TESTING AND TEST SET

-

UP

Page 14

The H

-

1, H

-

1 (light pedal) and H

-

1

-

A Controlair

Valve can be tested after repair using the test

arrangement shown below.

Pressure control valves of this nature should be

tested for the following:

1.

Function

2.

Pressure Range

3.

Leakage

4.

Flow Capacity

5.

Response

The adjustment affecting these points has been

described in the previous section. General

instructions for accomplishing the five tests above

are as follows.

1. Function:

The H

-

1 and H

-

1

-

A type Controlair

Valves are spring returned pedal actuated 3

-

way pressure graduating valves. A pedal

actuates the valve to increase, decrease or

maintain graduated air pressure to a separate

delivery line. This function should be checked

using test arrangement shown.

2. Pressure Range:

Supply pressure at

“

IN

”

port

will be delivered as graduated pressure to

“

Out

”

port delivery line depending on value of

control spring being used and pedal position. In

pedal release position the out delivery line is

connected to exhaust. Depressing the pedal

actuates the graduating control portion to

deliver graduated pressure to the out delivery

line. See

“

Adjustments

”

to adjust valve. After

valve is adjusted, check that the zero and

maximum pressure ranges are generated in

delivery line as per

“

Identity Schedule

”.

3. Leakage:

Set supply pressure to 20 psi above maxi-

mum delivery pressure of valve being tested. Using

soap solution, coat the valve at pipe bracket and

spring housing parting lines. No leakage is permitted

in any pedal position.

A. On all valves with spring ranges less than 100 psi,

set supply lines pressure to 100 psi. Depress pedal

to full travel position and hold. Close valve in sup-

ply line to

“

IN

”

port and valve in delivery line from

“

OUT

”

delivery line pressure gage. A pressure drop

of no more than 2 psi in 30 seconds is permitted.

B. On all valves with spring ranges 100 psi and above,

set supply line pressure to 100 psi. Depress pedal

to deliver 95 psi to delivery line from

“

OUT

”

port.

Close valve in supply line to

“

IN

”

port and valve in

delivery line from

“

OUT

”

port to trap the supply

pressure at the valve. Observe the

“

OUT

”

delivery

line pressure gage. A pressure drop of no more

than 2 psi in 30 seconds is permitted.

4. Flow Capacity:

Set supply line pressure to 100 psi

regardless of control spring rating of valve. Depress

pedal to full travel position. The delivery volume or

volumes from

“

OUT

”

port should be inflated with time

limits shown on Table 1. Release pedal quickly from

full travel position to release position. The delivery vol-

ume or volumes connected to

“

OUT

”

port should be

“

exhausted

”

within time limits shown in Table 1.

5. Response:

Depress pedal to full travel position. Fully

open the test valve at delivery volume from

“

OUT

”

port. Observe the delivery pressure gage. A pressure

drop of no more than 3 psi is permitted. Release pe-

dal.

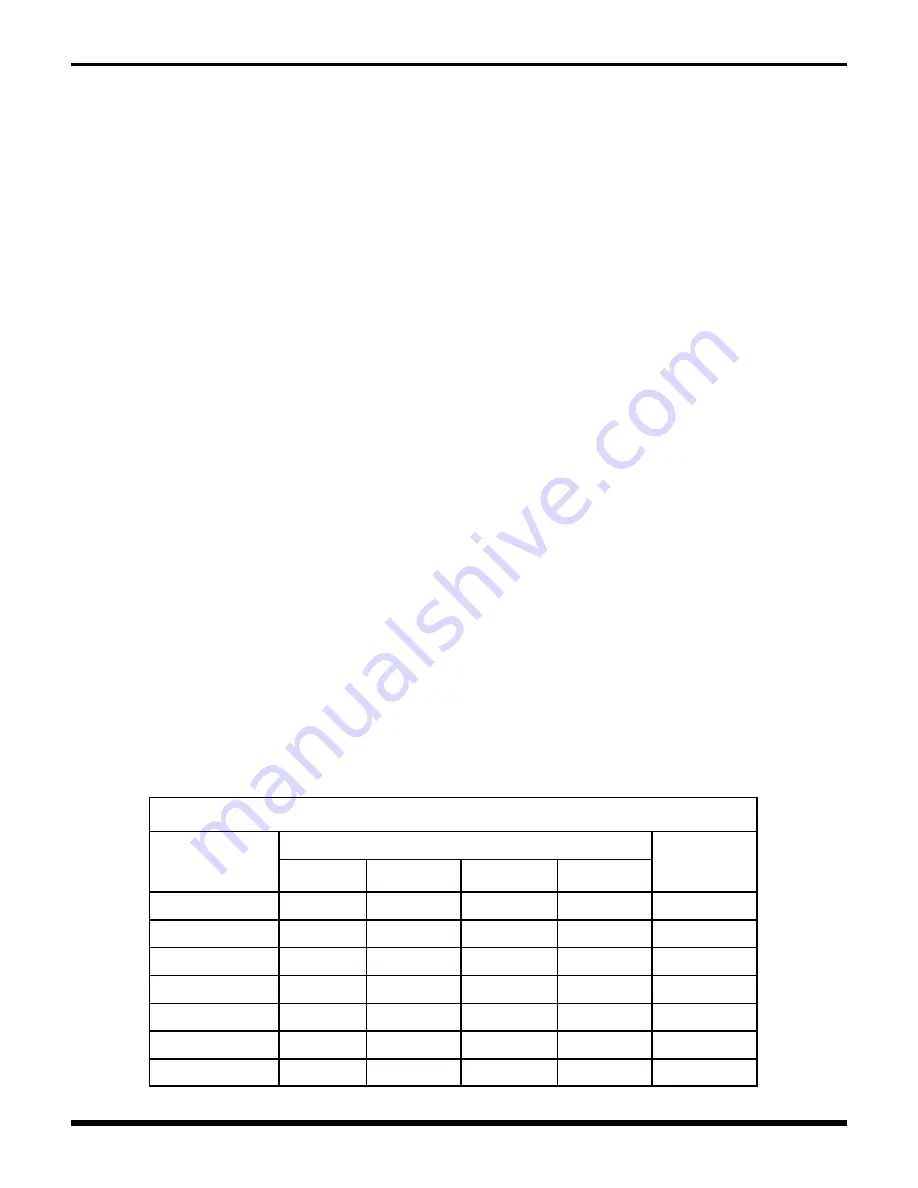

Table 1

Flow Capacity Tests –

Port

“

OUT

”

Valve Setting PSI

Test Ranges and Time

Test Volume

Cu. In.

Fill PSI

Maximum

Time

-

Sec.

Exhaust

PSI

Maximum

Time

-

Sec.

0

-

30

0

-

15

2

0

-

15

2

450

0

-

35

0

-

15

2

0

-

15

2

450

0

-

65

0

-

50

1

50

-

10

2

225

0

-

100

0

-

50

1

50

-

10

2

225

0

-

125

0

-

50

1

50

-

10

2

225

0

-

150

0

-

50

1

50

-

10

2

225

0

-

175

0

-

50

1

50

-

10

2

225