20

english

4

Configuration (continued)

4.7.9 Scaling: Total measuring range

(Total measuring range in steps)

In this parameter, the number of steps into which the

nominal stroke is to be divided can be indicated. From this

the BTL7-T500… calculates the required step length. Step

lengths under 1 µm are smaller than the measurement

resolution and thus do not make sense.

Resolution (step width) =

Nominal length

Measuring range in measuring

units

This parameter indirectly determines the parameter

Scaling: Measuring steps per nominal stroke

, so that one

of the two parameters should always be set to zero. If both

Scaling: Measuring units per nominal stroke

and

Scaling:

Total measuring range

are set,

Scaling: Total measuring

range

has the higher priority.

4.7.10 Tolerated number of sign-of-life errors

(Max Master Sign-Of-Life failures)

If sign-of-life monitoring is activated in the controller, a

counter is incremented after each telegram. This allows the

BTL7-T500-... to recognize whether it has missed a

telegram. This parameter sets the number of errors from

which the device starts to a sign-of-life error in G1XIST2.

4.7.11 Speed unit (Speed measuring unit)

The speed can be selected from

Steps/1000 ms

,

Steps/100 ms

, and

Steps/10 ms

. The step length is

defined by the parameter

Scale: measurement steps per

nominal length

or

Scale: Entire measurement range

.

4.7.12 Diagnostic time for FMM

This parameter can only be set on modules with FMM.

If the number of magnets changes in flexible magnet mode

(FMM), a diagnostic is output. The time during which the

diagnostic is pending can be determined with this

parameter. The diagnostics time in milliseconds is 4x that

of the set value. This means a time between 4 ms and

1022 ms can be set. Entries below 35 ms have no effect,

since the magnetostrictive linear position sensor needs this

time in order to output a new, valid position value after the

number of magnets has changed (see

4.8

Services

The services distinguish between Master Class 1-/Slave

functions (MSAC_C1) and Master Class 2-/Slave functions

(MSAC_C2). The services differ in having different distance

access points (SAP = Service Access Point).

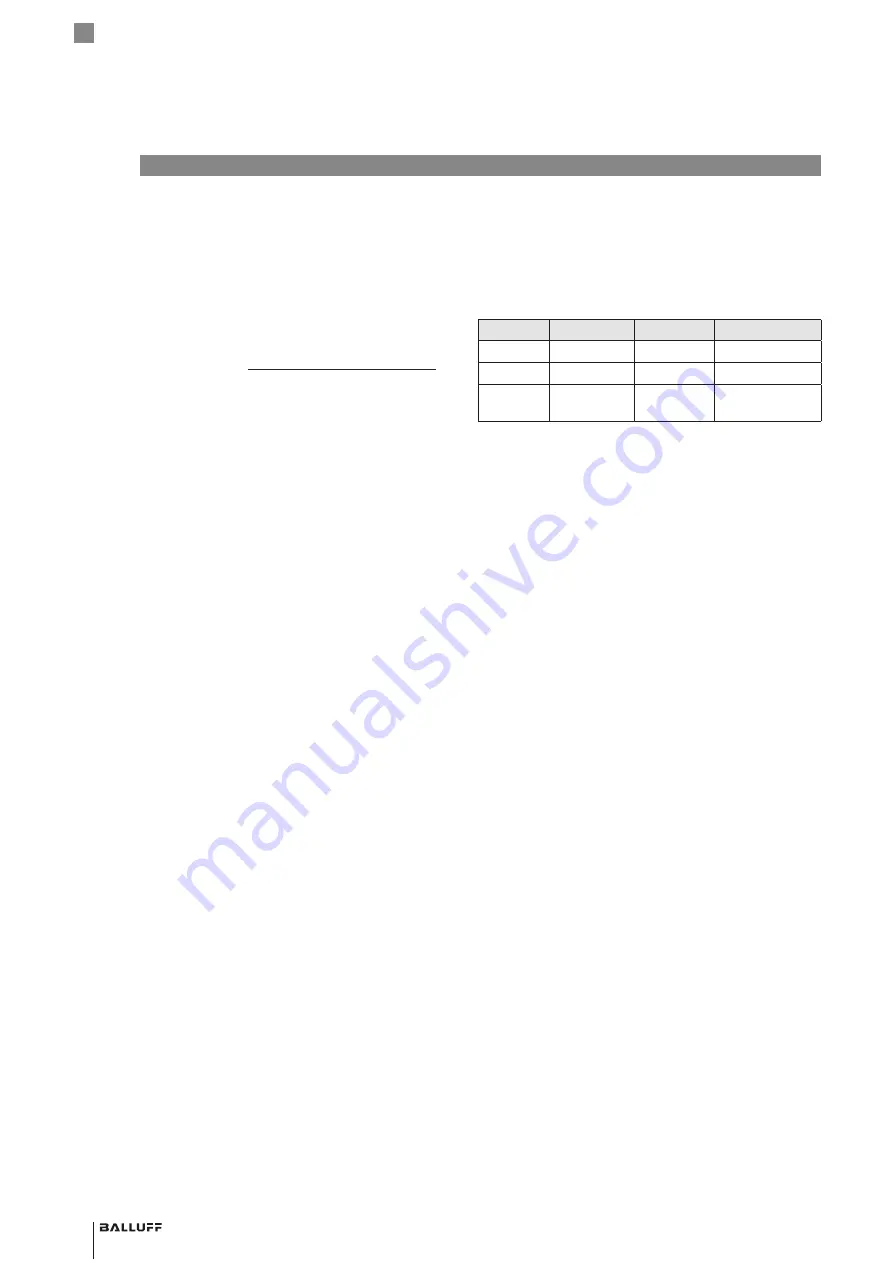

Function Master SAP Slave SAP Services

MSAC_C1

51

51

Read, Write

MSAC_C2

50

49

Initiate request

MSAC_C2

50

0…48

Abort, Read,

Write

Tab. 4-6: Assignment of SAPs for acyclic data communication

DP-V1

The following services are implemented in the

magnetostrictive linear position sensor:

–

MSAC_C1

(Master-Slave acyclic communication, Class 1)

– Read data record from a slave (Read)

– Write slave data record (Write)

–

MSAC_C2

(Master-Slave acyclic communication, Class 2)

– Initiate (open connection to slave)

– Read data record from a slave (Read)

– Write slave data record (Write)

– Abort (close connection to a slave)

The SAPs assigned for DP-V1 are different for Class-1-

Master and Class-2 masters. The assignments of the

individual SAPs to the services are shown ion Tab. 4-6.

Since data exchange with MSAC_C1 communication is

monitored in cyclical data exchange, no connection

opening or closing using Initiate/Abort is necessary as is

the case with MSAC_C2 connections. Errors in cyclical

data communication also affect acyclic data

communication and vice-versa.

After a Class-1-Master has turned on extended mode in

the

Set_Prm-Telegram

, it can communicate with a slave

using SAP 51 in

Data_Exchange

. After

Leave_Master

SAP

51 is again disabled. Note that SAP 50 and SAP 51 are

not turned on until data exchange.

BTL7-T500-…

Configuration Guide

Summary of Contents for BTL7-T500 Series

Page 1: ...BTL7 T500 Konfigurationsanleitung deutsch ...

Page 2: ...www balluff com ...

Page 42: ...BTL7 T500 Configuration Guide english ...

Page 43: ...www balluff com ...