Th

e convenience, environmental performance and effi

ciency are optimised to meet the

demands of ease-of-use and effi

cient pellet combustion. Ariterm Bionet has a vertical

convection system that reduces deposition, which allows the boiler to retain a high

coeffi

cent of effi

ciency in between servicing. Servicing need depends on pellet quality

and output effi

ciency (fuel consumption) and varies seasonally. Th

e large ash box

holds 20 litres and is easy to remove and empty.

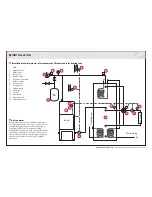

Bionet is made up of a fuel room with a smoke channel which is contained by an outer

shield containing 50 litres of water. When using pelletised fuel the heat from the

boiler is transferred directly to the water in the boiler tank. Th

e heat from the water in

the boiler tank can be transferred as hot water directly to, for instance, an accumulator

tank. Th

e heat can also be transferred to the heating system via a shunt connection

(optional).

Versatile supplemental heat

Th

e Ariterm Bionet can advantageously be adapted to existing waterborne heating sys-

tems. Th

e Bionet is an easy maintained, convenient and economic choice in combina-

tion with modern oil, fi rewood, heat-pump or solar-energy powered systems. Th

e 12

kW output is suffi

cient for most detached-house heating systems. For domestic hot

water needs, the Bionet can benefi cially be connected to a separate hot water storage

system pre-prepared for solar energy. Ariterm Bionet’s compact shape permits instal-

lation even in tight spaces.

Shunt connection

Th

e water from the boiler tank and the return water are mixed in the shunt vent to

ensure that the correct temperature is achieved in the radiator system in relation to the

outside temperature. Th

is mixing can be done manually or automatically through a

control unit (optional) to obtain the best possible fuel economy.

Chimney-sweeping

Sweep soot from the boiler via the combustion chamber door and cleaning hatch at

the top of the unit. Use a fl ue brush to clean all convection surfaces. Remove the

burner and clean the combustion chamber walls.

ATTENTION!

Always use caution when handling ashes, as some may still be glowing. Ash should be

kept in a fi re-proof container.

ARITERM SWEDEN AB

Installation, Operation and Maintenance - 2007.10.26- 4/12

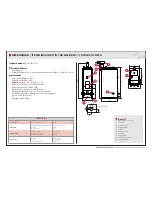

220

30

345

70

25

15

Expansion

DN 20

OPERATING PRINCIPLE

A shunt connection for

shunt valve ESBE TM20 is

available as an acces-

sory for connecting to an

oblique chimney inlet.

A Cross section picture of Bionet 12 and Ariterm pellet

burner BeQuem 12D.