

NPN or PNP short circuit protected and software programmable

9

3

Red

O1

Configurable Digital Output 1 - positive pin

NPN or PNP short circuit protected and software programmable

13

White/Green

I2A

Input Signal 2 (polarity insensitive)

14

3

Brown/Green

RX

Receive Data of Auxiliary RS232

15

White/Yellow

ID-

ID-NET network -

16

Yellow/Brown

O3

Output 3

NPN or PNP short circuit protected and software programmable

Connector Case

n/a

CHASSIS

Cable shield connected to chassis and 17-pin connector shell

RS232 Main Serial Interface

RS422 FD Main Serial Interface

10

Violet

-

RX-

4

11

Gray/Pink

RX

RX+

4

12

Red/Blue

-

TX-

17

White/Gray

TX

TX+

If using a TCNM-ACBB1 connection box, connect the reader using cable MQDEC-1703SS-DB25 and refer to the Instruction Manual for writing

details.

Use Cat 5e or superior M12 D-code cables, such as STP-M12D-4xx.

To meet EMC requirements:

•

Connect the reader chassis to the plant earth ground by means of a flat copper braid shorter than 100 mm

•

Conect pin "Earth" of the TCNM-ACBB1 connection box to a good earth ground

•

For direct connections, connect the cable shield to the locking ring nut of the connector

Simple Configuration

From the factory, all standard 1D and 2D ABR 7000 models are set up to read Data Matrix barcodes. To configure other codes, perform the

simple configuration using the Smart Teach Interface. A simple configuration does not require Barcode Manager software.

Smart Teach

Interface

Smart Teach is designed to improve ease of installation and maintenance

Status information is clearly presented by means of the five colored LEDs. The single push button provides access to the following modes.

•

Test includes bar graph visualization to check static reading performance

•

Aim/Autofocus turns on the laser pointers to aid positioning and focusing

•

Setup self-optimizes and auto-configures image brightness parameters

•

Learn automatically detects and recognizes a single code which is presented to it. Successive Learns will substitute the current code.

To configure multiple codes, use the Barcode Manager Auto-learn procedure

Quick access to the following modes is provided by using the push button:

1. Press the button. The Status LED gives visual feedback.

2. Hold the button until the specific mode LED is on (Test, Aim/Autofocus, Setup, or Learn).

3. Release the button to enter the specific mode.

After the button is pressed, the cycle of LED activation is as follows:

3 Referenced to GND; Outputs become opto-isolated and polarity sensitive when connected through the TCNM-ACBB1 connection box. See Instruction Manual for con-

nection details.

4 If using RS422, do not leave floating. See the Instruction Manual for connection details.

ABR 7000

P/N 207633 Rev. A

www.bannerengineering.com - Tel: +1-763-544-3164

3