3 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

2. Maintenance

1. Reasonable precautions should be taken before beginning

work on the valve. Protective clothing, as required by the

specific line fluid, should be worn.

2. Before removing handle or the actuator from the valve, or

before removing seat retainer from a valve in dead end

service, close the valve and depressurize the line. The

eccentric design of the 39004 Series may allow line pressure

to open the valve if the handle / actuator is not in place while

the valve is under pressure.

DO NOT PRESSURIZE THE LINE WITHOUT A HANDLE

OR ACTUATOR ON THE VALVE.

3. The 39004 Series valve must be in the closed position to be

removed from the line.

4. Begin all work on a valve that has been removed from the

line by cleaning the valve, removing any grit or scale. When

handling the valve, care should be taken not to scratch the

disc edge or seats.

5. Replacement seats, seals and other parts are available from

authorized distributors. Contact your distributor or sales

representative for details of price and delivery.

3. Stem Seal Replacement

Refer to drawing on page 5 for parts identification.

1. If required, remove handle assembly. Remove socket head

cap screws (21) and lock washers (22). Remove mounting

bracket (20). For actuated valves, unbolt mounting bracket

from body and lift actuator assembly off stem. Note assembly

positions before removal.

2. Remove gland retainer nuts (14) and lock washers (13).

Remove gland retainer (11) anti-blowout retaining ring or

split ring (10) (depending on size), and gland ring (7).

3. Hook out stem seals (8), taking care not to scratch stem or

stuffing box bore. Do not remove thrust washer (9), unless

further valve disassembly is required.

4. Examine stuffing box bore and stem, clean as necessary

to remove any corrosion or foreign matter before installing

new seals.

5. Install new seals in stuffing box one at a time, TFE (white)

seals first, with the carbon fiber ring at the top. Stagger seal

ring joints 180° apart when installing. Tamp each ring to

bottom before installing next ring.

Note: On the larger valves it will be necessary to

compress each seal before adding the next.

6. Slide gland ring (7) over stem on top of seals (8). Install anti-

blowout retaining ring or split ring (10) (depending on valve

size). Slide gland retainer (11) over stem and onto gland

studs (12). Place lockwashers (13) and hex nuts (14) on

studs (12) and tighten finger tight. Tighten gland nuts (14)

evenly and alternately to the proper torque value given in

Table 2.

7. Remount actuator, or mounting bracket (20) with lock

washers (22) and cap screws (21) and handle (27). Tighten

handle set screw (28) to secure the handle to the valve

stem.

8. Operate valve open and closed several times, to check for

binding and to set the stem seals. Loosen gland nuts (14)

and retighten to torque value given in Table 2.

