HS6A

1

8 9 0 1 E . P L E A S A N T VA L L E Y R O A D • I N D E P E N D E N C E , O H I O 4 4 1 3 1 - 5 5 0 8

T E L E P H O N E : ( 1 ) 2 1 6 - 6 4 2 - 1 2 3 0 • FA X : ( 1 ) 2 1 6 - 6 4 2 - 6 0 3 7

E - M A I L : t a c h s @ n i d e c - a v t r o n . c o m • W E B : w w w. a v t r o n e n c o d e r s . c o m

Nidec-Avtron Makes the Most Reliable Encoders in the World

Encoder Instructions

MODEL

HS6A

HOLLOW SHAFT 6mm-15mm BORE

DESCRIPTION

The Avtron Model HS6A is a light mill duty absolute encoder. It

expresses the position of rotation as an output message or value.

HS6A can measure a single turn of rotation or multiple rotations. The

HS6A measures the shaft rotation and position without the need for

external power or internal batteries or capacitors through its internal

gearbox system. The HS6A operates down to zero speed and can be

used for both control and instrumentation applications.

CAUTION

Do not utilize HS6A in hazardous locations which

require ATEX, UL, CUL, CSA, or other explosion protection

certification. HS6A is not certified for hazardous

locations.

The HS6A is designed for direct mounting on shafts and utilizes a

tether mount to secure the housing.

The HS6A features an interchangable set of sizing inserts to allow

the same unit to fit shafts over the full size range, 6-15mm. Note

that the optional thru-shaft 12mm unit can also be resized 6-12mm

using a different set of sizing inserts.

The HS6A uses optical sensors; to protect the optical sensors and

bearing systems HS6A features extensive seal systems. (Option “X”

unsealed is only available/standard on 12mm thru-shaft).

SAFETY

The HS6A is not considered as a safety device and is not suitable for

connection into a safety system.

CAUTION

Be careful not to damage clamping fingers of hollow

shaft during handling. Do not tighten clamping collar

before installation onto motor shaft.

WARNING

Installation should be performed only by qualified

personnel. Safety precautions must be taken to ensure

machinery cannot rotate and all sources of power are

removed during installation.

INSTALLATION

Refer to the back page of these instructions for outline and mounting

dimensions.

Equipment needed for installation

Supplied:

HS6A Encoder

Standard flat metal tether (2.48” [63mm] BC)

Optional:

Mating plugs

Mating cable assemblies

Not Supplied:

