Reinstalling the Cover Assembly

Badger

Meter recommends that a new O-ring be used after each teardown and reassembly of the cover assembly To assure a

tight seal, make sure the O-ring is positioned correctly on the housing and that the O-ring and cover assembly are clean and

free of dirt or residual traces of old O-ring material If necessary, use silicone grease to help retain the O-ring and to serve as a

lubricant in reassembling it to the housing

Cover bolts should be tightened in a crisscross pattern similar to Turbo head bolts Torque 2" and 3" cover assembly bolts to

16…18 ft-lb Torque the bolts for the 4" and 6" cover assemblies to 35…40 ft-lb

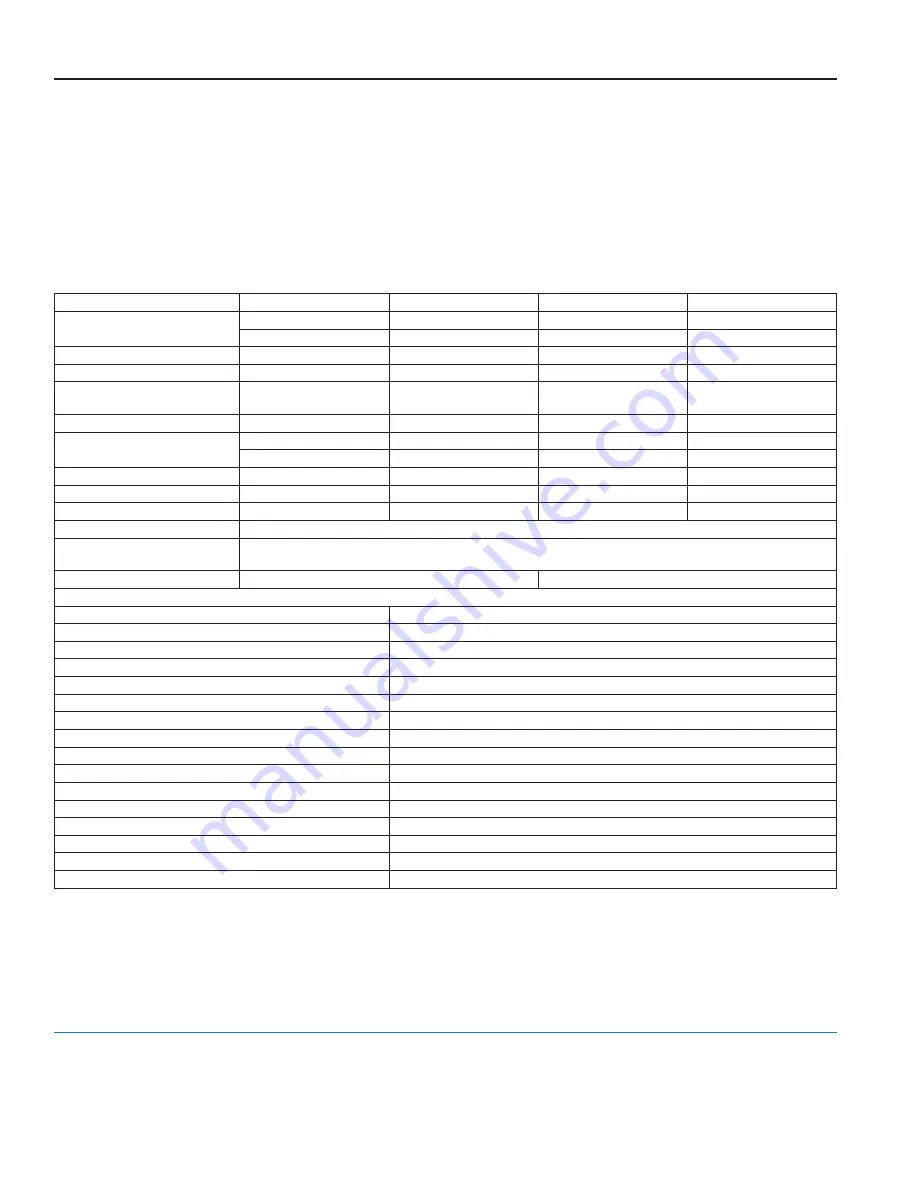

SPECIFICATIONS

Compound Series Model

2" (50 mm)

