78

GRINDER MIXER ADJUSTMENTS

lock bolts when processing, otherwise the roll gap

will open and feed particle size will increase.

To check the roll gap, remove the 20 inch magnet

(See Figure 148) from the hopper throat. Using a

feeler gage, check the current roll gap with the

eccentric roll handle down on the stops and the

eccentric lock bolts snugged down. Be sure to

check the roll gap at the front and back of the rolls.

Also rotate the rolls to check several different

places on the roll diameter, as there may be 0.001

to 0.002 inch difference in the concentricity of the

rolls.

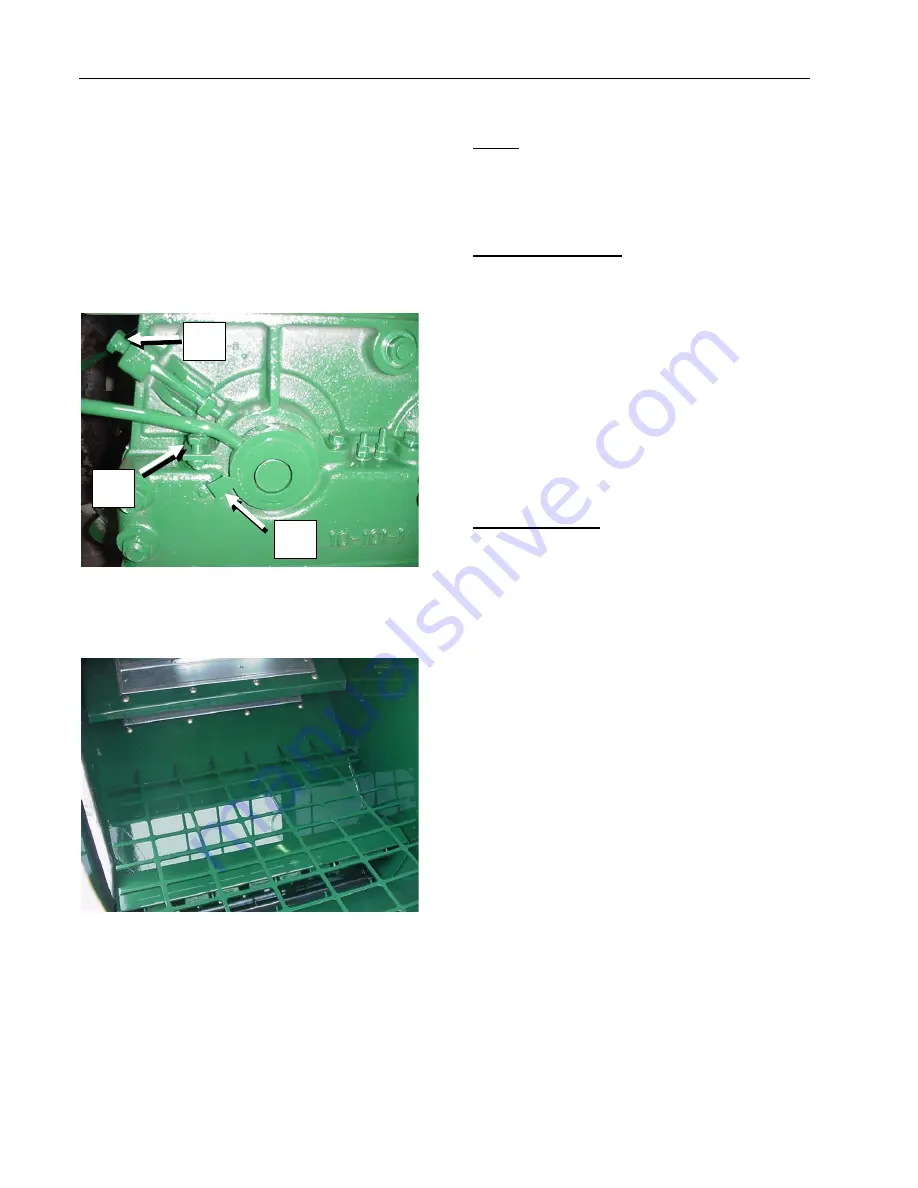

Figure 147 - Rollermill Housing Eccentric Bearing. A

- Eccentric Lock Bolts, B - Pointer Gauge, C - Stop

Bolts.

Figure 148 - Removing Magnet To Check Roll

Spacing.

To change the minimum roll gap, loosen the

eccentric lock bolts and pull the eccentric roll

handle up and out of the way. Loosen the jam nuts

on the 1/2 inch stop bolts (See Figure 149) and turn

both the front and rear stop bolts evenly, up for a

wider roll gap and down for a smaller roll gap. Lower

the eccentric roll handle to the stop bolts and re-

tighten the eccentric lock bolts. Re-check the roll

gap and repeat as necessary until the desired roll

gap is attained. Be sure to re-tighten the jam nuts

on the stop bolts when finished.

NOTE:

Rolls must not be set closer than 0.008 inch

gap. Never adjust the minimum roll gap setting with

the tractor PTO engaged. The rollermill rolls will be

severely damaged if they ever touch while the PTO

is engaged.

R

OLL

P

ARALLELISM

If the roll gap is different from front to back on the

rolls, the rolls are out of parallel and need to be

adjusted. This can occur from the eccentric roll

handle getting bent or twisted, or uneven roll wear

from not keeping the hopper full across the whole

width while processing. To adjust roll parallelism,

reset one stop bolt up or down. Be certain to push

down on each corner of the eccentric roll handle

when tightening the eccentric lock bolts to ensure

both sides of the handle are in contact with the

stops. The eccentric roll handle may have to be

twisted to accommodate an excessive stop bolt

adjustment.

R

OLL

S

CRAPERS

Roll scraper clearance needs to be monitored as

the rolls wear and should be adjusted after changes

in a minimum roll gap setting or when replacing

rolls. The main drive roll scraper should be set at

0.006 inch clearance and the eccentric roll should

be set at 0.050 inch clearance. Be sure the

minimum roll dap is set and the rolls locked in place

before setting the scrapers.

To adjust the roll scrapers, loosen the jam nuts on

the scraper adjustment bolts (See Figure 149). Turn

the adjustment nut clockwise to bring the scraper

closer to the roll. Turn the roll by hand while

adjusting the scraper. When the scraper contacts

the roll, back the adjusting nut off slightly until no

scraper to roll contract can be heard. On the

opposite side of the mill (front to back) turn the

adjustment nut on the same scraper until the

scraper contacts the roll. Back the adjustment nut

off slightly until no scraper to roll contract can be

heard. Recheck the side of the mill you started on

and repeat the procedure if further adjustment is

needed.

C

A

B

Summary of Contents for CATTLEMAXX 6105

Page 7: ...TABLE OF CONTENTS 5 ...

Page 14: ...12 INTRODUCTION Figure 5a Safety Decals ...

Page 22: ...20 PREPAIRING THE GINDER MIXER FOR OPERATION Figure 15 PTO Support ...

Page 27: ...OPERATION OF GRINDER MIXER 25 cleaned out Keep all bystanders away from the machine ...

Page 42: ...40 LUBRICATION Figure 70 Hammermill engaging pin shields removed for clarity ...

Page 49: ...SERVICE 47 Figure 96 Belt Removal Shields Removed For Clarity B C ...

Page 78: ...76 OPERATION OF CATTLEMAXX Figure 143 Hopper Inspection Window ...