22

Assembly Instruction

FVM2

A

SSEMBLY

OF

A

PREPROGRAMMED

SET

Assembly locking drive FVM2

Mount the locking drive

FVM2

- as described below:

Determine fastenings.

Produce drill holes with appropriate cross-section.

For concealed mounting inside profi

les produce

the milling layouts. Please refer to the above-mentioned

hole layout drawings and mill layouts drawings

(see chapter „I

NSTALLATION

STEP

3“ or project-specifi c

documents and drawings).

Carefully clear away drilling swarfs to prevent

seals from being damaged.

Avoid surface scratches, for example by using

masking tape.

!

Mount the locking drive

FVM2

with screws

and

washers

in the pre-cut window frame.

Secure fasteners against loosening; i. e. by applying

removable thread-locking compound such as “Loctite”.

Switch on

the

control voltage

at locking drive

FVM2

and at the opening drive

-

in

CLOSE

direction.

First the opening drive moves in

CLOSE

direction, then

moves the locking drive

FVM2

.

Check whether the traverse path of the locking drive

FVM2

with the traverse path of the on-site locking bar

moves

synchronously.

If necessary, correct the locking stroke and the locking

position - with the

DIP

switches.

Move locking drive

FVM2

and opening drive in

OPEN

direction.

Switch off

the

control voltage

from the locking

drive

FVM2

and from the opening drive.

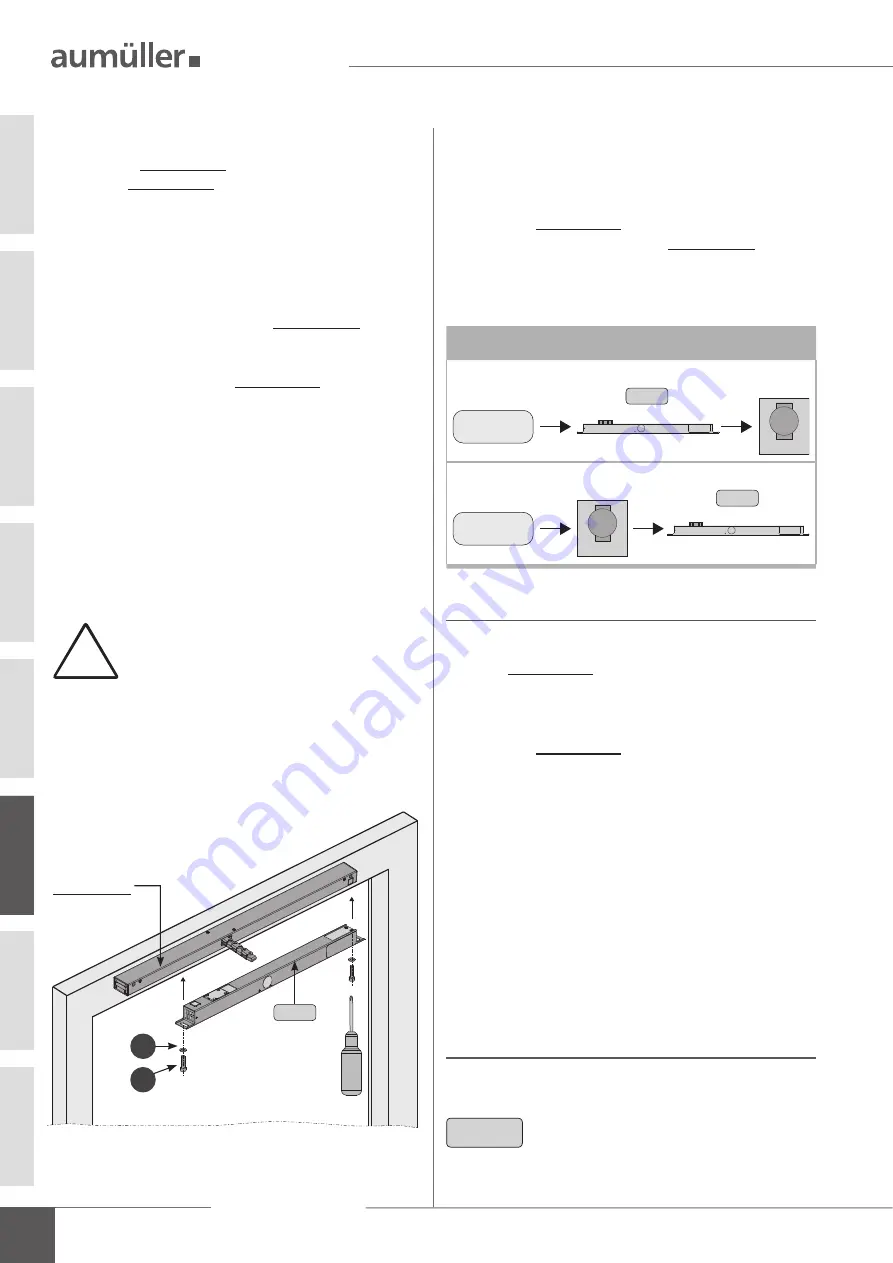

Sequence control:

24V DC

M

24V DC

M

Open

Locking drive

Opening

drive

Close

Locking drive

Opening

drive

FVM2

FVM2

opening drive

is unhinged

4

5

FVM2

RA

Test run: locking drive FVM2

Close the casement manually. During the test run

press the casement fi xed to the frame.

Switch on

the

control voltage

at locking drive

FVM2

and at the opening drive

-

in

CLOSE

direction.

Move locking drive

FVM2

and opening drive in

OPEN

direction.

Ensure the easy movement of the casement.

Open the casement manually.

Test run

Hinge opening drive on casement.

Make mechanical settings in accordance with „Assem-

bly and Commissioning Instructions“ of the drives.

Switch on

the

control voltage

at locking drive

FVM

and at the opening drive -

in

CLOSE

direction.

Check sequence control.

Ensure the easy movement of the casement.

N

OTE

When subsequent programming with

UniPC

the same assembly steps as

in the installation must be carri-

ed out with

preprogrammed set

(see separate: Installation Instructions for

UniPC).

06