TJ300

06

MAINTENANCE

NOTICE

:

Use only a good grade of

hydraulic oil. Never use brake fluid, motor

oil, transmission fluid, turbine oil or any other

fluids.

ISO-VGG22 equivalent hydraulic oil is

recommended.

IMPORTANT: NO RESPONSIBILITY IS

ACCEPTED FOR INCORRECT US OF

THIS PRODUCT.

1. Remove hydraulic unit cover, if cover is

provided.

2. With the jack in the fully lowered and

level position, remove the oil filler plug.

3. Recommended oil level should be just

covering inner cylinder as seen from the

oil filler plug hole.

4. Do not overfill. Always fill with new,

clean hydraulic jack oil as

recommended above.

5. Replace oil filler plug. Then replace the

unit cover.

DO NOT touch the safety overload

valve

(fig.2.V).

Lubrication and cleaning

Periodically clean and lubricate all

moving parts and pivot points.

Air Venting Procedures

1.

With the jack in the fully lowered

position and release valve open,

remove the oil filler plug.

2.

Insert handle into the handle sleeve

and pump rapidly several times.

Replace oil filler plug.

3.

Turn the release valve clockwise to

the close position.

4.

Pump the handle until the lift arm

reaches the maximum height and

continue to pump several times to

remove the trapped air in the

system.

5.

Turn the release valve counter

clockwise one full turn and lower the

lift arm to the lowest position, using

force on

the

saddle if necessary.

6.

Carefully and slowly pinch the oil

filler plug to release pressurised air.

7.

Repeat above steps until trapped air

is completely vented.

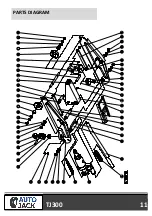

Summary of Contents for TJ300

Page 11: ...TJ300 09...