507607-03

Issue 1827

Page 5 of 23

Line Set Isolation

The following illustrations demonstrate procedures that

ensure proper refrigerant line set isolation. Figure 7 shows

how to install line sets on horizontal runs. Figure 8 shows

how to make a transition from horizontal to vertical. Figure

9 shows how to install line sets on vertical runs.

Table 2. Refrigerant Line Set Diameters (in.)

Model

16 SEER

Liquid Line

Suction Line

24

3/8

3/4

36

3/8

7/8

48

3/8

7/8

60

3/8

1-1/8

For lines longer than 50 ft., refer to long line set guidelines.

Brazing Connection Procedure

1. Cut ends of refrigerant lines square (free from nicks or

dents). Debur the ends. The pipe must remain round;

do not pinch end of line.

2. Before making line set connections, use dry nitrogen

to purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the

system.

3. Use silver alloy brazing rods (5% or 6% silver alloy

for copper-to-copper brazing or 45% silver alloy for

copper-to-brass or copper-to-steel brazing) which are

rated for use with R410A refrigerant.

4. Remove the Schrader core assemblies before brazing

to protect them from damage due to extreme heat.

Replace the cores when brazing is complete.

5. Remove light maroon washers from service valves

and shield light maroon stickers to protect them during

brazing. Wrap a wet cloth around the valve body and

copper tube stub to protect it from heat damage.

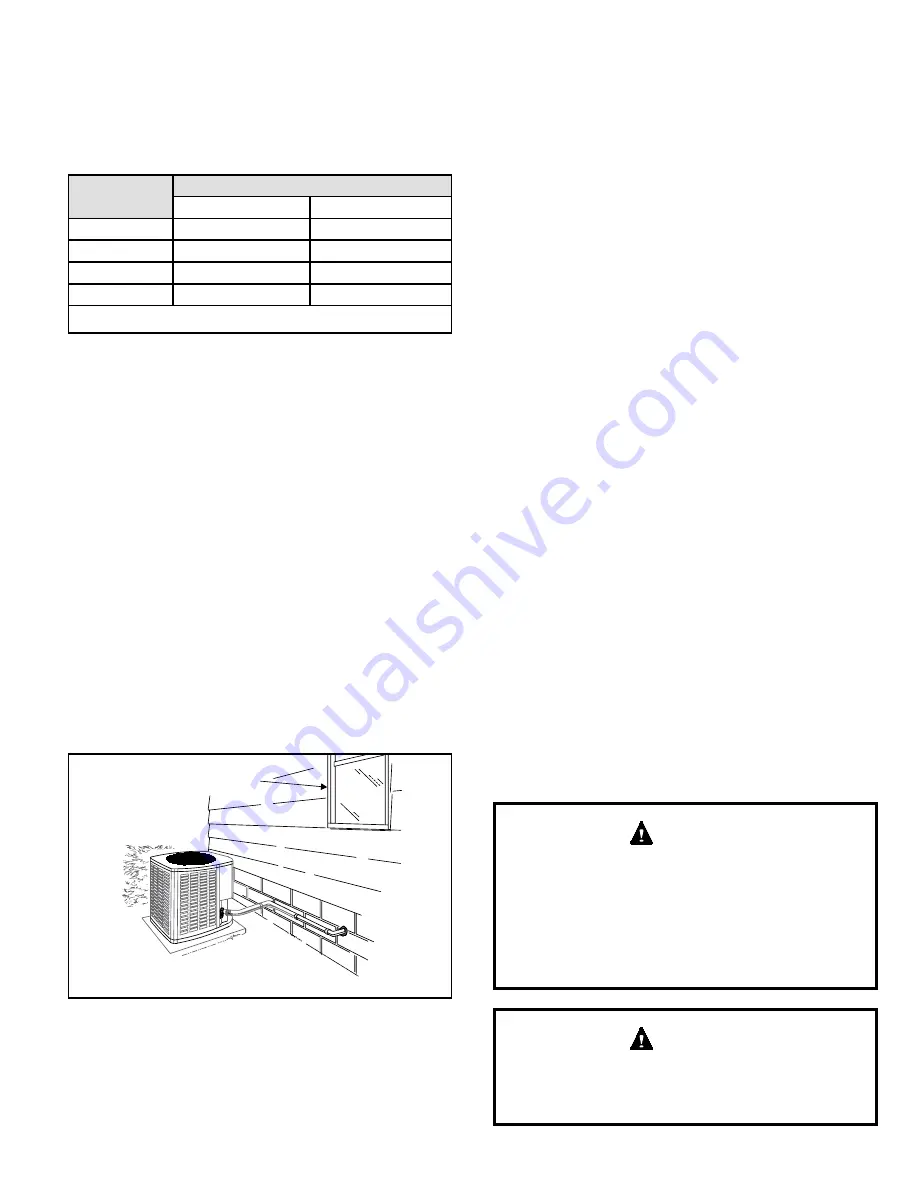

Install unit away

from windows

Two 90° elbows installed in lineset

will reduce lineset vibration

Figure 6. Outside Unit Placement and Installation

6. Braze the line set to the service valve. Quench the

joints with water or a wet cloth to prevent heat damage

to the valve core and opening port. The tube end must

stay bottomed in the fitting during final assembly to

ensure proper seating, sealing, and rigidity.

7. Install the thermal expansion valve which is sold

separately and which is approved for use with R410A

refrigerant in the liquid line at the indoor coil (see

Refrigerant Metering Device section).

Refrigerant Piping

If the 4SCU16 LS unit is being installed with a new indoor

coil and line set, the refrigerant connections should be

made as outlined in this section. If an existing line set and/

or indoor coil will be used to complete the system, refer

to this section as well as the section that follows entitled-

Flushing Existing Line Set and Indoor Coil.

If this unit is being matched with an approved line set

or indoor coil which was previously charged with R-22

refrigerant, the line set and coil must be flushed prior to

installation. If the unit is being used with an existing indoor

coil which was equipped with a liquid line which served as

a metering device (RFCI), the liquid line must be replaced

prior to the installation of the 4SCU16 LS unit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections).

Select line set diameters from Table 2 to ensure that oil

returns to the compressor. Size vertical suction riser

to maintain minimum velocity at minimum capacity.

Recommended line length is 50’ or less. Table 2 shows

the diameters for line sets up to 100’ although vertical lift

applications and trapping requirements need to be reviewed

for line sets over 50’; refer to long line set guidelines.

Installing Refrigerant Line

During the installation of an air conditioning system, it is

important to properly isolate the refrigerant line to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling, or floor) may cause objectionable noise when

vibration is translated into sound. As a result, more energy

or vibration can be expected. Close attention to line set

isolation must be observed.

When flushing existing line set and/or indoor coil, be

sure to empty all existing traps. Residual mineral oil can

act as an insulator, preventing proper heat transfer. It

can also clog the thermal expansion valve, reducing

system performance and capacity. Failure to properly

flush system as explained in these instructions will void

warranty.

CAUTION

If ANY refrigerant tubing is required to be buried by state

or local codes, provide a 6 inch vertical rise at service

valve.

CAUTION