16

16

Material Insertion

1. Once the die set is properly installed, the material that matches the die can be inserted (I.E.

1-1/4”tube would go into a die mark DS-**-1250T-R***).

2. With the ratchet wheel in the home (0°) position insert the material through the counter die

and forming die and into the hook sleeve so that the material extends at least 1/4" past the

sleeve or until the until the material is at the position of the desired bend. The start of bend

mark is engraved with an “O” on the top of the die. Once the material is placed properly, the

counter die slide block assembly can be tightened.

Important

: Liberally apply lubricant along the counterdie and the 1/2 of the

material that contacts the counter die with a WD-40 style lubricant or equivalent. Do not

lubricate the bending die or the hook sleeve. Lubricating the bending die and hook sleeve will

encourage slipping of material during the bend.

Follow the bending steps to bend the material to the desired degrees.

Material Insertion Limitations

•

Using the Material Layout formula, calculate the amount of material that will be pulled

through the die.

•

Verify that the material is long enough to provide at least 80% coverage in the counter die at

the end of the bend. This will provide enough material remaining in the counter die to be fully

supported in plastic slide.

•

Extreme care must be taken when bending material with an existing bend. There must be

enough straight material to complete the bend. If there is not enough material the bent part

of the material will crash into the counter die and damage the machine and tooling.

IMPORTANT:

Orienting your material in this fashion will cause damage to your tooling

and machine!! DO NOT pull bent material into the counter die! Make sure you have enough

straight material on the draw side of the material to create your bend.

Summary of Contents for RDB-050

Page 1: ...OPERATOR S MANUAL ROTARY DRAW BENDER MODEL RDB 050 B8000 2015 Baileigh Industrial Inc ...

Page 13: ...11 11 GETTING TO KNOW YOUR MACHINE I B C E G D F H A ...

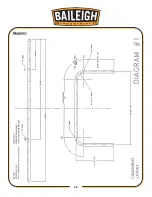

Page 27: ...25 25 Diagram 1 ...

Page 28: ...26 26 Diagram2 ...

Page 30: ...28 28 TOP FRAME ASSEMBLY PARTS DIAGRAM ...

Page 32: ...30 30 RATCHET WHEEL ASSEMBLY PARTS DIAGRAM ...