88

9

The preferred method of installation is by means of a saddle with 1” NPT out

-

let. On steel pipelines a weld-on type fitting may be substituted.

1. Attach the saddle to a section of pipe that has at least 10 diameters of

straight pipe ahead and five diameters of straight pipe behind the saddle.

2. Remove the sensor assembly from the mounting/isolation valve by

loosening the hex cap over the stem collar and the cover to the mounting/

isolation valve and detaching the assembly. Set aside taking care not to

damage impeller/shaft assembly.

3. Attach the pipe thread end of the valve to the saddle using a pipe joint

compound and tighten the joint.

Do not apply sealing compound to the top

thread of the valve. It is sealed with an o-ring.

4. Attach the tapping adapter, Data Industrial part number A-1027 to the top

of the valve.

5. Any pipe tapping machine with a 1” pipe thread connection may be used.

Use a cutter appropriate for the pipe material being tapped.

6. Attach the tapping machine to

the tapping adapter. Ensure

that all connections and seals

are tight.

7. Slowly open the valve by

rotating the handle 90° and lower the cutter past the valve ball to

the pipe. Drill the 1” nominal hole according to the manufacturer’s

instructions. Withdraw the cutter past the valve ball, close the valve

and remove the tapping tool.

8. Remove the Data Industrial tapping adapter from the top of the

valve.

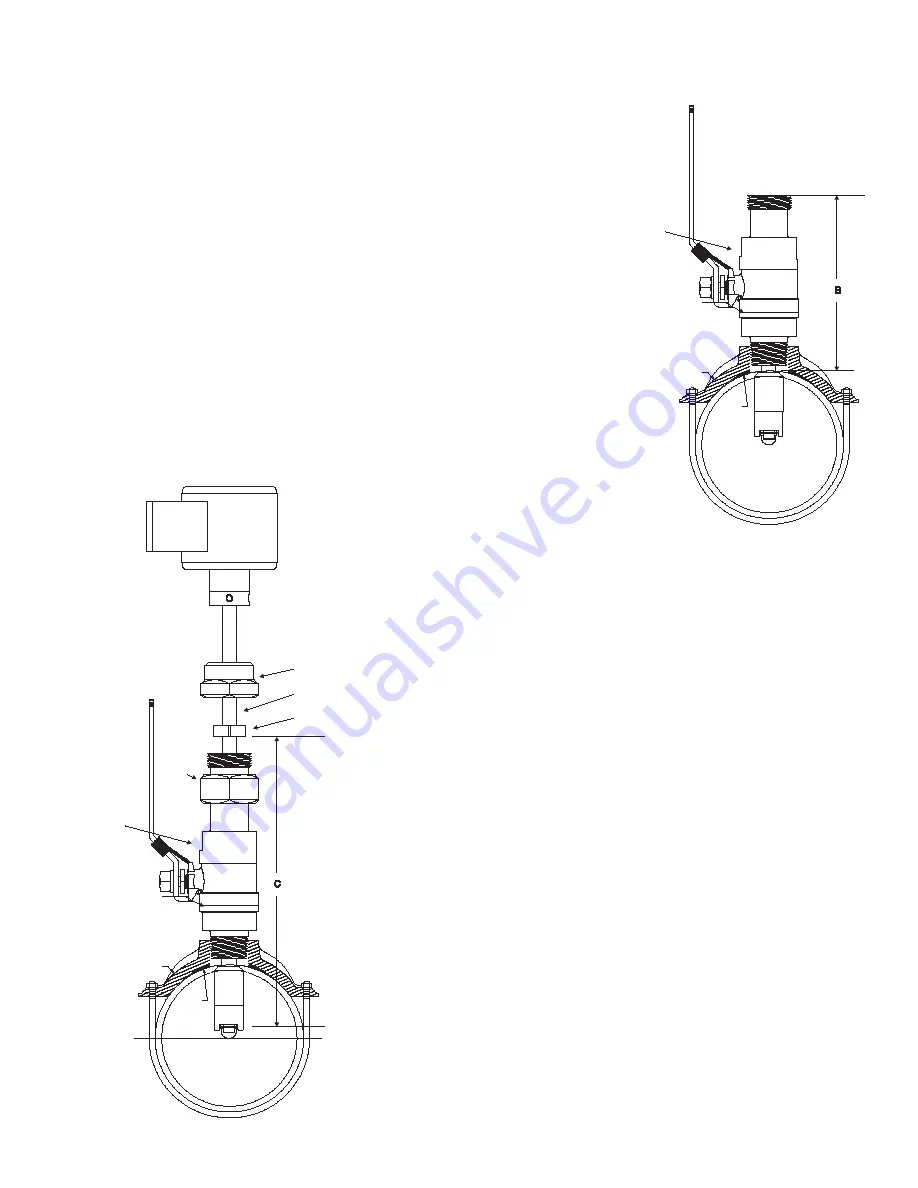

9. The sensor rotor assembly is to be located a fixed distance from the

center of the pipe. To position the impeller at this depth, a reference

measurement for the pipe size and schedule is used. Look up the

pipe size and schedule number in

Table A

and note the reference

number. Next, measure from the outside wall of the pipe to the top

of the ball valve “B” in Figure 8. Add this number to the reference

measurement.

The resulting number is the distance from the recess of the sensor

tip to the bottom of the stem collar “C” in Figure 9. Insert the metal

tab of a tape measure into the recess of the flow sensor tip. Extend

the tape up the stem and mark the shaft with a pencil. Slide the

collar along the shaft until its bottom surface is at the mark on the

stem. Tighten the cap screw on the collar. When the sensor is

reassembled, this will set the insertion depth of the sensor.

Pipe Saddle

(ref.)

Gasket

(ref)

Ball Valve

Stem Collar

Stem

Hex Cap

Cover

Pipe Saddle

(ref.)

Gasket

(ref)

Ball Valve