16 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

Warning:

Do not install operational trim and spray

nozzles until the pipelines have been completely

blown down and thoroughly cleaned. All debris must

be removed to protect the trim from damage.

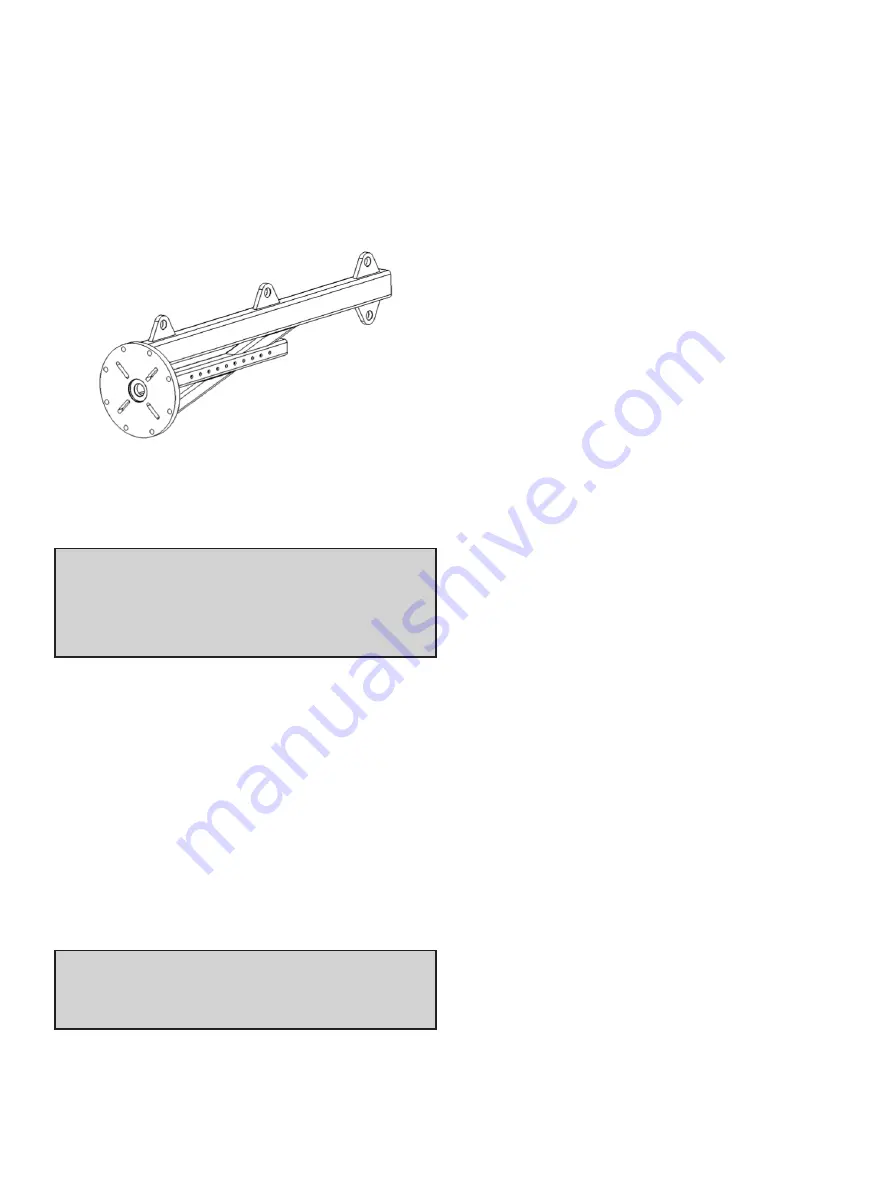

Trim Installation Device (TID)

A fixture to facilitate the safe and successful installation

or removal of trim from a valve body in the horizontal

orientation must be utilized. A local representative should

be contacted for information regarding the tool as trim-size

specific adaptors are required to mount the lifting tool.

For larger SteamForm valves installed in horizontal

orientation, special tool and care is required. Please

contact the Factory for recommendations.

Post Weld Heat Treatment and

Hydro-Testing

SteamForm valves are manufactured with either flanged

or butt weld end connections. For valves that require

welding into line, select welding rod that is compatible

with the valve connection material. Check the valve

specification sheet data for the body and end connection

material that is being supplied.

The applicable codes of the country or state of

installation specify welding and post weld heat treatment

requirements that must be followed. Verification of

localized welding temperatures by thermocouples is

advised.

Hydro-testing procedures can require a factory designed

test fixture, depending on whether or not the SteamForm

is used as a material or pressure class break point. In

this type of installation, isolation of the inlet section from

the outlet section is necessary to test each component

individually against its unique code required testing

conditions.

SteamForm Assembly

The SteamForm must be installed in line so the flow

through the valve follows the direction indicated on by the

flow arrow on the valve body.

After the steam lines are thoroughly cleaned and

hydrotested, it is safe to install the operating trim. For

start-up assistance from a certified technician, please

contact your local Baker Hughes Masoneilan sales office

or factory. For the complete installation procedure, please

refer to the SteamForm instruction manual.

Commissioning Spares

A full set of commissioning spares should be available on

site at all times to minimize the amount of downtime for

the SteamForm. Commissioning spares must include, at

a minimum, a full set of gaskets and packing to provide

the required soft-parts for reassembly.

Soft-parts such as gaskets and packing should never

be reused once they are removed from a valve. Do not

interchange components with parts supplied for other

valves.

Contact your regional Baker Hughes Sales office,

Aftermarket center or Channel Partner for spare parts

requests.

Turbine Bypass To Condenser

Applications

Several internal and external factors are introduced within

the turbine bypass applications, specifically in the bypass

to condenser application. The role of the SteamForm

becomes critical in ensuring equipment is protected

during the high pressure and temperature excursions.

Another major concern is for the limitation of noise as

high-energy steam is injected into a thin wall duct that

acts similar to a noise amplifier. These concerns are

addressed in more detail in the following sections.

Bypass System Requirements

The bypass to condenser design requires a significant

reduction in the heat level of the steam to reach an

enthalpy limit that is within the condenser design

limitations. Heat limits require the SteamForm to reduce

the steam temperature to the saturation range prior

to admission into the condenser. This application also

requires fast response to ensure safety valves remain

closed and prevent steam from venting outside of this

closed loop system.

Figure 13: Trim installation device

Warning:

Removing the operational trim during

these procedures is recommended to ensure the trim

is not damaged.