30

30

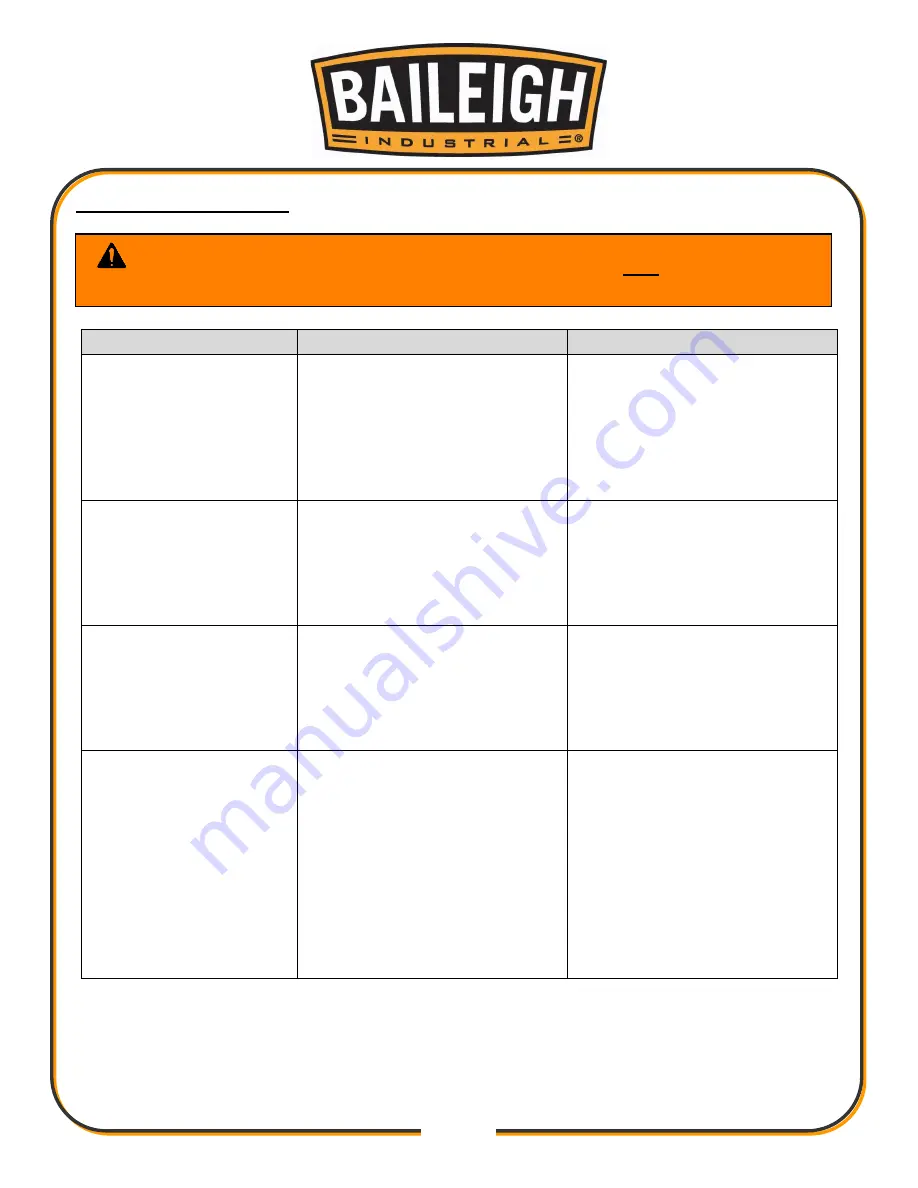

TROUBLESHOOTING

Symptom

Possible Cause(s)

Corrective Action

1. The motor cannot

start.

1. The power isn't on.

2. The fuse of electric circuit has

blown.

3. The electric cable is

damaged.

4. The switch isn’t “on”.

5. The motor is damaged.

1. Check all the electric circuit.

2. Change the fuse.

3. Repair or change the cable.

4. Check the switch.

5. Change the motor.

2. The saw blade cannot

cut or the cutting speed is

slow.

1.The saw blade is installed

backwards

2. The saw teeth contain

unwanted grit.

3. The saw has not been used

for long time.

1. Turn over the saw blade and

install it again.

2. Remove the grit, re-sharpen

the blade teeth.

3. Repair and re-grind the saw

teeth to make them sharp again.

3. Slipping saw blade.

1. The saw blade is not straight.

2. The upper wheel isn’t parallel

with the lower wheel,

3. The guides are not adjusted

correctly

1. Reinstall the saw blade.

2. Adjust the upper wheel to

make it parallel with the lower

one.

3. Re-adjust the guides so the

blade does not slip

4. Excessive Blade

Breakage.

1. Incorrect blade tension.

2. Incorrect speed or feed.

3. Blade rubs on wheel flange.

4. Teeth too coarse for material.

5. Teeth in contact with the

material before the saw is

started.

6. Misaligned guides.

7. Cracking of blade weld.

1. Adjust to where blade just

does not slip on wheel.

2. Consult machine chart or

handbook.

3. Adjust the wheel alignment.

4. Contact Baileigh Industrial for

recommended blade type.

5. Contact material after blade

has been started.

6. Adjust as necessary.

7. Replace blade

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Summary of Contents for WBS-12

Page 28: ...26 26 PARTS DIAGRAM...

Page 33: ...31 31 NOTES...

Page 34: ...32 32 NOTES...

Page 35: ...33 33 NOTES...