2

©2021 Babcock-Davis, Inc.

Rev 9/2021

Installation, Operation & Maintenance

Single-Part Stair Nosings

–

Ribbed Bar

Model: BSTSB

Tool List

•

Tamping tool

•

Screwdriver, Phillips

•

Drill (for recessed nosing)

•

Rabbit drill bit, 3/8” (for recessed nosing)

•

Screws, #10 (for mechanically fastened nosings)

•

Construction adhesive (for mechanically fastened nosings)

•

Clean-up tools

–

see Maintenance section on Cleaning

INSTALLATION

Slip-resistant metal stair nosings are designed to be fully embedded in the

substrate (most often concrete) which provides total support for the nosing.

Any voids left between the underside of the metal stair nosing and the substrate

will allow flexing of the stair nosing itself. It is vital that the installer tamp down

the stair nosings to totally seat into the substrate and fully rest upon any riser

return, such as in pan-filled steps. This action will prevent the occurrence of

hollows and voids, which can lead to flexing and cantilevering of the nosing.

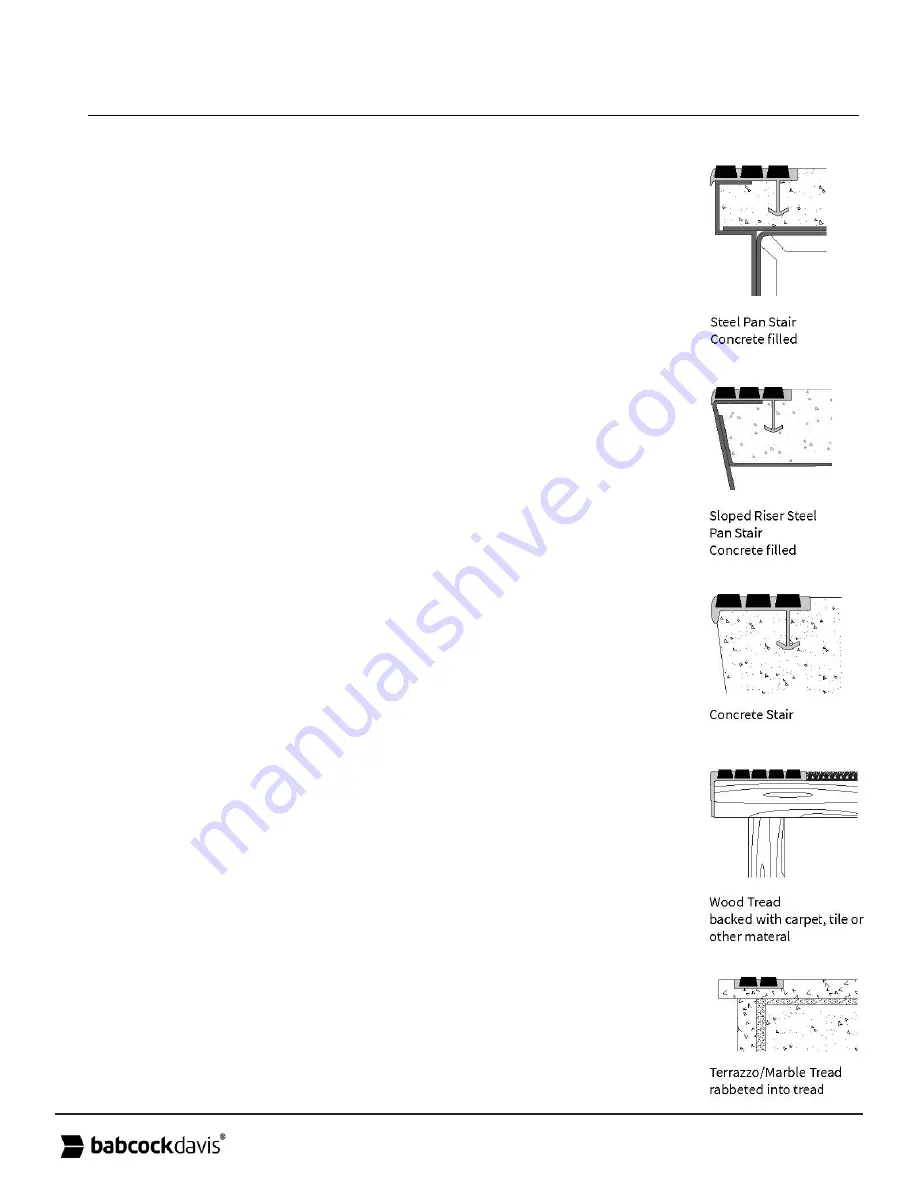

Cast-In

(Steel Pan Stairs, Poured Concrete or Terrazzo):

1. Pour the concrete

2. Place the stair nosing into position in the concrete

3. Tamp the stair nosing to ensure proper concrete formation around the

anchors on the undersides

Mechanically Fastened

(Poured Concrete)

1. Block out the concrete on the front edge of the stair to the exact height

and width of the nosing.

2. Pour the concrete.

3. After concrete is set remove block-out and place the stair nosing into

position.

4. Secure nosing with expansion screws.

Mechanically Fastened Surface Mount

(Wood, Marble or Terrazzo Stairs)

1. Align nosing flush to end of wood tread.

2. Fasten with #10 wood screws in pre-drilled, countersunk holes.