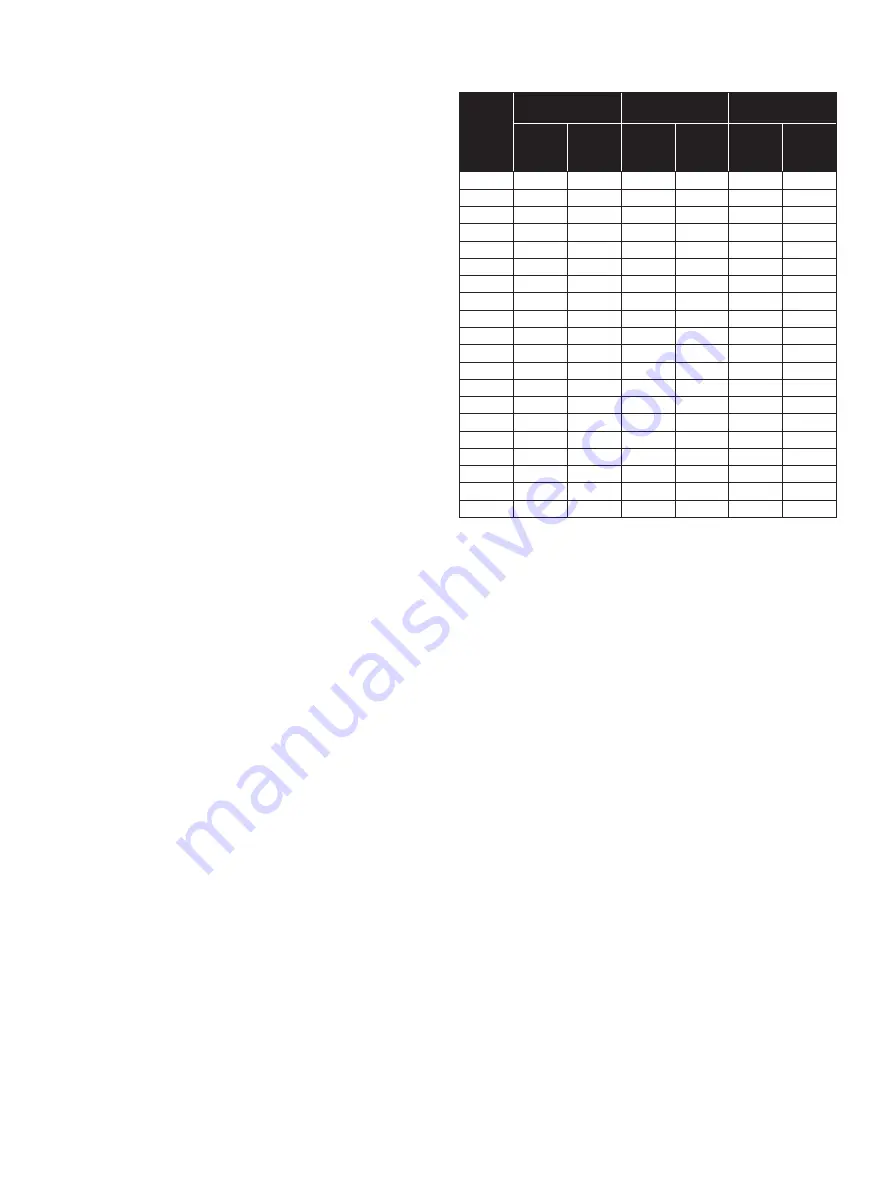

Table 1 - Total Number of Stem Seals

CF = Carbon Fiber

Valve

Size

Class 150

Class 300

Class 600

Number

of Stem

Seals

Material

CF / TFE

Number

of Stem

Seals

Material

CF / TFE

Number

of Stem

Seals

Material

CF / TFE

3

4

1 / 3

4

1 / 3

12

2 / 10

4

4

1 / 3

4

1 / 3

12

2 / 10

6

4

1 / 3

4

1 / 3

16

2 / 14

8

5

1 / 4

5

1 / 4

16

2 / 14

10

5

1 / 4

5

1 / 4

18

0 / 18

12

5

1 / 4

5

1 / 4

18

0 / 18

14

6

0 / 6

6

0 / 6

18

0 / 18

16

6

0 / 6

9

0 / 9

16

0 / 16

18

16

0 / 16

20

16

0 / 16

24

10

0 / 10

8

0 / 8

30

8

0 / 8

9

0 / 9

32

8

0 / 8

36

8

0 / 8

9

0 / 9

40

9

0 / 9

9

0 / 9

42

9

0 / 9

9

0 / 9

44

9

0 / 9

48

9

0 / 9

9

0 / 9

54

9

0 / 9

60

9

0 / 9

4. Seat Replacement

1. With the disc in the closed position, remove the valve from

the line.

2. Lay the valve down with the disc in the closed position and

the seat retainer side facing up.

3. Remove the socket head cap screws (17), the seat retainer

(16), and seat (15).

4. Carefully clean the seat area in the body and seat retainer.

Remove foreign matter, dirt, etc. Check disc seating area for

nicks or scratches.

5. Place the new seat (15) on disc (2), carefully centering it in

the recess in the body.

6. Align the holes in the seat retainer (16) with matching holes

in body and carefully place in position on top of seat (15).

Be careful not to shift retainer to align holes so that seat is

not shifted from correct position. Lightly grease cap screw

(17) threads and tighten down evenly, alternating from top

to bottom and side-to-side. Tighten to the torque value in

Table 2.

7. Operate valve several times and examine seat for any

damage before reinstalling the valve in the line.