42

42

LUBRICATION AND MAINTENANCE

Daily Maintenance

•

Check daily for any unsafe conditions and fix immediately.

•

Check that all nuts and bolts are properly tightened.

•

Do a general cleaning by removing dust and metal chips from the machine.

•

Inspect the saw blade for wear.

•

Clean the lubricating coolant drain screen.

•

Top off the coolant tank.

•

Check that the blade guards and emergency stop buttons are in good working order.

•

At the end of the day, raise the bow to its up position and release some of the blade tension.

Weekly Maintenance

•

Clean the machine and the area around it.

•

Lubricate threaded components and sliding devices.

•

Apply rust inhibitive lubricant to all non-painted surfaces.

•

Wipe and grease the vise screw and sliding surfaces.

•

Inspect blade brush wheel and clean if needed.

•

Clean coolant pump strainer basket.

•

Remove chips from inside the guard housing for the saw blade.

•

Use compressed air to clean the blade guides and guide bearings.

Monthly Maintenance

•

Check the tightening of the motor flywheel screws.

•

Check the blade guide bearings for wear. (replace if necessary)

•

Tighten any loose bolts or screws on the gear motor, pump, and safety switches.

•

Clean coolant tank

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Page 36: ...33 33...

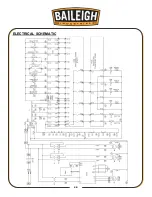

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...