- 44 -

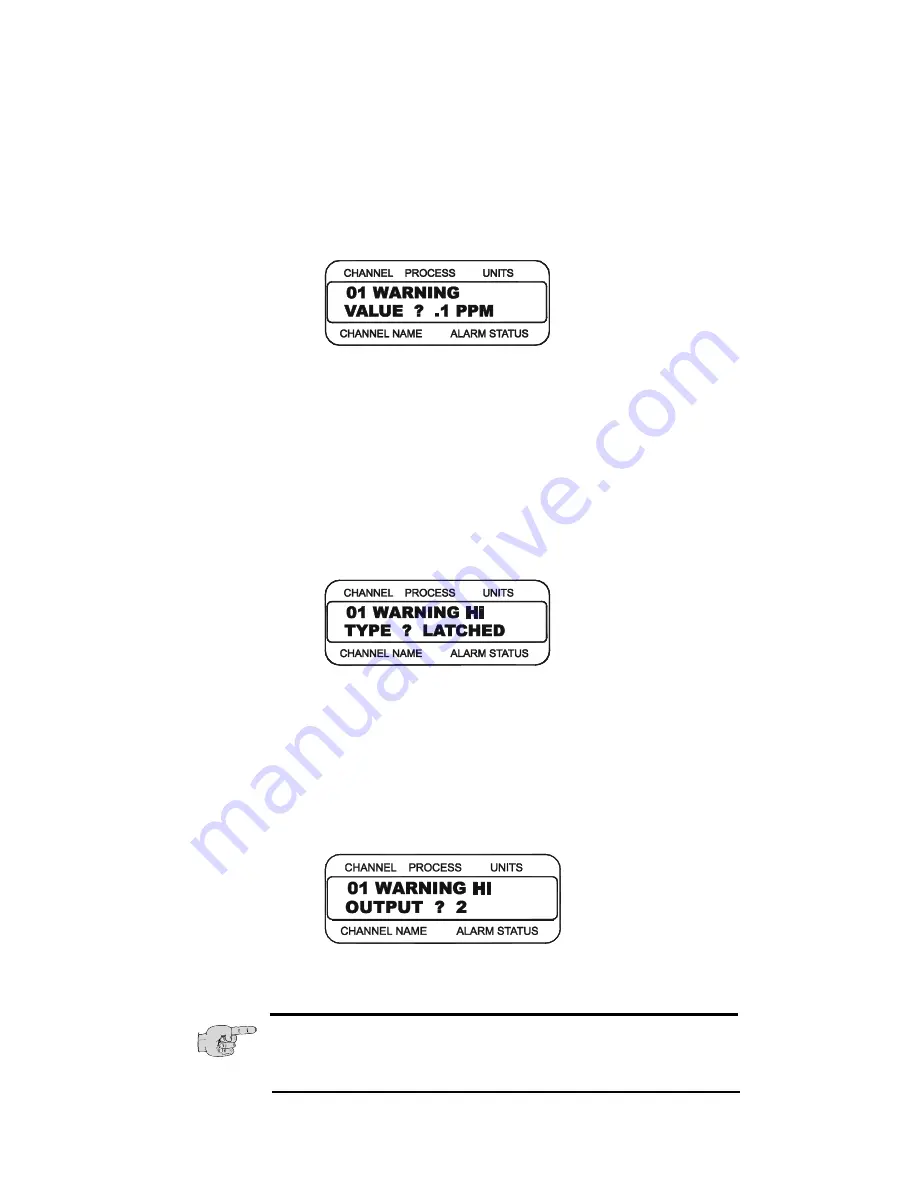

Warning Value

This menu lets you set the Warning band width, a positive and negative warning

point relative to the setpoint. If the setpoint changes, the warning points also

change. You can assign separate digital outputs to Hi and Lo Warnings.

Selectable Values: 0 to 255, 35.5, 2.55, .255 or .0255, depending on the way

you set up the Input menus.

Warning High

This menu lets you disable the warning Hi function or set it to the alarm functions.

(The Warning Hi activates if the process value (PV) rises above the deviation

band value, and remains active until the PV goes below the deviation band value

minus the deadband value.)

Selectable Values: Latched, Unlatched, or Off

Warning High Output Number

This menu assigns a digital output which activates when the channel is in high

deviation alarm. The digital output only activates if you have set the high

deviation alarm to On.

Selectable Values: 1 to 34, None

NOTE

All digital outputs are combined. Therefore you can assign more than

one alarm to the same output number, and the output will be On if any

of those alarms is On.

Summary of Contents for Scan Alarm C14

Page 10: ...10 Mechanical Installation Figure 1 Wall Mount Enclosure Dimensions ATI 0247...

Page 11: ...11 Figure 2 Panel Mount Mounting Dimensions ATI 0257...

Page 13: ...13 Figure 5 2 Relay Module Enclosure Dimensions 80 0040...

Page 14: ...14 Figure 6 4 Relay Module Enclosure Dimensions 80 0036...

Page 16: ...16 Figure 7 A12 UniSens Connection ATI 0256 CHANNEL 1 SHOWN...

Page 17: ...17 Figure 8 B12 2 Wire Connections ATI 0249...

Page 18: ...18 Figure 9 C12 17 Combustible Transmitter Connections ATI 0251...

Page 19: ...19 Figure 10 Powered 4 20mA Input Transmitter Connections ATI 0250...

Page 20: ...20 See Appendix 2 in back of manual for The Relay Module Wiring Diagram...

Page 28: ...28 See Appendix 3 in the back of the manual For the Scanner Software Flowchart Diagram...

Page 50: ...50 APPENDIX 1 General Customer Connections Diagram ATI 0248...

Page 51: ...51 Appendix 2 Relay module wiring diagram ATI 0271...