OUTPUT

BOX

(USE CONNECTOR OPTIONS “E” & “F”

FOR M737A REPLACEMENTS)

+5 TO +24 VOLTS

*

ØB

*

(SEE LINE DRIVER OPTIONS)

ØA

COMMON

GROUND

CABLE BELDEN 8723

OR EQUIVALENT

RED

BLUE

GREEN

BLACK

B

C

E

A

E

D

A

F

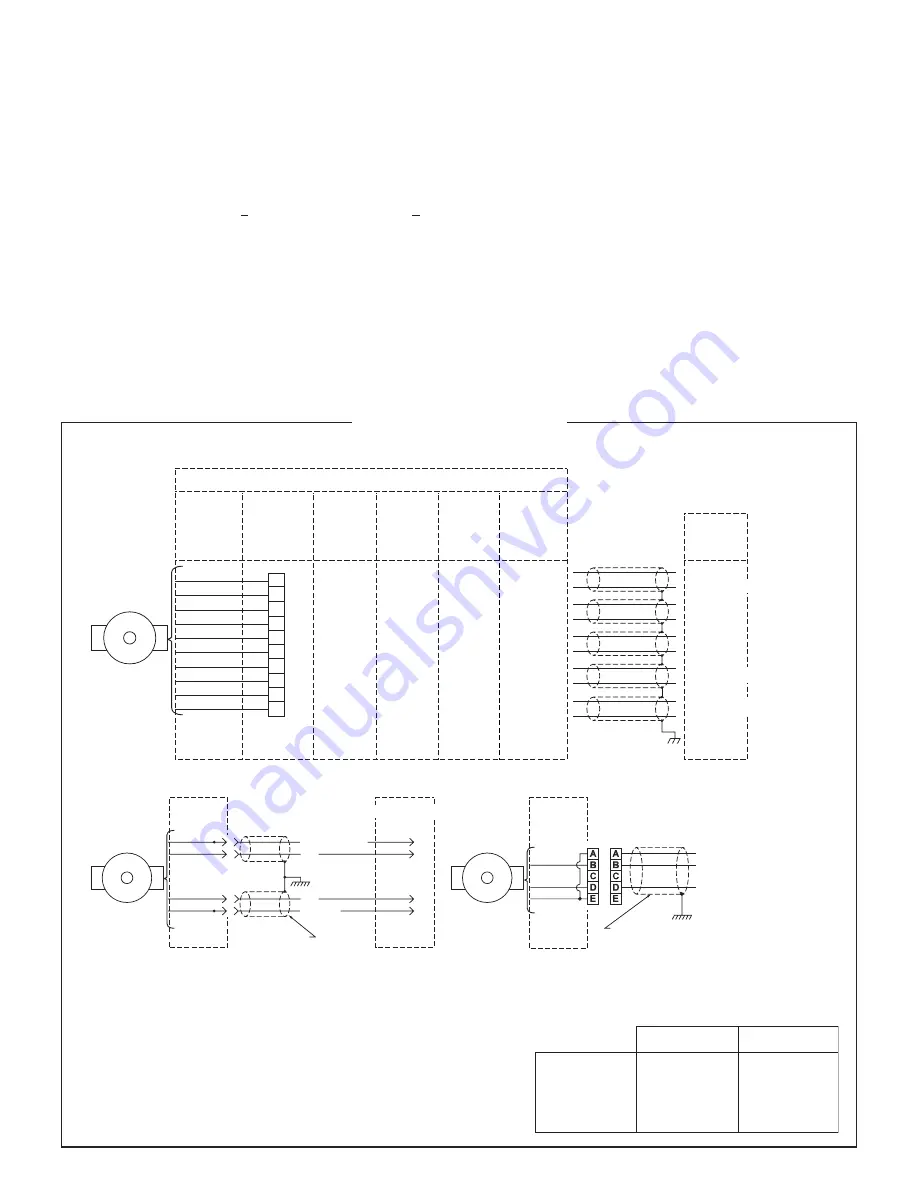

SINGLE ENDED TWO PHASE WIRING APPLICATIONS

CABLE BELDEN 8771

OR EQUIVALENT

COMMON

+5 TO +24 VOLTS

*

SIGNAL

GROUND

OUTPUT

BOX

(USE CONNECTOR OPTIONS “H” & “J”

FOR M727A REPLACEMENTS)

RED

GREEN

BLACK

SINGLE ENDED SINGLE PHASE WIRING APPLICATIONS

*

(SEE LINE DRIVER OPTIONS)

OPTION D

M940 REPLACEMENT

OPTION

“W” & “N”

REF

SIGNAL

OPTION

“A” “B” “C”

“K” “L” “M”

OPTION

“A” “B” “C”

“K” “L” “M”

With Mod.

030

OPTION

“P” “V”

“X” & “Z”

OPTION

“T”

OPTION

“R” & “S”

SIGNAL CODING TABLE

BLACK

RED

GREEN

YELLOW

BLUE

GRAY

ORANGE

WHITE

BROWN

VIOLET

F

D

A

H

B

J

C

K

not used

not used

F

D

A

H

B

I

C

J

1

2

3

4

5

6

7

8

9

10

1

6

2

7

3

8

4

9

5

10

not used

not used

COM

+V

ØA

ØA

ØB

ØB

Z

Z

C

C

DIFFERENTIAL TWO PHASE WIRING APPLICATIONS

A

B

D

G

E

H

C

I

F

J

+5 TO +24 VOLTS

*

= MARKER

= ØA

∏

4

*

(SEE LINE DRIVER OPTIONS)

–

–

–

–

WIRING DIAGRAMS

NOTES:

Marker output for connector options “E” & “F” - Pin “D”

Marker output for connector options “H” & “J ” - Pin “C”

Avtron standard warranty applies. Copies available upon request.

Specifications subject to change without notice.

BELDEN

2 PAIR

3 PAIR

4 PAIR

6 PAIR

TYPICAL WIRE SELECTION CHART

for 18 AWG, multiple pair, individually shielded

9368

9369

9388

9389

6062C

6063C

6064C

6066C

ALPHA

For bidirectional operation of the encoder, proper phasing of the two

output channels is important. Phase A channel leads phase B channel

for clockwise shaft rotation as viewed from the anti-drive or accessory

end of the motor (M3 mounting end).

CORRECTIVE ACTION FOR PHASE REVERSAL

1) Remove Power.

2) Exchange wires on cable, either at encoder cable end, or at

speed controller end (but not both).

a) Single Ended 2 Phase Wiring (see wiring diagram)

Exchange A and B at the use end of the wires.

b) Differential 2 Phase Wiring (see wiring diagram)

Exchange either A with A in the phase A pair OR B with B

in the phase B pair but NOT both.

3) Apply Power.

4) Verify encoder feedback is correct, using hand rotation of

shaft, or jog mode of the speed controller.

Interconnecting cables specified in the wire selection chart are based

on typical applications. Refer to the system drawing for specific cable

requirements where applicable.

Physical properties of cable such as abrasion, temperature, tensile

strength, solvents, etc., are dictated by the specific application.

General electrical requirements are: stranded copper, 22 thru 16

gauge (Industrial EPIC Connector options can use 14 AWG), each wire

pair individually shielded with braid or foil with drain wire, 0.05 uF

maximum total mutual or direct capacitance, outer sheath insulator,

1,000 ft. max. See Wire Selection Chart for some suggested cables.

NOTE

When using the industrial connector (“G”, “P”, “V”, “X”,

or “Z” options), the minimum wire size is 20 gage, and

20 gage (only) wire ends must be tinned with solder

before connection at the

screw terminals.