Oil system

Air pressure forces the oil from receivers (AR) through oil coolers (Co), filters (OF) and oil stop valves (Vs)

to compressor elements (E) and the lubrication points.

Oil stop valves (Vs) prevent the compressor elements from flooding with oil when the compressor is stopped.

Valves (BV) by-pass oil coolers (Co) when starting the compressor from a cold condition, so ensuring rapid

warming of the oil to normal working temperature.

In air receivers (AR) most of the oil is removed from the air centrifugally. Almost all of the remaining oil is

removed by the separator elements.

2.3

Cooling and condensate system

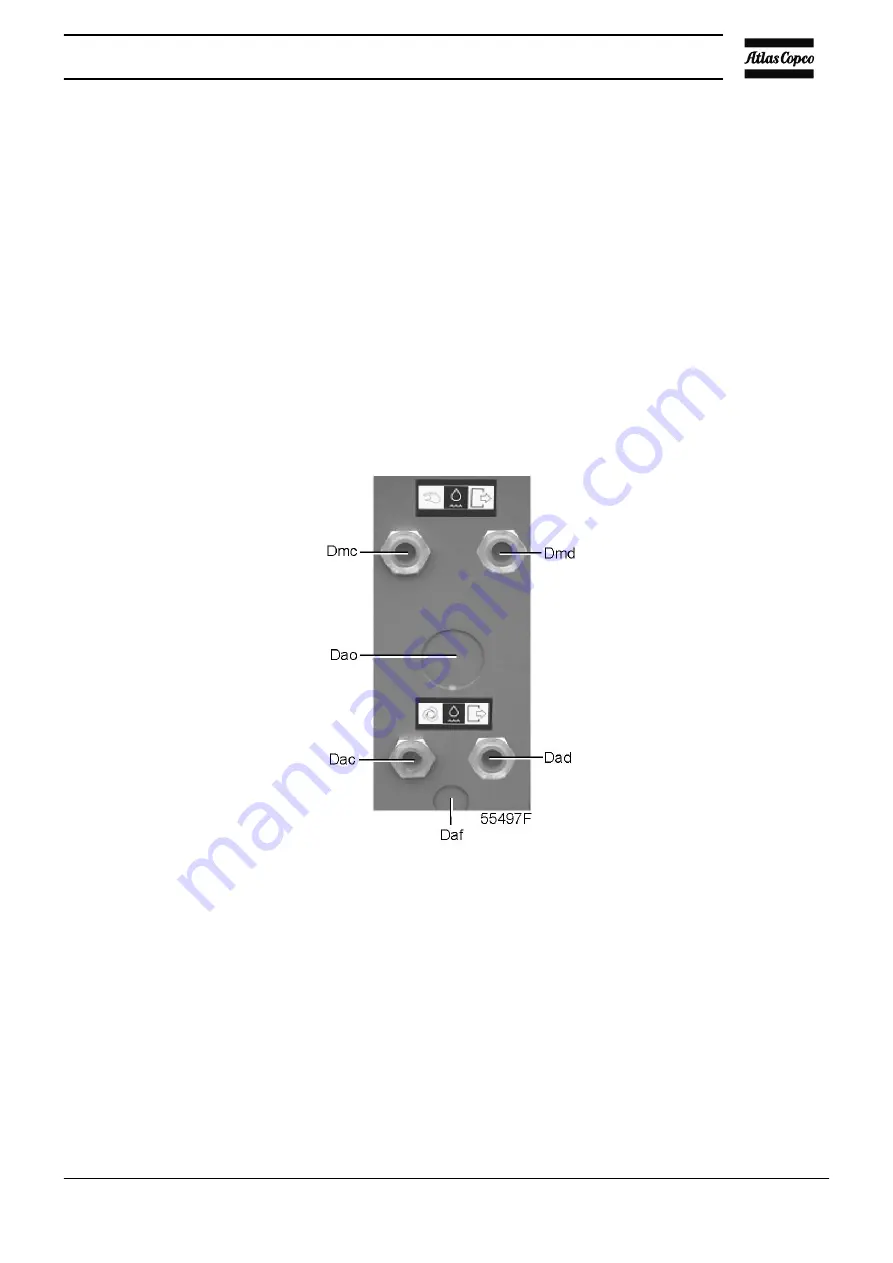

Condensate drain system

Condensate drains of GA 90 up to GA 160

Instruction book

2920 1475 06

17

Summary of Contents for GA110

Page 1: ...GA 90 GA 110 GA 132 GA 160 GA 200 GA 250 GA 315 ...

Page 2: ......

Page 17: ...Flow diagram of GA200 GA250 and GA315 60 Hz Instruction book 2920 1475 06 15 ...

Page 30: ...Menu flow for GA 90 up to GA 315 simplified example Instruction book 28 2920 1475 06 ...

Page 57: ...Dimension drawing of GA90 110 water cooled Instruction book 2920 1475 06 55 ...

Page 60: ...Dimension drawing of GA200 250 and GA315 60 Hz air cooled Instruction book 58 2920 1475 06 ...

Page 64: ...Compressor room example of GA 90 up to GA 160 water cooled Instruction book 62 2920 1475 06 ...

Page 76: ...Suspended solids Non soluble particles size 1 mm 10 ppm Instruction book 74 2920 1475 06 ...

Page 98: ...Filler and drain plugs on GA 200 up to GA 500 compressors Instruction book 96 2920 1475 06 ...

Page 102: ...Position of oil filter on GA 200 up to GA 500 Instruction book 100 2920 1475 06 ...

Page 133: ...Instruction book 2920 1475 06 131 ...

Page 134: ......

Page 135: ......