19

Instruction Manual

3.

OPERATING INSTRUCTIONS

3.1

T

RANSPORT

INSTRUCTIONS

Strong, integrated beams (1) within the framework of the unit mean

that installation can be easily performed with use of a fork-lift truck.

Fig. 3.1

Integrated beams

Connecting the compressor to the prime mover is done by Atlas

Copco technicians. The same applies to any disconnecting.

Leave the cover in place during transport.

3.2

B

EFORE

STARTING

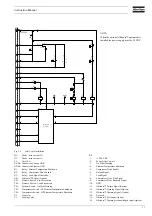

1. Remove the air receiver drain plug and open the drain valve (

, DV) to drain possible condensate. Close the valve when all

condensate has been drained or when oil comes out. Reinstall the

drain plug. The interval between draining operations may be

determined by experience, as the amount of condensate depends

on the operating conditions. It may be necessary to keep the side

panel(s) removed during operation to decrease the amount of

condensate.

2. Check the level of the compressor oil. The pointer of the oil level

gauge must register in the upper extremity of the green range.

Add oil if necessary. See section

for the oil to be used.

Normally, there is no need to add oil between two oil changes; if

there is, check the source of oil consumption.

3. Empty the dust trap of each air filter (

, AF). See section

.

4. Attach the air line(s) to the closed air outlet valve(s).

3.3

S

TARTING

Ascertain that the air receiver pressure is fully released before

starting.

Close the main switch and start the prime mover (

, PM)

according to the instructions of the manufacturer.

3.4

C

OMPRESSION

STARTING

1. When the prime mover is running smoothly, energize the loading

solenoid valve (

, LV) by pressing the loading push

button.

2. As soon as the unloading pressure registers on working pressure

gauge, the unit runs unloaded.

3. Open the outlet valve(s) (

, AOV).

3.5

D

URING

OPERATION

Regularly carry out following checks:

1. If the vacuum indicator switch (

, VIS) gives a warning

signal, stop the unit and service the air filters (

, AF). See

.

2. Check the compressor oil level. The pointer of the oil level gauge

must register in the upper extremity of the green range (

SG). If the level is too low, stop the unit and wait approx. 10

minutes to allow the air to escape from the oil. Add oil if

necessary. See section

for the oil to be used.

3. Check that the regulating valve (

, RV) is correctly

adjusted.

4. Check the air outlet temperatures of the compressor elements,

which are shown on the temperature gauges (

1

and

TG

2

).

Reinstall the side panel after checking.

3.6

S

TOPPING

1. Close the air outlet valve(s) (

, AOV).

2. Switch to noload condition and run the unit for some minutes.

3. Stop the prime mover (

, PM) and open the main switch.

Avoid knocks and violent shaking during transport.

Before draining the air receiver, ensure that the

pressure is released by opening the air outlet valve(s)

(

Before removing the oil filler plug (

, FP), ensure

that the pressure is released by opening the air outlet

valve(s) (

, AOV).

(1)

No external force may be applied to the air outlet

valve(s), e.g. by pulling hoses or by connecting

equipment directly to the valve(s) (e.g. a water

separator, a lubricator, pipe extensions, etc.).

Before removing the oil filler plug (

, FP) ensure

that the pressure is released by opening the air outlet

valve(s) (

, AOV).

Summary of Contents for ORV 10

Page 1: ...ORV 10 ORV 12 ORX 10 ORX 12 Instruction Manual for Portable Compressors English ...

Page 2: ......

Page 43: ......