7

5.0

Specifications

Stock# ........................... BA9-1232697 .... BA9-1232698 ....... BA9-1232699 ...... BA9-1232700 ....... BA9-1232701

Model# ........................................ AP-0 .................. AP-1 ..................... AP-2 .................... AP-3 ................ AP-5HD

Pressure (ton) ........................... ½ Ton ................. 1 Ton .................... 2 Ton ................... 3 Ton ..................... 5Ton

Max Work Height (in.) ................. 4-3/4 ........................ 5 ..................... 7-1/2 .................. 11-1/2 ......................... 17

Diameter of Work (in.) ................. 6-5/8 ........................ 8 ................... 10-3/4 .................. 11-3/8 ......................... 17

Anvil Diameter (in.) ..................... 3-1/2 .................. 3-1/2 ................. 6-11/16 ................ 6-11/16 ..................... 9-3/4

Size of Ram (in.) ................ 3/4 x 7-7/8 ............ 1 x 9-1/8 ............. 1-1/4 x 13 ............ 1-1/2 x 18 ............. 2 x 27-1/2

Ram Bore (in.) ................................ 3/8 ..................... 1/2 ........................ 1/2 ....................... 1/2 ........................ 1/2

Ram Travel (in.) ........................... 4.72 ..................... 5.9 ...................... 9.05 ..................... 12.6 ...................... 18.1

Base Size (in.) ....................... 4 x 9-1/2 ............ 5 x 9-1/2 ....... 6-3/8 x 15-3/4 ............ 8-1/2 x 18 ............. 9-7/8 x 26

Overall Dimensions:

Length (in.) ............................ 9-5/16 .................. 9-1/2 ................... 15-3/4 .................. 18-1/8 ......................... 27

Width (in.) ................................ 6-5/8 .................. 7-1/2 ......................... 10 .................. 10-1/4 ......................... 13

Height (in.) .......................... 10-3/8 ...................... 12 ................... 17-1/2 .................. 22-1/2 ................... 31-1/2

Net Weight (lb.) ......................... 17-1/2 ................ 25-1/2 ................... 67-1/2 ...................... 108 ....................... 262

Shipping Weight (lb.) ....................... 19 ................ 26-1/2 ................... 69-1/2 ...................... 116 ................. 296-1/2

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, Baileigh Industrial reserves the right to change specifications at any time and without

prior notice, without incurring obligations.

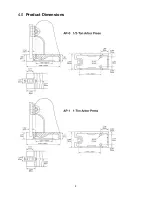

6.0

Setup and Operation

Arbor Press Features

The arbor press consists of a cast iron base, an

anvil, a pressing handle with lock knob, and a rack-

type ram.

The removable anvil has four cutouts used for

pressing on or off bearings or various sized

bushings.

Set-up and Operation

Note:

Numbers in parentheses below correspond to

item numbers in the exploded view on page 8.

Do not use the arbor press

without first mounting the arbor press to the

workbench and anchoring the workbench to the

floor. Mount the arbor press to the workbench

using bolts and using the holes in the base (1).

Changing Ram Position

The ram has a flat surface on one end and a hole

on the other end. The hole is used to accept the

punch inserts. Change-out the ram as follows:

A. Remove the handle by loosening the knob

(17). Remove one cap (5) from the handle

assembly. Remove handle (6) from the pinion

(16).

B. Remove the pinion retainer (14) by backing

off the Set Screw (13). Slide the pinion

retainer (14) off of the pinion (16).

C. Pull up on the ram (4) to provide slack and

remove the pinion (16) from the arbor press.

D. Pull the ram (4) out the top of the arbor press

body. Turn the ram (4) end-for-end.

Tip: If ram does not freely come out of arbor

press body, loosen the two hex nuts (11) on

side of arbor press body and the two hex nuts

(11) on the front plate (12).

E. Repeat steps A – D in reverse.

Maintenance

A. Periodically lubricate the arbor press with a

light machine oil.

B. Wipe off or vacuum the accumulated debris

and dust after using the arbor press.

C. Periodically check the ram for side-to-side and

front-to-back play. If the play is excessive,

loosen the hex nuts (11) and adjust (tighten) the

screws (10 on side, 9 in front) just enough to

eliminate the excess play. Tighten them equally

to assure even contact with the ram (4).

D. Once the play is eliminated, hold the screw

(10 or 9) in position and tighten the hex nut

(11). Check to make sure the amount of play

is acceptable.