www.balluff.com

21

english

Ignition protection

“nA” and “tb”

10.1 Accuracy

The specifications are typical values for the

BTL7-A/C/E/G… at 24 V DC and room temperature, with

a nominal length of 500 mm in conjunction with the

BTL-P-1013-4R, BTL-P-1013-4S, BTL-P-1012-4R or

BTL-P-1014-2R magnet.

The transducer is fully operational immediately, with full

accuracy after warm-up.

For special versions, other technical data may

apply.

Special versions are indicated by the suffix -SA

on the part label.

Repeat accuracy

Typical

±10 µm

Sampling rate

Dependent on the nominal length

At nominal length = 500 mm

1 ms…4 ms

1 ms

Non-linearity at

Nominal length ≤ 500 mm

Nominal length > 500 to ≤ 5500 mm

±50 µm

±0.01% FS

Temperature coefficient

1)

≤ 30 ppm/K

Max. detectable velocity

10 m/s

10.2 Ambient conditions

Operating temperature

−40°C…+60°C

Storage temperature

−40°C…+70°C

Relative humidity

< 90%, non-

condensing

Rod pressure rating

(when installed in hydraulic cylinders)

For Ø 8 mm

≤ 250 bar

For Ø 10.2 mm

≤ 600 bar

Shock rating

Continuous shock

per EN 60068-2-27

2), 3)

150 g/6 ms

150 g/2 ms

Vibration

per EN 60068-2-6

2), 3)

20 g,

10…2000 Hz

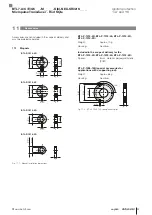

Degree of protection per IEC 60529

Connector SR32 (when attached)

IP67

Cable

IP68

2)

10.3 Supply voltage (external)

Voltage, stabilized:

BTL7-_5_ _-…

10…30 V DC

Ripple

≤ 0.5 V

ss

Current draw

(at 24 V DC)

< 120 mA

Inrush current

≤ 500 mA

Reverse polarity protection

4)

Up to 36 V

Overvoltage protection

Up to 36 V

Dielectric strength

(GND to housing)

500 V AC

10.4 Output

BTL7-A… Output voltage

Load current

0…10 V and 10…0 V

≤ 5 mA

BTL7-C… Output current

Load resistance

0…20 mA/20…0 mA

≤ 500 ohms

BTL7-E… Output current

Load resistance

4…20 mA/20…4 mA

≤ 500 ohms

BTL7-G… Output voltage

Load current

−10…10 V and 10…−10 V

≤ 5 mA

Short-circuit resistance

Signal cable to 36 V

Signal cable to GND

10.5 Input

Programming inputs La, Lb: High-active

BTL7-_5_ _-…

10…30 V DC

Overvoltage protection

Up to 36 V

1) Nominal length = 500 mm, magnet in the middle of the measuring range

2) Individual specifications as per Balluff factory standard

3) Resonant frequencies excluded

4) A prerequisite is that no current can flow between GND and 0 V in the

event of polarity reversal.

10

Technical data

BTL7-A/C/E/G5 _ _ -M _ _ _ _ -K(8)-NEX-SR32/K_ _ _

Micropulse Transducer - Rod Style

Summary of Contents for BTL7-A5 Series

Page 2: ...www balluff com ...