Hex Wrenches

Dial Indicator Gauge

Caliper Gauge

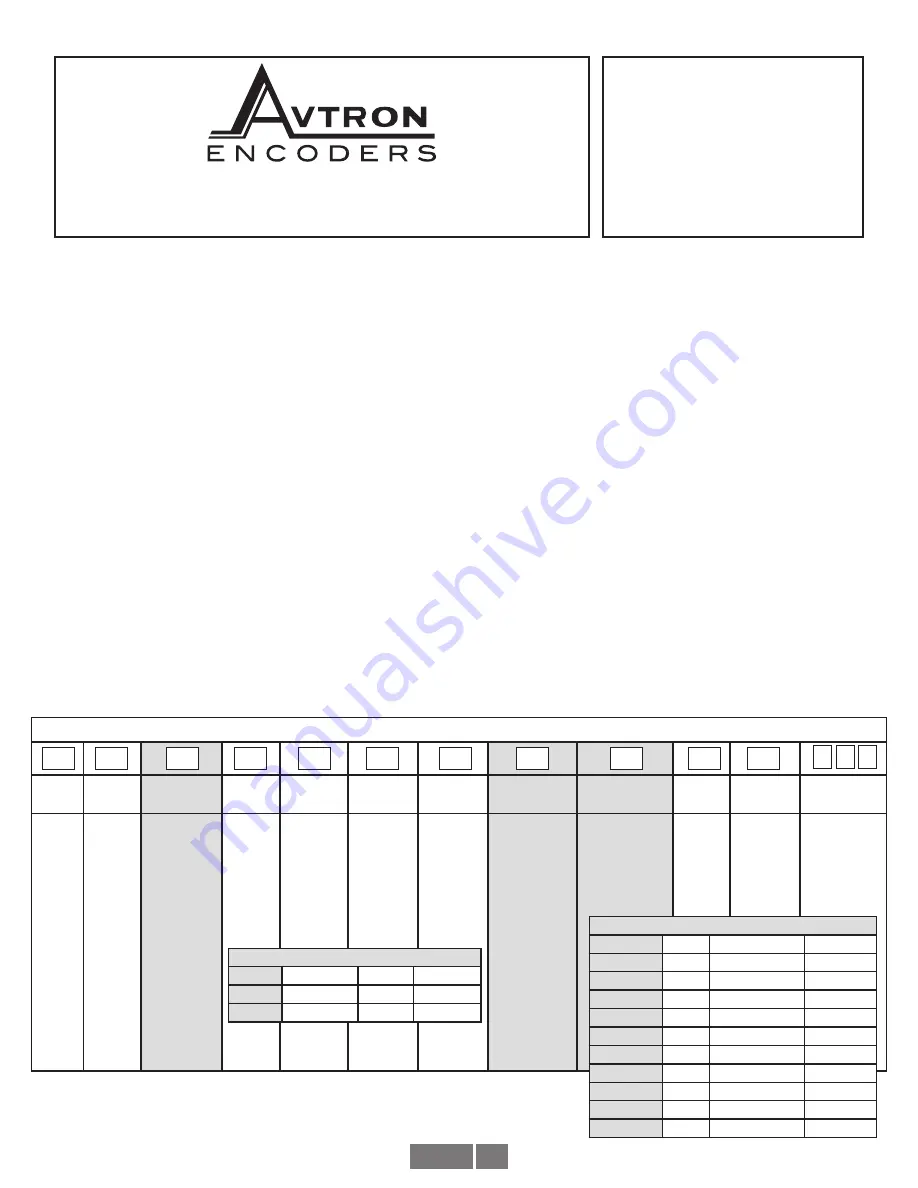

HS6A PART NUMBERS AND AVAILABLE OPTIONS

Model Sensor

Bus

Style

Shaft

Size

Turns/

bits

PPR/bits

per turn

Connector

Mounting

Output

IP

Rating

Special

Option

HS6A

A-

Optical

C-

CANOpen

D-

DeviceNet

F-

CANSafe

K-

POWERLINK

L-

Parallel

M-

ModbusTCP

Ethernet

N-

Profinet IO

P-

Profibus DP

R-

Ethernet/IP

S-

SSI

1-

58mm

housing

L-

6mm

M-

8mm

N-

10mm

P-

12mm

R-

15mm

(EOS only)

Z-

All metric

sizes

X-

0/0- single

turn

2-

4096/12

4-

16384/14

2-

4096/12

3-

8192/13

4-

16384/14

6-

65536/16

A-

1xM12/5 pin

B-

2xM12/5 pin

C-

3xM12 4/4/5

or 4/4/4 pins

D-

2xM12/4/5 pin

E-

M12/8 pin

F-

M23/12 pin

G-

M27/26pin

J-

2x cable entry

K-

3x cable entry

M-

M23/8pin

Hengstler

N-

M23/8pin

Stegmann

Q-

M23/8pin

Kubler

W-

Cable, 1m

E-

EOS only

U-

EOS or Thru

(12mm SSI only)

1-

Binary

2-

Gray

X-

None, IP54

A-

IP66 shaft

seals

S-

IP66 seals,

stainless

housing

000-

none

9xx-

special

cable

length

xx=length

0.3m/ft

MOUNTING COMPATIBILITY

Housing

Bore Size

Mounting IP/Sealing

1

M, N, P, R, Z E

A, S

1

P

U

X

STANDARD CONNECTORS & OUTPUT FORMATS

Bus

Code

Connectors

Output

CANOpen

C

A, B, C, J, K, W

1

DeviceNet

D

A, W

1

CANSafe

F

K

1

POWERLINK

K

C

1

Parallel

L

G, W

1, 2

ModbusTCP

M

D

1

Profinet

N

C

1

Profibus DP

P

C, J, K

1

EtherNet/IP

R

C

1

SSI

S

E, F, W

1, 2