* Size rounded off to the nearest foot

BUILDING DIMENSIONS

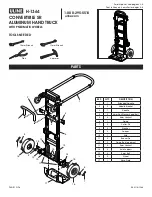

CAUTION: SOME PARTS HAVE SHARP EDGES. CARE

MUST BE TAKEN WHEN HANDLING THE VARIOUS PIECES

TO AVOID A MISHAP. FOR SAFETY SAKE, PLEASE READ

SAFETY INFORMATION PROVIDED IN THIS MANUAL

BEFORE BEGINNING CONSTRUCTION. WEAR GLOVES

WHEN HANDLING METAL PARTS.

714890108

Model No.

WH1014-D1

Owner's Manual & Assembly Instructions

ST01

Exterior Dimensions Interior Dimensions Door

*Approx. Foundation Storage Area (Roof Edge to Roof Edge) (Wall to Wall) Opening

Size Size Sq. Ft. Cu. Ft. Width Depth Height Width Depth Height Width Height

10' x 14' 121" x 160 1/4" 129 852 123 1/4" 162 3/4" 87 7/8" 118 1/4" 157 1/2" 86 5/8" 55 1/2" 60"

3,0m x 4,0m 307cm x 407cm 12,0m

2

24,1m

3

313cm 413cm 223cm 300cm 400cm 220cm 141cm 152cm