LZL03-L-P-AC

Safety Information

© Atlas Copco Industrial Technique AB - 9834 4045 00

7

Description

Value

Definition

Equipment category

Group II

2

High level of pro-

tection

• zone 1 (gas)

• zone 2 (gas)

• zone 21 (dust)

• zone 22 (dust)

Atmosphere

G

Atmosphere con-

taining Gas, Va-

pors or Mist

D

Atmosphere con-

taining Dust

Safety design

h

Mechanical prod-

uct

Gas group

IIC

Hydrogene/ Acety-

lene

IIB

Ethylene

Max surface tem-

perature in

Gas

at-

mosphere

T1

= 450°C

T2

= 300°C

T3

= 200°C

T4

= 135°C

T5

= 100°C

T6

= 85°C

Max surface tem-

perature in

Dust

at-

mosphere

Example tempera-

tures:

T85°C

T110°C

T120°C

T125°C

T240°C

Special restriction,

for example ambi-

ent temperature

range.

X

Temperatures

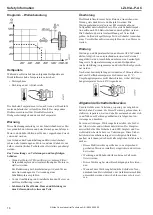

• The maximum surrounding temperature for which the

certification is valid is 40°C.

• 40°C is also the maximum allowed temperature of the

compressed air when it enters the product.

• If the product is installed in an equipment, the entire

equipment has to correspond to the guidelines 2014/34/

EU.

• Make sure that the compressed air fulfil our quality de-

mands (quality classes 2.4.3. and 3.4.4 respectively 3.5.4

acc. to ISO/DIS 8573-1:2010).

• Do not exceed maximum pressure of 6.3 bar, or as stated

on the product nameplate. Exceeding the operating pres-

sure can increase the surface temperature due to higher

rotating speed and the product can become an ignition

source.

Ex Classification

If the product is part of an assembly where the components

have different Ex classification, the component with the low-

est level of safety defines the Ex classification of the com-

plete assembly.

Explosion Prevention Guidelines

Cleanliness

• Make sure the product is kept clean from dust and dirt to

prevent increased bearing and surface temperature.

• If using a silencer: Make sure a silencer with a filtering

effect at the air outlet is installed to prevent any friction-

heated particles entering into the surrounding atmos-

phere.

Usage

• Make sure the product is earthed to the equipotential

bonding system of the workshop, for example through

accessories such as hoses and air-pressure connections.

• It is the responsibility of the user to make sure that the

product and all possible accessories, such as wrenches

and air connections, conform to the national safety regu-

lations for equipment used in potentially explosive areas.

Useful Information

Website

Information concerning our Products, Accessories, Spare

Parts and Published Matters can be found on the Atlas Copco

website.

.

ServAid

ServAid is a portal that is continuously updated and contains

Technical Information, such as:

• Regulatory and Safety Information

• Technical Data

• Installation, Operation and Service Instructions

• Spare Parts Lists

• Accessories

• Dimensional Drawings

https://servaid.atlascopco.com

For further Technical Information, please contact your local

Atlas Copco representative.

Caractéristiques techniques

Indice IP

L'indice IP des moteurs pneumatiques se réfère au carter mé-

canique conformément à la norme IEC 60529. L'indice IP ne

couvre pas la résistance à la corrosion ou à d'autres liquides

autres que de l'eau douce potable.