11

11

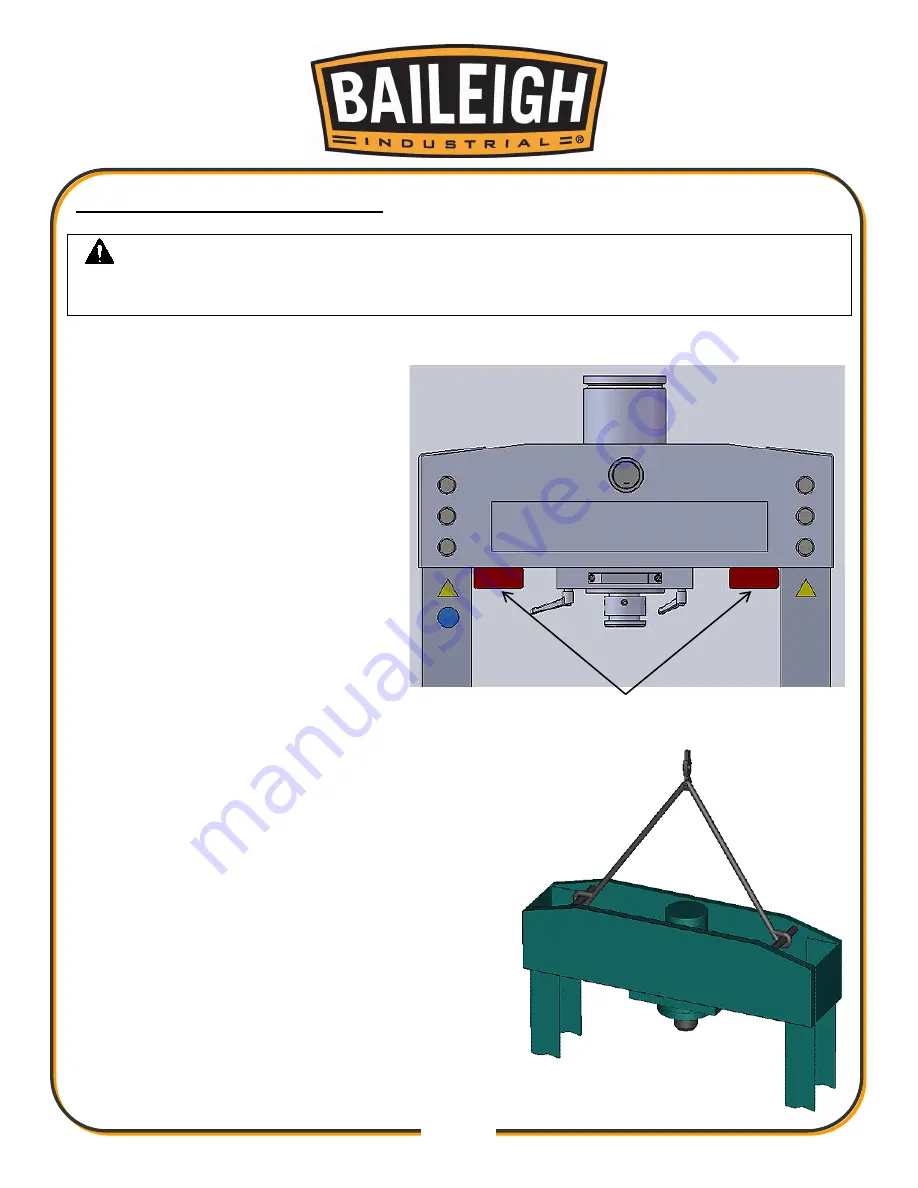

TRANSPORTING AND LIFTING

IMPORTANT:

Lifting and carrying operations should be carried out by skilled workers,

such as a truck operator, crane operator, etc. If a crane is used to lift the machine, attach the

lifting chain carefully, making sure the machine is well balanced.

Follow these guidelines when lifting with truck or trolley:

•

The lift truck must be able to lift at

least 1.5 – 2 times the machines

gross weight.

•

Make sure the machine is balanced.

While transporting, avoid rough or

jerky motion, and maintain a safe

clearance zone around the transport

area.

•

Use a fork lift with sufficient lifting

capacity and forks that are long

enough to reach the complete width

of the machine.

•

Remove the securing bolts that

attach the machine to the pallet.

•

Approaching the machine from the

side, lift the machine on the frame

taking care that there are no cables or pipes in the

area of the forks.

•

Move the machine to the required position and

lower gently to the floor.

•

Level the machine so that all the supporting feet

are taking the weight of the machine and no

rocking is taking place.

Follow these guidelines when lifting crane or

hoist:

•

Always lift and carry the machine with the lifting

holes provided at the top of the machine.

•

Use lift equipment such as straps, chains, capable

of lifting 1.5 to 2 times the weight of the machine.

•

Take proper precautions for handling and lifting.

Lift with Forks Here

Summary of Contents for HSP-176M-1500-HD

Page 3: ...ELECTRICAL SCHEMATIC 38 Electrical Parts List 38 TROUBLESHOOTING 39 ...

Page 19: ...16 16 GETTING TO KNOW YOUR MACHINE A I G H L J B F K C E D ...

Page 30: ...27 27 Using the Machine Incorrect Correct ...

Page 31: ...28 28 Incorrect Correct ...

Page 37: ...34 34 RAM PARTS DIAGRAM ...

Page 39: ...36 36 HYDRAULIC PUMP PARTS DIAGRAM ...

Page 43: ...40 40 NOTES ...