USER MANUAL

Scissor

ASLP-3005

ASLP-3005/IG

ISSUED 04-02-2004

AUTEC Hefbruggen bv

Industrieterrein Ijsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel:+31 348 477000 Fax:+31 348 475104 E-mail: [email protected]

MAIN SWITCH (7)

Position 0 :

In this position, the lift is no

longer live, if necessary, a lock may be

placed on the main switch, so as to

prevent unauthorised access or

operation of the lift.

Position 1 :

When the

main switch

is

in the position “1”, the electric circuit

becomes live.

EMERGENCY STOP BUTTON (4)

Take care to see that this is fully in the

off position. If this is pressed, it is not

possible to run the lift.

LIFTING MOTION BUTTON (6)

On pressing this button, the motor and

the lifting motion valve become live, and

the lift will rise.

LOWERING MOTION BUTTON (5)

On pressing this button, the lowering

motion valves will become live, and the

lift will fall to the safety height of 400

mm from the ground.

SAFETY BUTTON FOR DOWNWARD

MOVEMENT (7)

On pressing this button, the horn, and

after a few seconds, the valves must

become live. The lift will now complete

the last 400 mm of the downward

movement. And the lift will

simultaneously synchronise once it

reaches the lowest position.

SEQUENCE OF OPERATIONS

•

Positioning of the vehicle

Park the vehicle in the middle of the

platform and if necessary push out

the extension pieces of the platform.

•

Support points

Place the rubber supports under the

car-jack support points of the

vehicle.

•

Lifting

Set the main switch

(7)

in position 1

and if necessary, turn the

emergency stop button in the proper

position. Press the lifting button

(6)

until the desired height is reached.

The lift will now stop automatically.

•

Lowering

Press the switch for the lowering motion

(5).

The lift will now sink to 400 mm above the

ground. Check whether the safety area under and around the lift is free of personnel and

obstacles of any kind. Now let the lift sink lower by pressing the safety button for the

lowering action

(1)

.

•

Emergency Lowering

If there is a power failure, one can lower the lift in the following manner :

1. In the control cabinet, the two lowering-motion valves

(Fig. 18)

must be

simultaneously opened by turning them in the anti-clockwise direction.

2. When the platform has been lowered completely, the valves must be closed tight

after the platform has been fully lowered.

Fig. 18

7. MAINTENANCE

The lift must be inspected once a year according to the CE Regulations, by a person who

is certified to do the same. In addition, preventive maintenance must also be carried out

once a year on the lift (ask for AUTEC maintenance contracts).

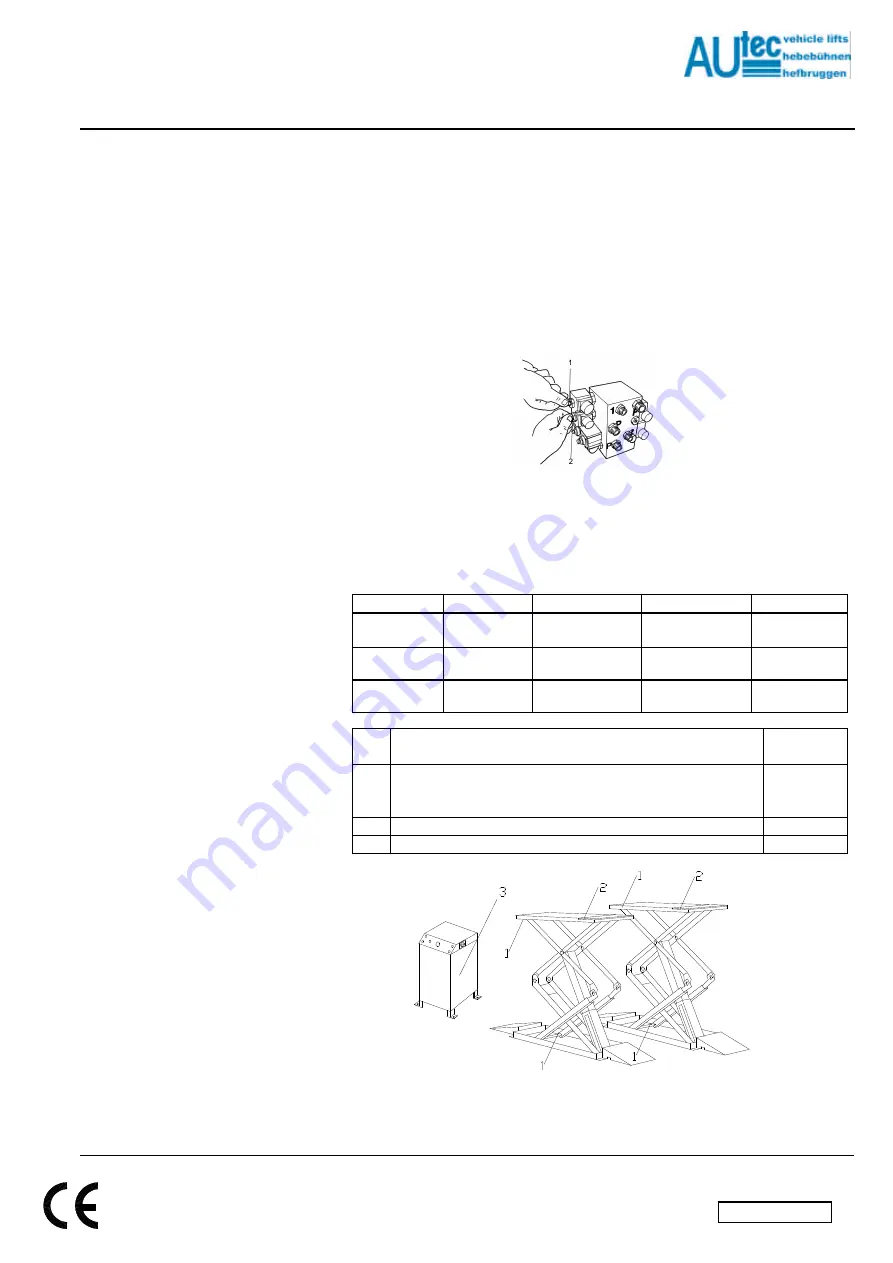

We recommend the following lubricants for lubricating the lift (see Fig. 19) :

No.

Texaco

Shell

ESSO

Castrol

1. Guides

Teflon spray

Teflon spray

Teflon spray

Teflon spray

2. Guide

support plates

Molytex EP 2

Alvania HDX vet 2

Multipurpose vet +

moly

MS3 grease

3. Hydraulic

system

Rando 32

Tellus 32

Nutto H32

HYSPIN HWS

32

No.

Lubricating points

Lubricating

interval

1. Guides for the sliding block (only lubricate the guides on the upper

side of the guide blocks. Do not lubricate the underside, because

this accumulates dirt).

3 months

2. Guides for the support plate extension pieces

3 months

3. Replacement of hydraulic oil

5 years

Fig. 19

en/TA-ASLP-3005-06