4

I M P O R T A N T

READ THE SAFETY INSTRUCTIONS in the 7536 tool manual carefully. While a small amount of wear and marking will

naturally occur through normal and correct use of mandrels, they must be regularly examined for excessive wear and

marking, with particular attention to the head diameter, the tail jaw gripping area of the shank or heavy pitting of the

shank and any mandrel distortion. Mandrels which fail during use could forcibly exit the tool. It is the customer’s

responsibility to ensure that mandrels are replaced before any excessive levels of wear and always before the

maximum recommended number of placings. Contact your Avdel representative who will let you know what that figure

is by measuring the broach load of your application with our calibrated measuring tool. These tools can also be

purchased under part number 07900-09080, supplied with all necessary information for testing.

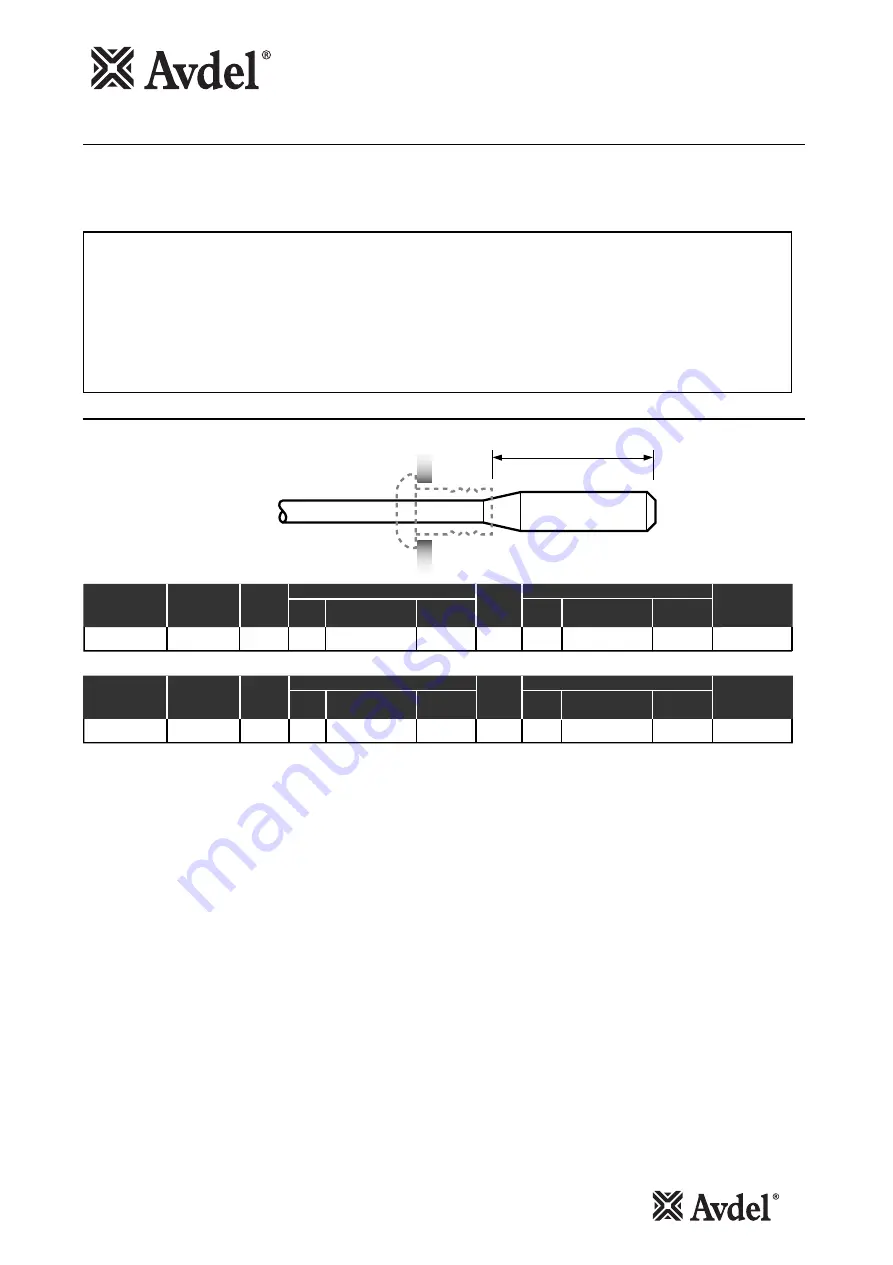

Mandrel Head Types and ‘P’ Length

AVLUG

®

P

1/16"

AVLUG

®

FASTENER

REFERENCE

NUMBER

STANDARD MANDREL- GREEN

1st OVERSIZE MANDREL- YELLOW

'P'

HEAD

MAXIMUM

MANDREL PART

NUMBER

SPRING PART

NUMBER

27-1

0.565

0.381

07155-06702

07154-06802

'P'

HEAD

MAXIMUM

MANDREL PART

NUMBER

0.515

HOLE

SIZE

AS REC

0.335

07154-06602

HOLE

SIZE

+

0.005

1/16"

AVLUG

®

FASTENER

REFERENCE

NUMBER

STANDARD MANDREL- GREEN

1st OVERSIZE MANDREL- YELLOW

'P'

HEAD

MAXIMUM

MANDREL PART

NUMBER

SPRING PART

NUMBER

27-1

1.44

9.68

07155-06702

07154-06802

'P'

HEAD

MAXIMUM

MANDREL PART

NUMBER

1.31

HOLE

SIZE

AS REC

9.02

07154-06602

HOLE

SIZE

+

0.10

Use of Mandrels

Mandrels and mandrel follower springs need to be selected to suit the fastener type and size as well as the size of the hole in the

application. Use of the wrong mandrel could increase the risk of breakage and the wear of the mandrel head. Feeding problems could

occur if the wrong mandrel follower spring is used.

Summary of Contents for 7536

Page 5: ...5 Notes...