IR-B03 / IR-B03-T Page 12

7.

Troubleshooting

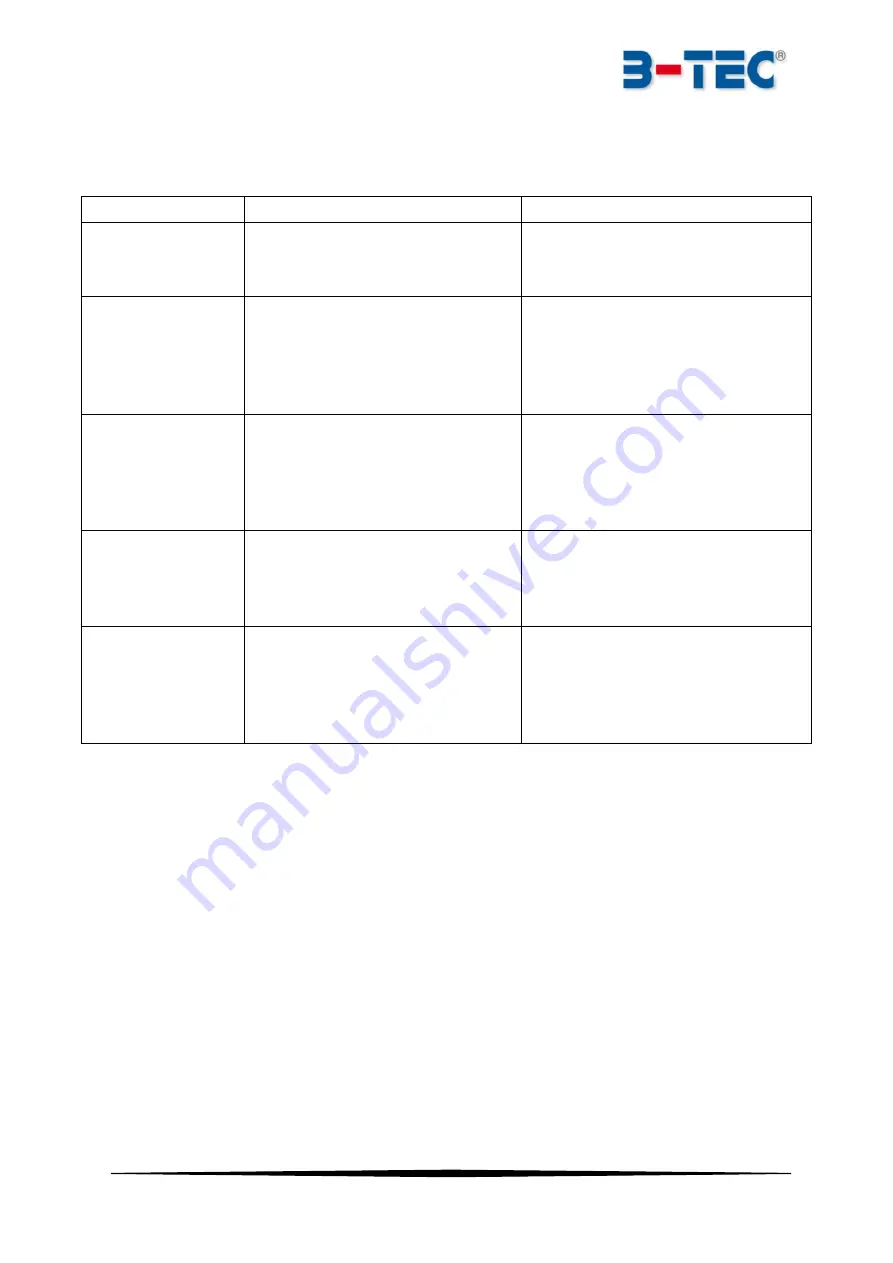

Issue

Possible cause

Possible solution

Uneven curing

Emitter not properly pointed/ad-

justed to the curing surface

Adjust emitter properly to the cur-

ing surface

Small pores (bubbles)

on the cured surface

Emitter too close to curing sur-

face

Curing too fast

Paint with fast thinning agent

Increase distance

Increase pre-curing time

Use standard or slow thinning agent

Poor curing or trans-

parent coating

Emitter too far away from curing

surface

Curing time too short

Paint layer too thick

Decrease distance

Increase full-curing time

Apply thinner paint layer

Stains

Full-curing time too long

Emitter too close to curing sur-

face

Decrease full-curing time

Increase distance

Fuzzy edges

The painted surface area is too

large for the infrared emitter

Curing in two steps

Move device for second curing step

Pre-curing only for first step. Do not

use pre-curing for second step.

For optimal curing performance, we recommend to work out the optimal operating procedures, cur-

ing times and distances according to the local natural conditions, working environment and the types

of paints used.

Above specifications, drawings or diagrams are descriptive and subject to revision. If there are any

discrepancies or changes, actual products shall prevail without otherwise notification.