8

e n G l i s H

AFM

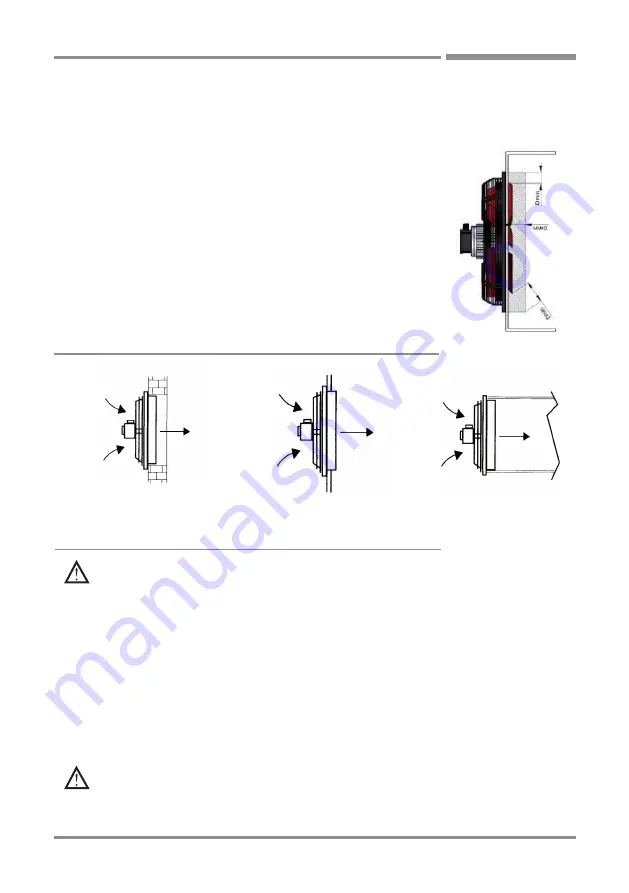

WAll MountinG

pAnel MountinG

ducts MountinG

•

Fans with prominent impeller shall be mounted so that the minimum

distance (dmin) between the impeller and the other parts of the equipment,

where fan is fixed, shall never be less than 20mm, Fig. 3.

4. cleAninG And MAintenAnce

3.1 exAMples oF instAllAtion

CAUTION: THE INTERVENTION MUST BE PERFORMED BY QUALIFIED PERSONNEL.

IN ORDER TO GUARANTEE FAN CORRECT OPERATING, REGULAR MAINTENANCE IS NECESSARY.

•

periodically check for and remove any dust deposits on the motor which may undermine its operation due to

insufficient cooling. For this operation we recommend using a dry brush or compressed air jets.

•

As general rule, on respecting the limits of use and the standard operating conditions, carry out, at least four

times in a year, the following operations:

•

verify levels of noise and vibrations; anomalous values are index of malfunction;

•

control the presence of corrosion on the structure;

•

clean the machine and, mainly, the impeller; so to avoid dust deposits that can be a source of risk. dust

deposits on all components shall not exceeds 2 mm in thickness;

•

verify and restore the correct locking of bolts;

•

note: during the cleanness of the impeller, take care to not endanger its balance.

•

in any case, do not remove the impeller; its removal void its compliance with directive and all warranties.

CAUTION: THE MOTOR AND THE ELECTRICAL PARTS MUST NOT BE SUBMERGED IN WATER OR

OTHER LIQUIDS

Fit back the components perfectly clean and dry in reverse order with respect to the disassembly

sequence. restore the electrical connections.

Fig. 3

Summary of Contents for AFM

Page 10: ...10 AFM IT A LI A NO ...