3" (80 mm)

4" (100 mm)

6" (150 mm)

Meter Flanges, Class 150

2" elliptical or round

3" round

4" round

6" round

(50 mm)

(80 mm)

(100 mm)

(150 mm)

Typical Operating Range

0 5…200 gpm

0 5…450 gpm

0 75…1000 gpm

0 75…2000 gpm

(100% ± 1.5%)

(0 1…45 m

3

/h)

(0 1…102 m

3

/h)

(0 17…227 m

3

/h)

(0 17…454 4 m

3

/h)

Low Flow Registration

(95% minimum)

0 25 gpm (0 06 m

3

/h)

0 25 gpm (0 06 m

3

/h)

0 375 gpm (0 09 m

3

/h)

0 375 gpm (0 09 m

3

/h)

Maximum Continuous Flow

170 gpm (38 3 m

3

/h)

400 gpm (90 3 m

3

/h)

800 gpm (181 6 m

3

/h)

1500 gpm (340 5 m

3

/h)

Pressure Loss at Maximum

Continuous Flow

5 4 psi at 170 gpm

6 0 psi at 400 gpm

11 0 psi at 800 gpm

9 3 psi at 1500 gpm

(0 38 bar at 38 3 m

3

/h)

(0 41 bar at 90 3 m

3

/h)

(0 75 bar at 181 6 m

3

/h)

(0 64 bar at 340 5 m

3

/h)

Crossover Flow Rate, Typical

12 gpm

12 gpm

20 gpm

30 gpm

Pressure Loss at Crossover

3 5 psi (0 24 bar)

4 0 psi (0 28 bar)

4 0 psi (0 28 bar)

5 0 psi (0 35 bar)

Minimum Crossover Accuracy

97%

97%

97%

95%

Maximum Operating Pressure

150 psi (10 bar)

Maximum Operating

Temperature

105° F (41° C)

Test Plug

1-1/2"

2"

Materials

Meter Housing & Cover

Lead-free bronze alloy

Turbo Cast Head

Lead-free bronze alloy

Nose Cone & Straightening Vanes

Thermoplastic

Rotor

Thermoplastic

Rotor Radial Bearings

Lubricated thermoplastic

Rotor Thrust Bearing

Sapphire jewels

Rotor Bearing Pivots

Passivated 316 stainless steel

Calibration Mechanism

Stainless steel & thermoplastic

Measuring Chamber & Disc

Thermoplastic

High Flow Valve

Stainless steel & thermoplastic

Magnets

Ceramic

Register Lens

Glass

Register Housing & Cover

Thermoplastic or bronze

Trim

Stainless steel

Drain Plug (3/4")

Stainless steel or lead-free bronze alloy

Test Plug

Stainless steel or lead-free bronze alloy

Recordall® Compound Series Meter, Lead-Free Bronze Alloy, Sizes 2", 3", 4" & 6"

www.badgermeter.com

Making Water Visible, GALAXY, ORION and Recordall are registered trademarks of Badger Meter, Inc Other trademarks appearing in this document are the property of their respec-

tive entities Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists © 2016 Badger Meter, Inc All rights reserved

Making Water Visible®

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S A de C V | Pedro Luis Ogazón N°32 | Esq Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Europe, Middle East Branch Office | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Office #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s r o | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s r o | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland I Badger Meter Swiss AG I Mittelholzerstrasse 8 I 3006 Bern I Switzerland I +41-31-932 01 11

Legacy Document Number: RCS-IOM-1