Owner Installation Instructions

Axess® Pro Series 3100

15

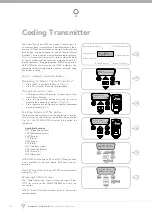

To Desired

CLOSE Limit,

SET

To Desired

OPEN Limit,

SET

17

fi g

16

fi g

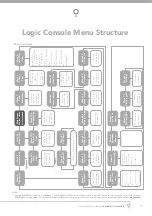

Setting Limits via Logic Console

Step 7 - Setting Travel Limits

Turn on the power to the opener. The controller will

go through a start up sequence.

After a short delay the MAIN SCREEN

(Fig. 16)

will

be displayed. If this is the fi rst time the Axess® Pro

Series 3300 is being used, the MAIN SCREEN should

enter into limit set mode and the blue close LED

will be fl ashing. If the display shows that an input is

active, then rectify the situation before continuing

with the procedure for setting the travel limits. Press

and hold the CLOSE button - the shutter should start

closing.

If the shutter opens, release the CLOSE

button and press the STOP button once

to change the motor’s direction. Press and

hold the CLOSE button until close position

of the shutter is reached.

If the shutter overshoots, press the OPEN

button to move the shutter in the open

direction.

When the shutter is at the desired close position, press

the SET button to record the close limit position. The

display will change and the green open LED will start

to fl ash

(Fig. 17)

.

Press and hold the OPEN button to open the shutter.

When the shutter is at the desired open position,

release the OPEN button

If the shutter overshoots, press the CLOSE

button to move the shutter in the CLOSE

direction.

WARNING!

Once the next step is performed, the

shutter will automatically close and open to calculate

travel time settings. Keep persons and objects clear of

the shutter.

Press the SET button to store the open limit. The

shutter will now automatically close and open to

calculate the travel time settings. After this, If PE Beams

are installed, the opener can be operated with the

OPEN or CLOSE button on the logic console or from

the transmitter. Otherwise, the controller will be loaded

with “Safety Close Mode.” (Page 28)

1.

2.

»

»

3.

4.

»

5.