4-10 Input / Output

MN1957

www.baldormotion.com

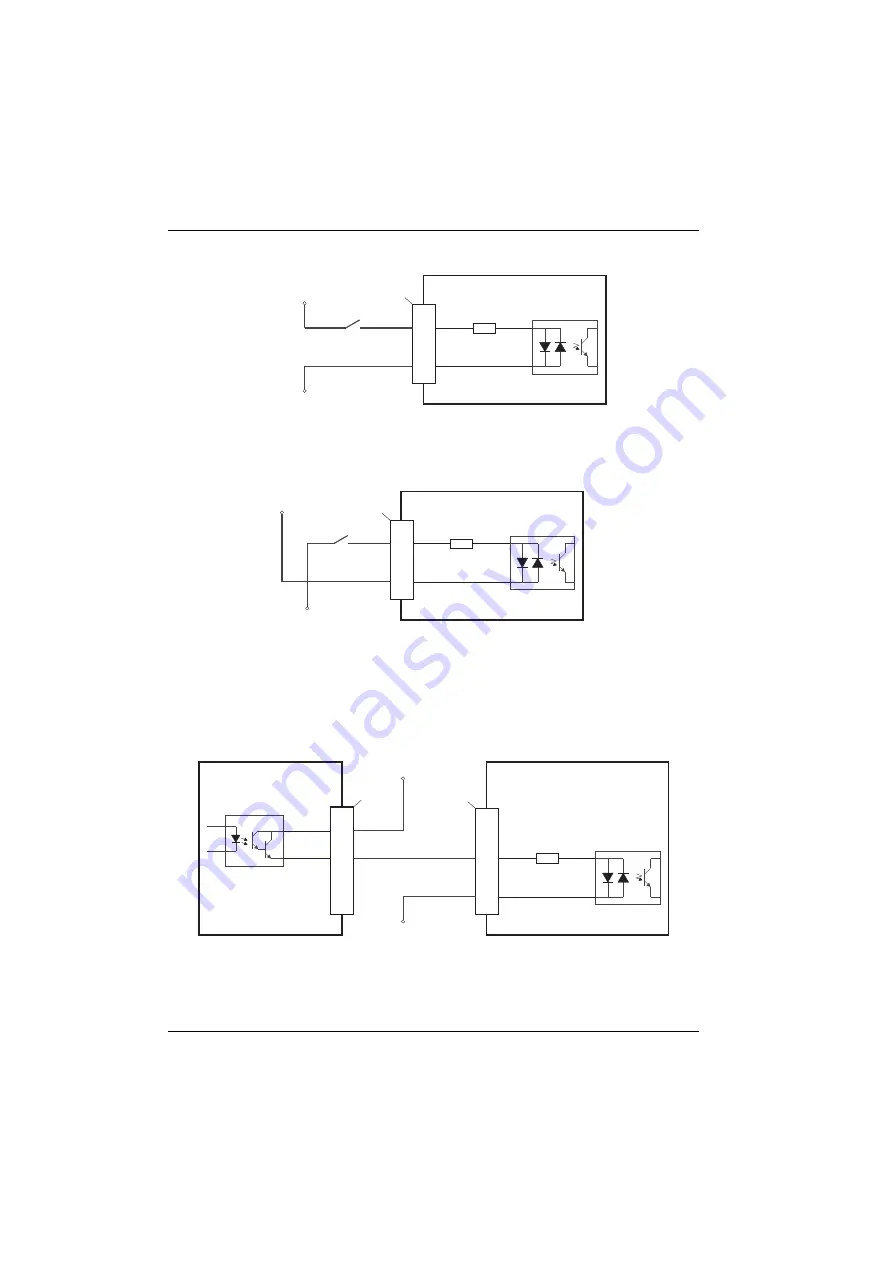

4.3.1.5 Typical digital input wiring

Figure 12: Digital input - typical ‘active high’ input connection using a switch

Figure 13: Digital input - typical ‘active low’ input connection using a switch

Note:

The circuits shown in Figures 12 and 13 are not suitable for use with fast inputs

DIN0 to DIN3. Using a mechanical switch, relay contacts or other source liable

to signal ‘bounce’ could cause unwanted multiple triggering.

Figure 14: Digital input - typical connections from a Baldor MicroFlex

NextMove E

S

B-2

D

IN

4

U

ser

supp

l

y

24V

U

ser

supp

l

y

GN

D

X9

8

9

CR

E

F

1

TLP

280

D

IN

4

U

ser

supp

l

y

GN

D

CR

E

F

1

NextMove E

S

B-2

X9

8

9

TLP

280

U

ser

supp

l

y

24V

NextMove E

S

B-2

MicroFlex

/

e

q

ui

p

ment out

p

ut

D

IN

4

Status

-

U

ser

supp

l

y

24V

U

ser

supp

l

y

GN

D

X9

X

3

8

2

3

9

CR

E

F

1

NEC

PS

2562

L

-1

TLP

280

Servo Systems Co. • 115 Main Road • P.O. Box 97 • Montville, NJ,

07045-0097 • (973) 335-1007 • Toll Free: (800) 922-1103

Fax: (973) 335-1661 • www.servosystems.com