3 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

4. Unpacking

Unpack valves and accessories carefully to avoid damage. The

control valves are packed in a clean state and the valve openings

are sealed with protective caps. The caps provide protection

against dirt and damage and should not be removed until the

valve is being fitted into service.

5. Installation

Before installing the valve, clean all piping carefully, removing

all dirt, grease, oil and other residues. The sealing surfaces

between control valve and piping must be cleaned carefully and

checked to ensure they are tightened properly. Flange gaskets

should not be used.

The valve must be fitted in the line so that the flow is

through the valve body in the direction of the arrow

marked on the housing. The arrow corresponds to

flow to close direction. All 31000 Series control valves

must be fitted in this manner since flow assists in

closing the plug.

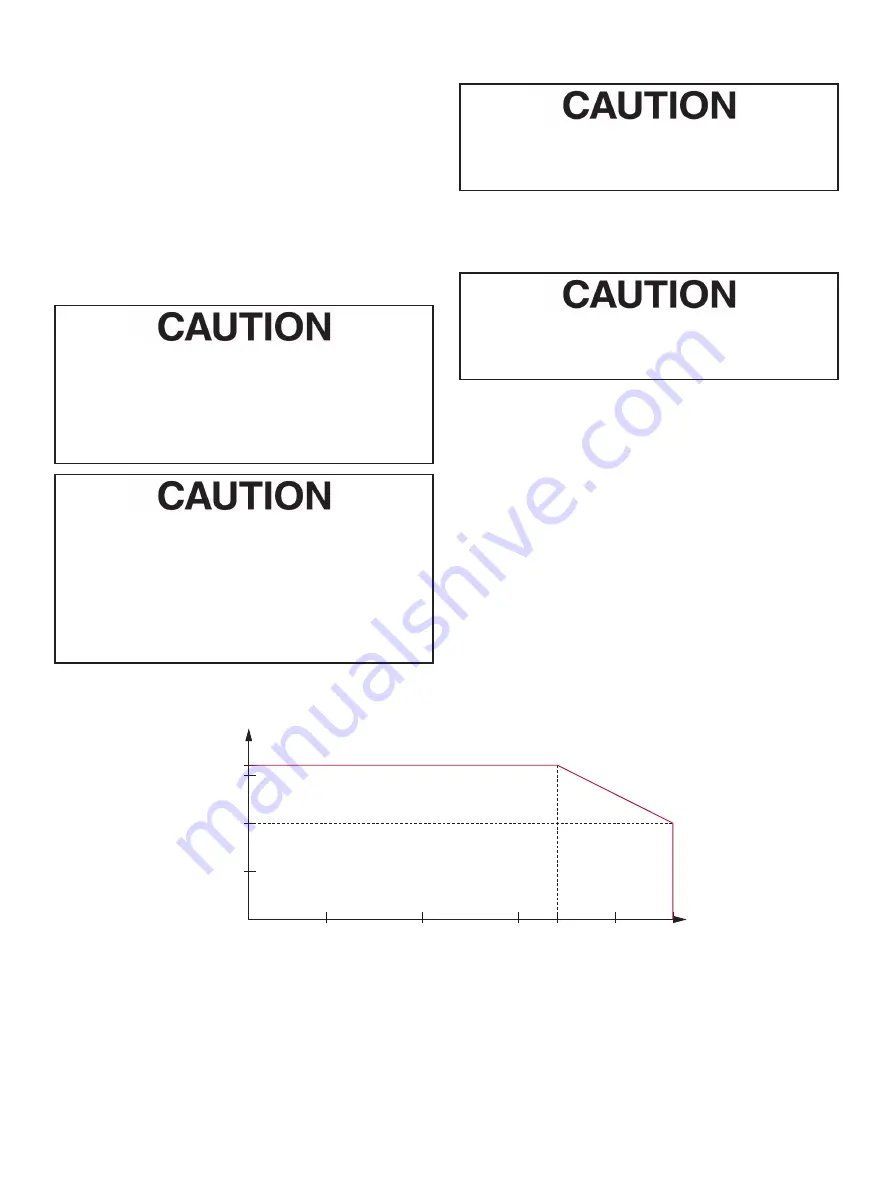

31000 Series valves are designed with a maximum

operating pressure of 232 psi (16 bar), this limit is set

by the lining. The bodies are available in different sizes

in accordance with DIN and ANSI standards. Before

fitting the control valve, the plant operator should

ensure that the maximum pressure the valve body

will be subjected to will not exceed the allowed value.

Refer to the diagram below.

6. Disassembly

Control valves, which have been in service should

be thoroughly cleaned before disassembly. Residues

present inside the valve can be harmful to health.

Note: All parts which come in contact with flow are

constructed of PTFE or PFA in standard versions of the

31000 Series. Particular care must be taken when handling

these parts since they can be easily damaged.

Prior to disassembly of the control valve, ensure that

the valve body has been depressurized. Accessories

(positioner, airset etc.) must be removed.

6.1 Actuator Disassembly

(Figure 5a and 5b)

1. Remove the rear and front covers (118 & 121) of the actuator

by releasing the screws (119). If necessary screw out the

handwheel (141) after removing the Truarc ring (138) and

washer (139).

2. Move the actuator to its intermediate position with

compressed air.

3. Remove the indicator (154), clevis pin clip (122) and clevis

pin (124), release the lever cap screw (137).

4. Depressurize the spring barrel. If the valve is not supplied

with a positioner, remove screw (127) and shaft cover (126).

5. Remove the yoke screws (19) (Figure 1) and lift off the

complete actuator unit and lever (135).

(bar)

°C

(15)

(10)

(5)

(0)

0

-20

50

100 120

150

180

°F

32

-4

122

212 248

302

356

(16)

psi

218

145

73

0

232

Pressure/Temperature Diagram